Novel desulfurization and denitrification activated carbon

A new desulfurization, desulfurization and denitrification technology, applied in inorganic chemistry, gas treatment, membrane technology, etc., can solve the problems of low strength and wear resistance of activated carbon, fewer cycles of use, and low desulfurization and denitrification efficiency, and achieve high pressure resistance and desulfurization speed. Fast, effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

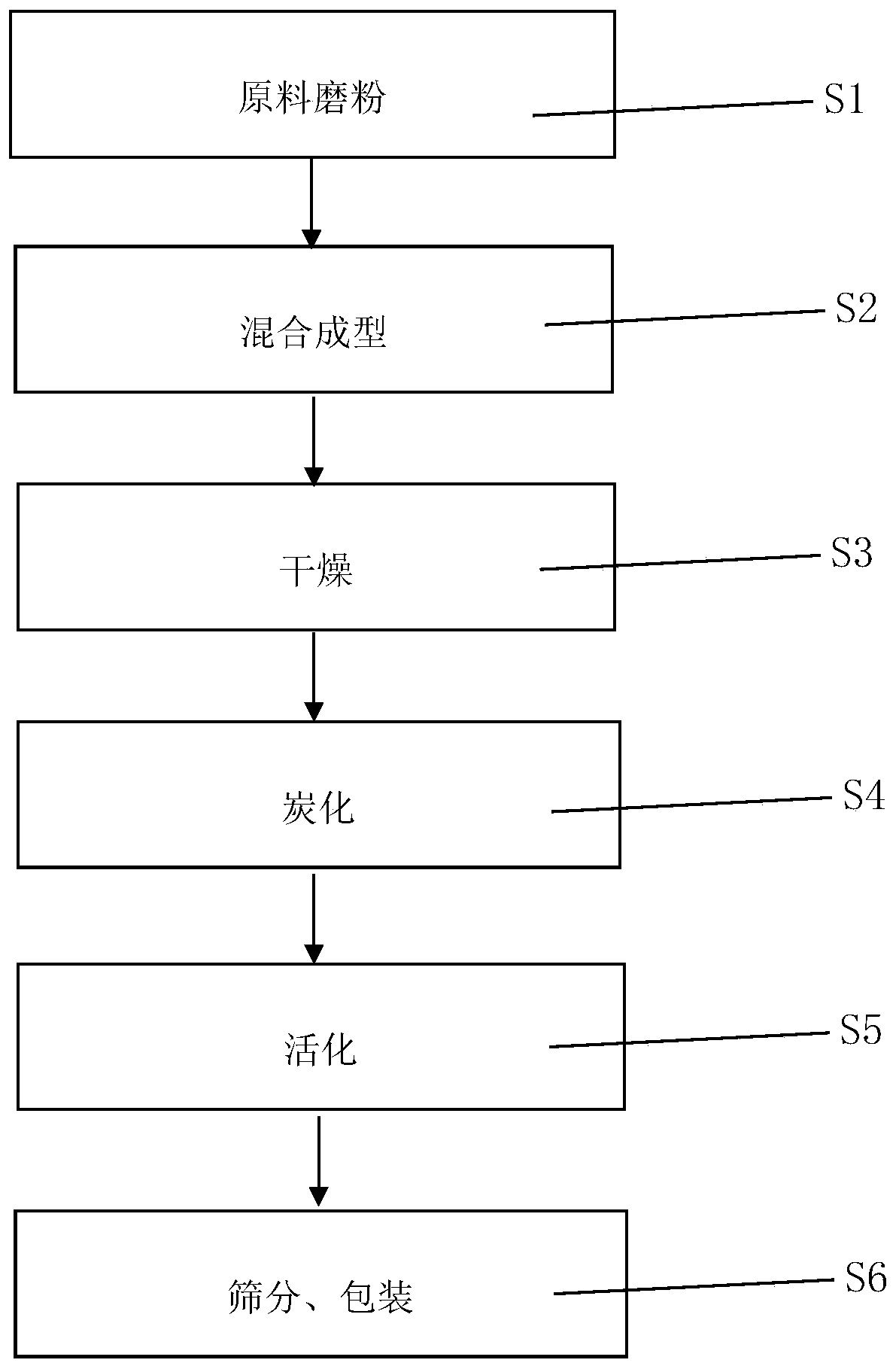

[0027] Such as figure 1 As shown, a new type of desulfurization and denitrification activated carbon is characterized in that the main components of the desulfurization and denitration activated carbon are: coal powder, bentonite, alumina, starch, wherein the ratio of coal powder, bentonite, alumina, starch by weight percentage is: 1:(0.08-0.2):(0.01-0.2):(0.01-0.2). The processing technology of the desulfurization and denitrification activated carbon is as follows: the raw material is pulverized, and the weight ratio of anthracite, bituminous coal (or semi-coal) and coking coal is adjustable at 35:35:30. In the pulverizer, the mixed coal is ground into 200-mesh mixed coal powder with a pass rate of 95% or more, and the coal powder, bentonite, alumina, and starch are 1 by weight: (0.08-0.2): (0.01-0.2): (0.01- 0.2) Add to the mixing pot and mix for 10-20 minutes, add appropriate amount of water and stir for 30 minutes to make the materials fully blend and evenly adhere, and p...

Embodiment 2

[0029] Such as figure 1 As shown, a novel desulfurization and denitrification activated carbon is characterized in that the main components of the desulfurization and denitrification activated carbon are: coal powder, bentonite, alumina, starch, wherein the ratio of coal powder, bentonite, alumina, starch by weight percentage is: 1:(0.08-0.2):(0.01-0.2):(0.01-0.2). The processing technology of the desulfurization and denitrification activated carbon is as follows: the raw material is pulverized, and the weight ratio of anthracite, bituminous coal (or semi-coal) and coking coal is adjustable at 35:35:30. In the pulverizer, the mixed coal is ground into 200-mesh mixed coal powder with a pass rate of 95% or more, and the coal powder, bentonite, alumina, and starch are 1 by weight: (0.08-0.2): (0.01-0.2): (0.01- 0.2) Add to the mixing pot and mix for 10-20 minutes, add appropriate amount of water and stir for 30 minutes to make the materials fully blend and evenly adhere, and produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com