Polymer cement waterproof coating and preparation method thereof

A waterproof coating and polymer technology, applied in the field of waterproof materials, can solve the problems of low tensile strength and elongation at break, and achieve the effects of improving tensile properties and bonding properties, improving tensile properties, and improving comprehensive properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

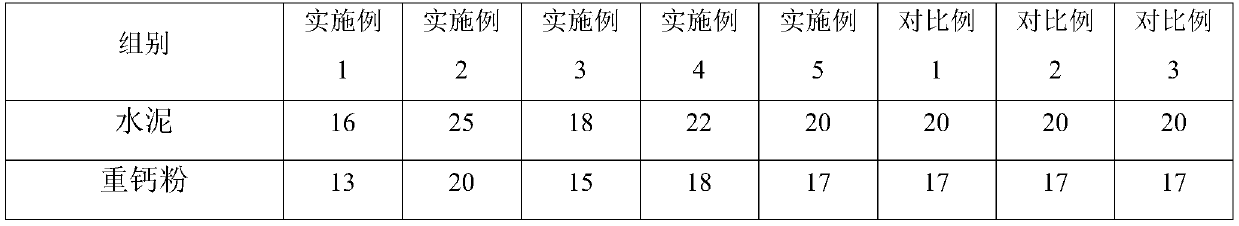

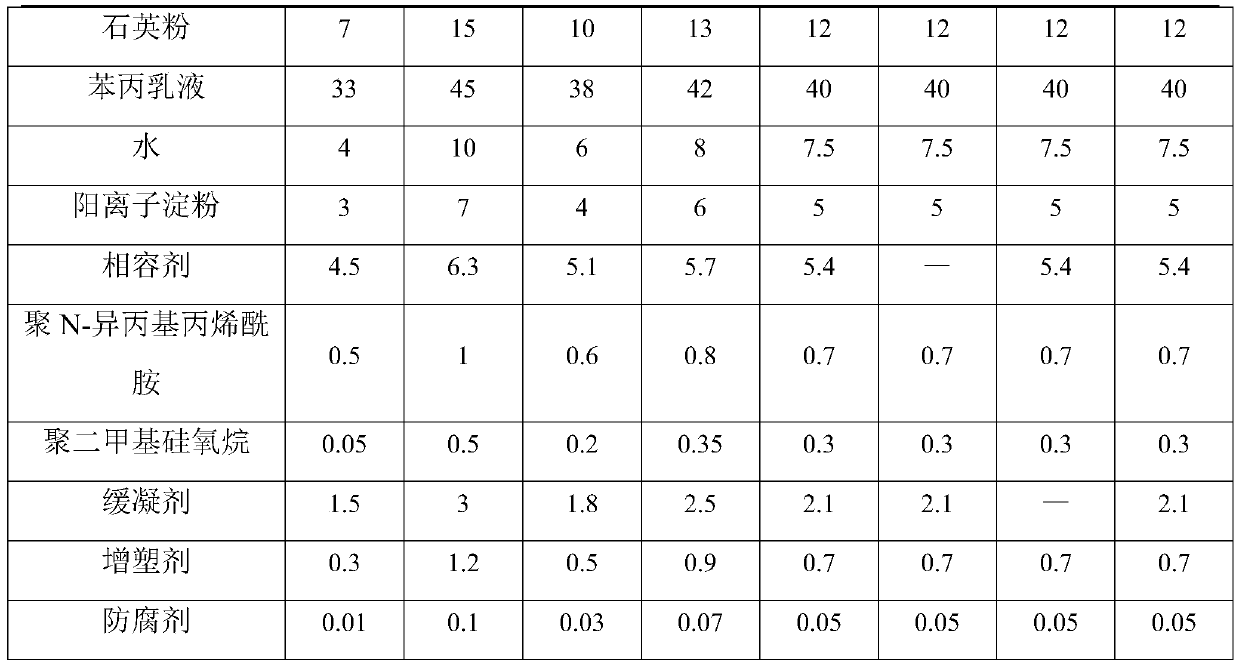

Embodiment 1

[0031] A kind of polymer cement waterproof paint, is made up of the following components by weight:

[0032] 16 parts of cement, 13 parts of heavy calcium powder, 7 parts of quartz powder, 33 parts of styrene-acrylic emulsion, 4 parts of water, 3 parts of cationic starch, 4.5 parts of compatibilizer, 0.5 parts of poly-N-isopropylacrylamide, polydimethyl 0.05 parts of base siloxane, 1.5 parts of retarder, 0.3 parts of plasticizer, 0.01 part of preservative,

[0033] Among them, the cement is 425# white cement, the particle size of heavy calcium powder is 800 mesh, the particle size of quartz powder is 120-400 mesh, and the compatibilizer is bis(lauramide glutamine) sodium lysine, poloxamer and polyethylene glycol. The mass ratio of diol is a mixture of 1:5:3, the average molecular weight of polyethylene glycol is 760-840, and the retarder is a mixture of carboxymethyl chitosan and sucrose stearate with a mass ratio of 2:1. The plasticizer is dioctyl phthalate, the preservative...

Embodiment 2

[0041] A kind of polymer cement waterproof paint, is made up of the following components by weight:

[0042]25 parts of cement, 20 parts of heavy calcium powder, 15 parts of quartz powder, 45 parts of styrene-acrylic emulsion, 10 parts of water, 7 parts of cationic starch, 6.3 parts of compatibilizer, 1 part of poly-N-isopropylacrylamide, polydimethyl 0.5 parts of base siloxane, 3 parts of retarder, 1.2 parts of plasticizer, 0.1 part of preservative,

[0043] Among them, the cement is 425# white cement, the particle size of heavy calcium powder is 800 mesh, the particle size of quartz powder is 120-400 mesh, and the compatibilizer is bis(lauramide glutamine) sodium lysine, poloxamer and polyethylene glycol. The mass ratio of diol is a mixture of 1:5:3, the average molecular weight of polyethylene glycol is 760-840, and the retarder is a mixture of carboxymethyl chitosan and sucrose stearate with a mass ratio of 2:1. The plasticizer is dioctyl phthalate, the preservative is be...

Embodiment 3

[0046] A kind of polymer cement waterproof paint, is made up of the following components by weight:

[0047] 18 parts of cement, 15 parts of heavy calcium powder, 10 parts of quartz powder, 38 parts of styrene-acrylic emulsion, 6 parts of water, 4 parts of cationic starch, 5.1 parts of compatibilizer, 0.6 parts of poly N-isopropylacrylamide, polydimethyl 0.2 parts of base siloxane, 1.8 parts of retarder, 0.5 parts of plasticizer, 0.03 parts of preservative,

[0048] Among them, the cement is 425# white cement, the particle size of heavy calcium powder is 800 mesh, the particle size of quartz powder is 120-400 mesh, and the compatibilizer is bis(lauramide glutamine) sodium lysine, poloxamer and polyethylene glycol. The mass ratio of diol is a mixture of 1:5:3, the average molecular weight of polyethylene glycol is 760-840, and the retarder is a mixture of carboxymethyl chitosan and sucrose stearate with a mass ratio of 2:1. The plasticizer is dioctyl phthalate, the preservativ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com