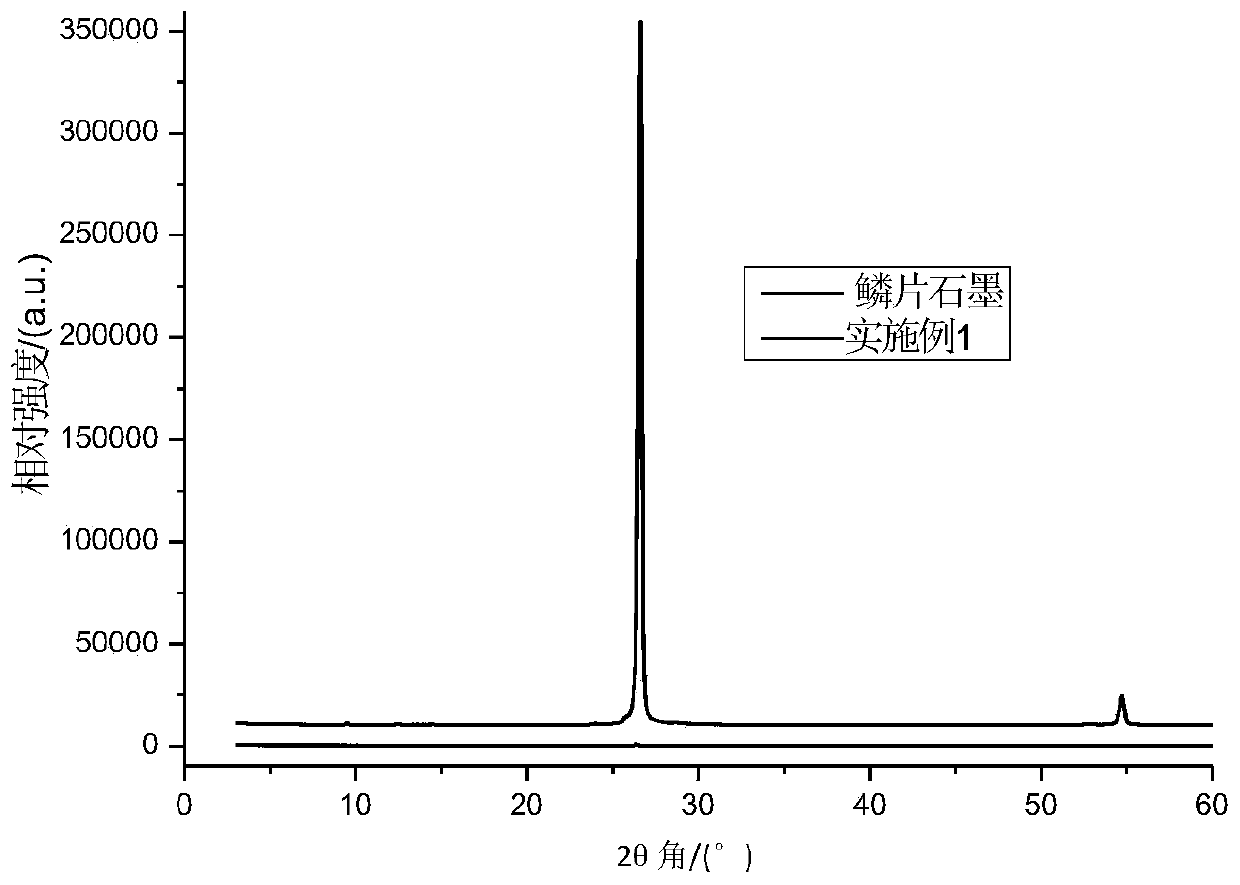

Method for preparing graphene by stripping flake graphite with liquid rubbers

A technology for exfoliating graphene and flake graphite, which is applied in the direction of graphene, single-layer graphene, chemical instruments and methods, etc., can solve the problems of failing to obtain graphene, achieve small footprint, low equipment investment, and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

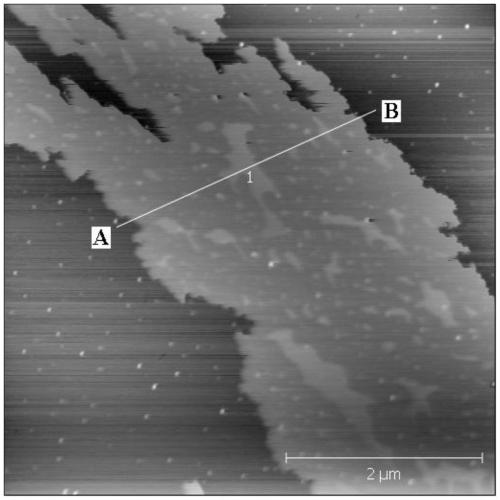

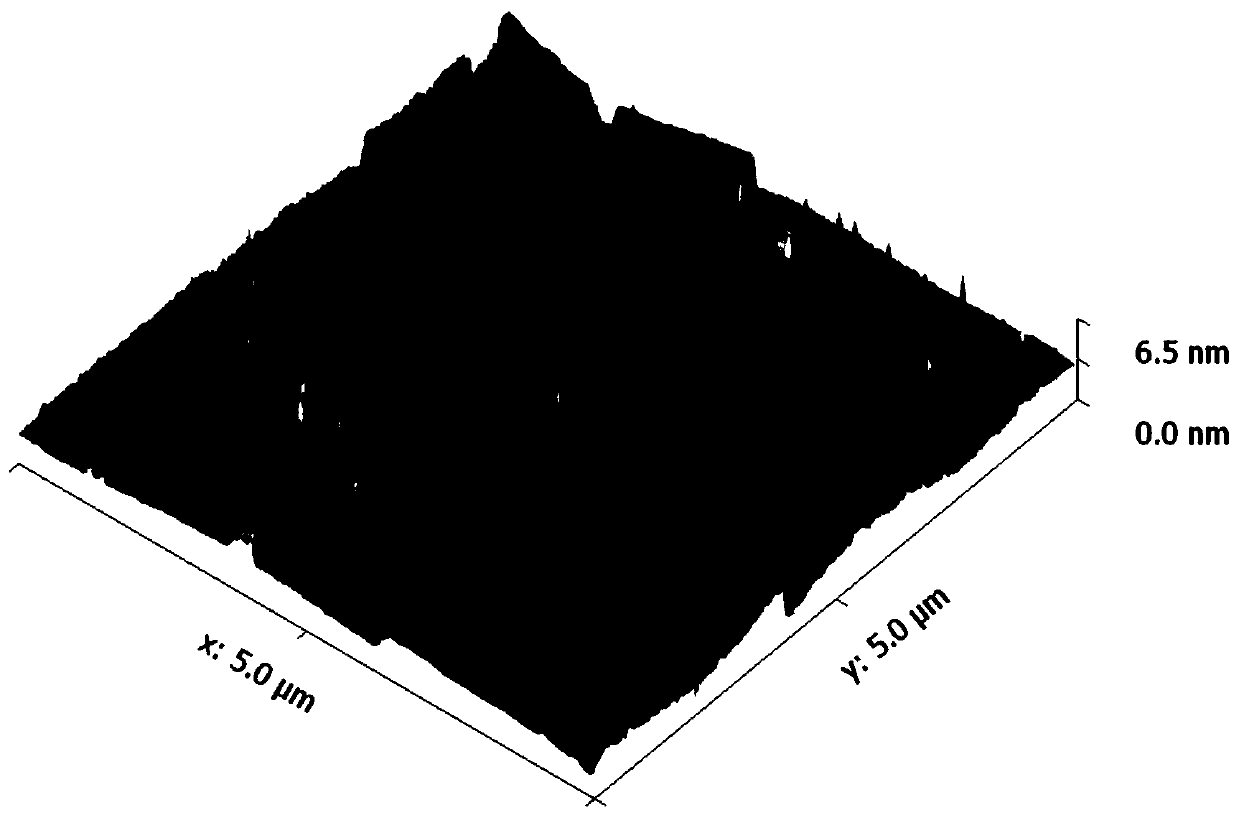

Embodiment 1

[0043] (1) Infiltration of flake graphite

[0044] In the high mixer, add 100g of flake graphite with a particle size of less than 0.5mm, add 10.5ml of a mixture of 10ml of isopropanol and 0.5ml of castor oil, stir for 30 minutes, take it out and dry it, and get the surface wetted by castor oil Modified flake graphite;

[0045] (2) Liquid EPDM rubber and liquid hydrogenated nitrile rubber infiltrate modified flake graphite slurry

[0046] Add 50g of liquid EPDM rubber and 50g of hydrogenated nitrile rubber into the mixing tank, add 50g of castor oil modified flake graphite powder sample, 25mL of banana water and 15ml of engine oil, and stir for 30min at the mixer speed of 800rpm to form a uniform Liquid EPDM rubber and liquid hydrogenated nitrile rubber impregnated flake graphite viscous slurry;

[0047] (3) Preparation of graphene composite latex by exfoliating modified flake graphite from liquid EPDM rubber and liquid hydrogenated nitrile rubber

[0048] The viscous slurr...

Embodiment 2

[0055] (1) Infiltration of flake graphite

[0056] In the high-mixer, add 100g of flake graphite with a particle size of less than 2.0mm, add 25ml of a mixture of 20ml of absolute ethanol and 5ml of rapeseed oil, stir for 5 minutes, take it out and dry it, and obtain a surface moistened with rapeseed oil. Wet modified flake graphite;

[0057] (2) Liquid natural rubber impregnated with modified flake graphite

[0058] Add 100g of liquid natural rubber into the mixing tank, add 1.0g of modified flake graphite powder sample wetted by rapeseed oil, 10mL of kerosene, and stir for 10min at the mixer speed of 100rpm to form a uniform liquid natural rubber infiltrated modified flake Graphite viscous slurry;

[0059] (3) Preparation of graphene composite latex by exfoliating modified flake graphite from liquid natural rubber

[0060] Pour the liquid natural rubber infiltrated modified flake graphite viscous slurry into the feed of the disc refiner in the above step (2), start the eq...

Embodiment 3

[0067] (1) Infiltration of flake graphite

[0068] In the high mixer, add 100g of flake graphite with a particle size of less than 5mm, add 12.5ml of a mixture of 10ml of absolute ethanol and 2.5ml of dioctyl terephthalate, stir for 20min, take it out and dry it, and get the surface Flake graphite modified with dioctyl terephthalate;

[0069] (2) Liquid neoprene infiltration modified flake graphite slurry

[0070] 100g liquid neoprene is added in the mixing tank, add modified flake graphite powder sample 70g, 25mL machine oil, under the condition of mixer rotating speed 500rpm, stir 20min, form the viscous slurry that uniform liquid neoprene soaks flake graphite;( 3) Preparation of graphene latex by exfoliating flake graphite from liquid neoprene rubber

[0071] Pour the liquid neoprene infiltrated modified flake graphite viscous slurry into the hopper of the colloid mill in the above step (2), start the equipment, adjust the rotating speed at 1000rpm, and peel off 100min in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com