Method of utilizing salt ions to pretreat rice bran to process fresh wet coarse rice noodles

A salt ion and pretreatment technology, which is applied in food science and other fields, can solve the problems of easy oxidative rancidity, poor sensory texture quality of fresh and wet brown rice noodles, and short shelf life, so as to inhibit spoilage bacteria, reduce damaged starch content, and extend shelf life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

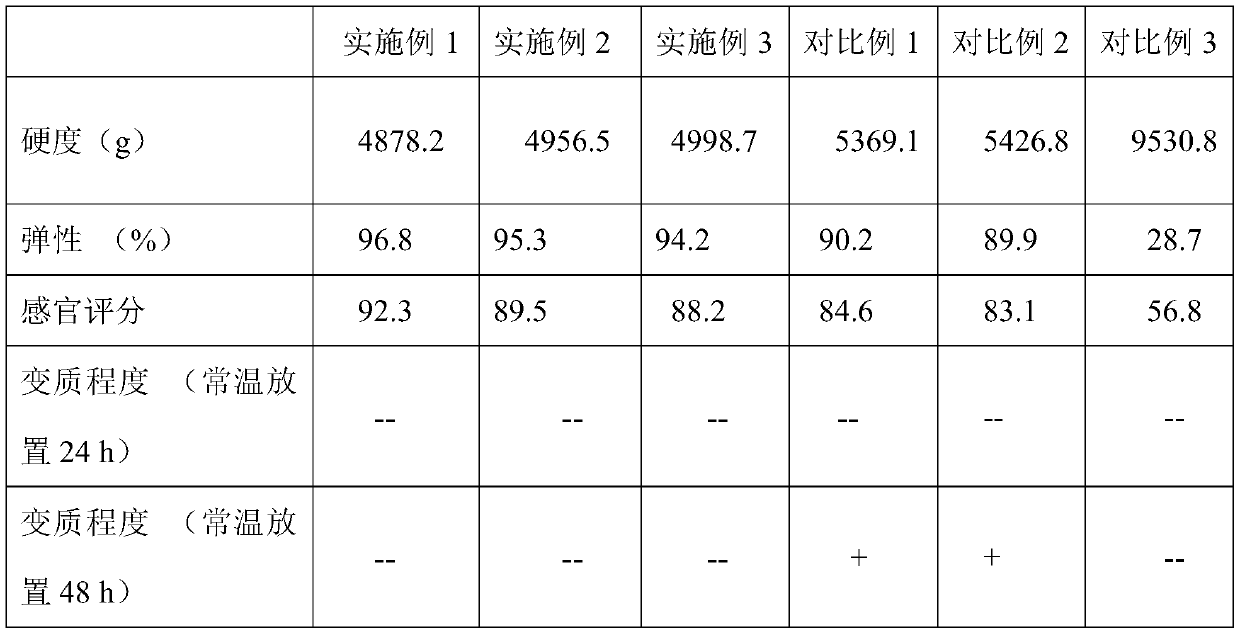

Examples

Embodiment 1

[0040] (1) select 20kg indica brown rice for use, remove debris such as floating ash and mixed gravel, wash with pure clear water, and grind to obtain rice bran and white rice;

[0041] (2) After soaking the white rice, crush it until the particle fineness is between 30-70 μm, and control the damaged starch content of the white rice flour below 12%;

[0042] (3) Mix the obtained rice bran with a 50mM salt ion solution at a material-to-liquid ratio of 1:10, soak for 1 hour, heat at 120°C for 10 minutes, and after cooling, grind until the particle size of the rice bran in the slurry is 30-70 μm between;

[0043] (4) Mix the rice bran powder slurry and white rice flour evenly, adjust the moisture content to 30%, and obtain the brown rice flour slurry;

[0044] (5) aging at 90°C for 60 minutes;

[0045] (6) Put the cured brown rice dough into a wire extruder to extrude;

[0046] (7) Aging for 24 hours at 25°C;

[0047] (8) Cooking at 85°C for 5 minutes;

[0048] (9) Packing a...

Embodiment 2

[0050] (1) select 20kg indica brown rice for use, remove debris such as floating ash and mixed gravel, wash with pure clear water, and grind to obtain rice bran and white rice;

[0051] (2) After soaking the white rice, crush it until the particle fineness is between 30-70 μm, and control the damaged starch content of the white rice flour below 12%;

[0052] (3) Mix the obtained rice bran with a 250mM salt ion solution at a material-to-liquid ratio of 1:5, soak for 4 hours, heat at 100°C for 30 minutes, and after cooling, grind until the particle size of the rice bran in the slurry is 30-70 μm between;

[0053] (4) Mix the rice bran powder slurry and white rice flour evenly, adjust the moisture content to 36%, and obtain the brown rice flour slurry;

[0054] (5) aging at 120°C for 1 min;

[0055] (6) Put the cured brown rice dough into a wire extruder to extrude;

[0056] (7) Aging for 14 hours at 37°C;

[0057] (8) Cook at 95°C for 2.5 minutes;

[0058] (9) Packing after...

Embodiment 3

[0060] (1) select 20kg indica brown rice for use, remove debris such as floating ash and mixed gravel, wash with pure clear water, and grind to obtain rice bran and white rice;

[0061] (2) After soaking the white rice, crush it until the particle fineness is between 30-70 μm, and control the damaged starch content of the white rice flour below 12%;

[0062] (3) Mix the obtained rice bran with a 500mM salt ion solution at a material-to-liquid ratio of 1:3, soak for 8 hours, heat at 80°C for 60 minutes, and after cooling, grind until the particle size of the rice bran in the slurry is 30-70 μm between;

[0063] (4) Mix the rice bran powder slurry and white rice flour evenly, adjust the water content to 45%, and obtain the brown rice flour slurry;

[0064] (5) aging at 100°C for 15 minutes;

[0065] (6) Put the cured brown rice dough into a wire extruder to extrude;

[0066] (7) Aging for 4 hours at 50°C;

[0067] (8) Cooking at 100°C for 0.5min;

[0068] (9) Packing after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com