Preparation method of highly-impermeable rubber concrete material

A rubber concrete and high-resistance technology, applied in the field of concrete materials, can solve problems such as poor impermeability, uneven distribution, and incomplete bonding of particle interfaces, so as to improve mechanical strength, impermeability, and roughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

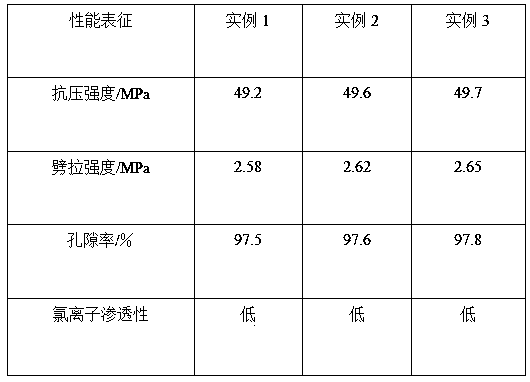

Examples

Embodiment Construction

[0025]In terms of parts by weight, weigh 45-50 parts of deionized water, 3-5 parts of aluminum chloride and 3-5 parts of 500-mesh aluminum powder, stir and mix them, and place them at 95-110°C for 2-3 hours to obtain Mixed solution and weigh 45-50 parts of deionized water, 15-20 parts of absolute ethanol, 10-15 parts of tetraethyl orthosilicate and 6-8 parts of 15% nitric acid by weight and place them in the Erlenmeyer flask , stir and mix and place at room temperature for 1-2 hours to obtain a modified solution. Add the modified solution dropwise to the mixed solution at a mass ratio of 1:10, and control the acceleration rate of the modified droplet to 2-3mL / min, after the dropwise addition is completed, stir and mix and evacuate and concentrate for 1-2 hours, control the vacuum degree to 25-30Pa, obtain a viscosity of 25-35Pa·s, and obtain the modified liquid base liquid; according to the mass ratio of 1:15, the Add 5% sodium hypochlorite solution dropwise into the modified...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com