Graphite composite negative electrode material, preparation method thereof and battery

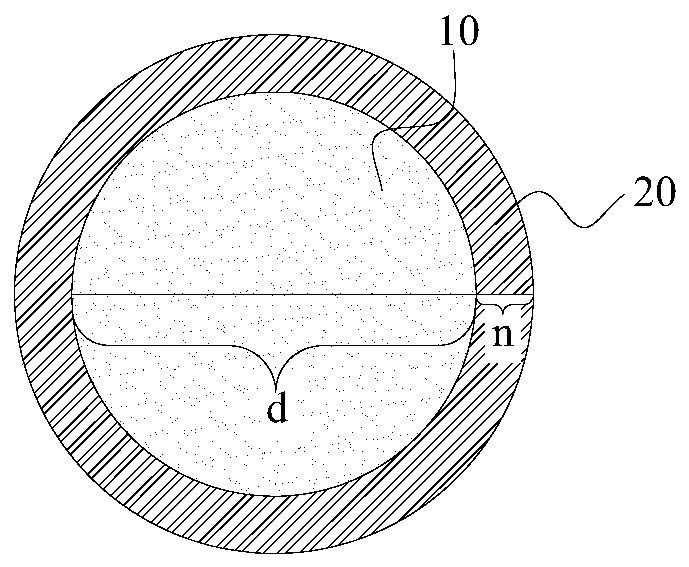

A negative electrode material and composite material technology, which is applied in the field of graphite composite negative electrode materials and its preparation, can solve the problems of poor fast charging performance, poor cycle performance and safety performance, and low charge and discharge rate of lithium-ion batteries, so as to improve fast charging performance and The effect of safety performance, low cost and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

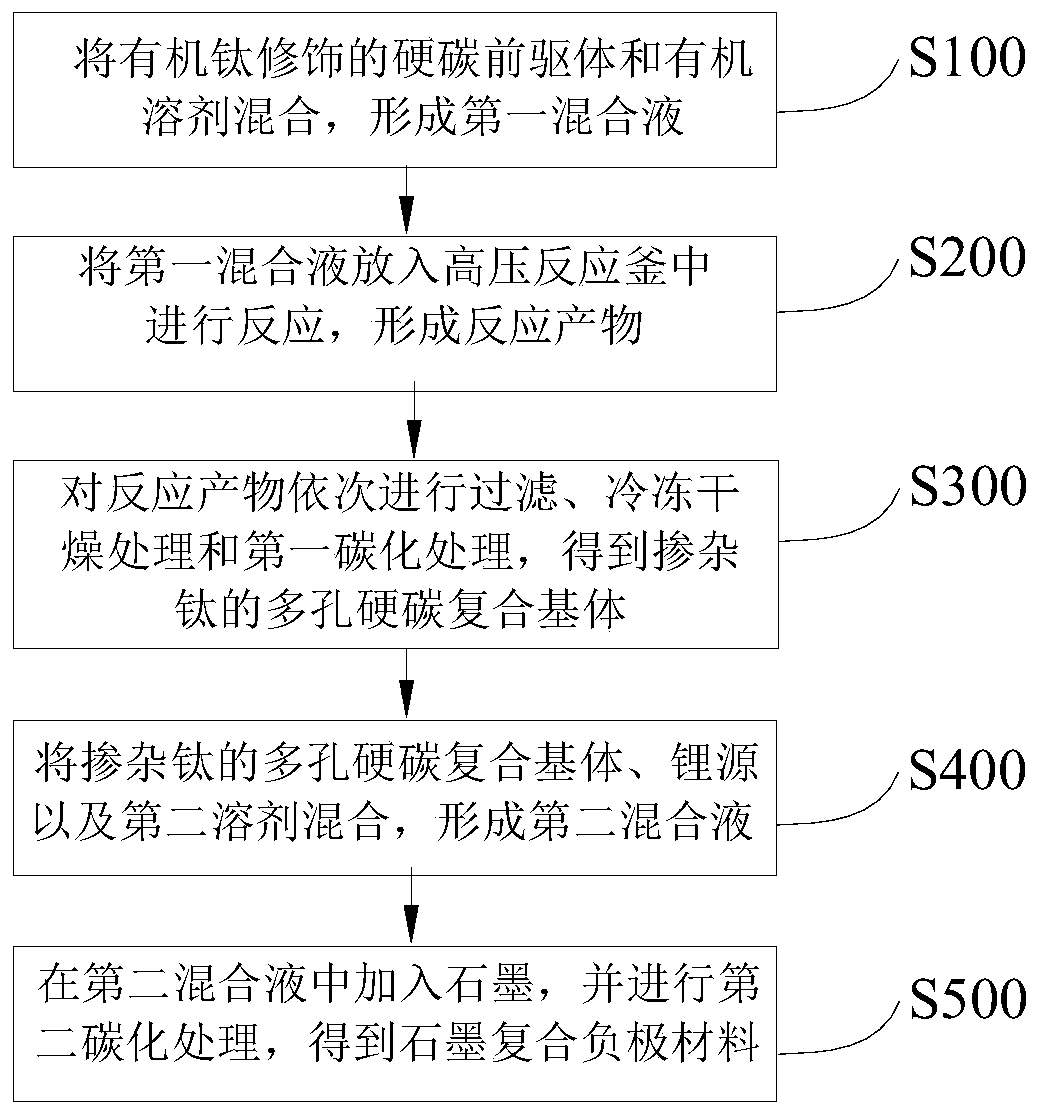

[0051] Embodiment 1: Preparation of graphite composite negative electrode material A

[0052] (1) Add 100g of organic titanium epoxy resin to 1000mL of toluene to configure a homogeneous solution with a mass concentration of 10wt%, that is, the first mixed solution;

[0053] (2) Add 3g of graphene to the first mixed solution, stir evenly, transfer to the autoclave, and react for 2h at a temperature of 100°C and a pressure of 2Mpa to form a reaction product;

[0054] (3) filter the reaction product formed in the previous step, freeze-dry at low temperature, and heat up to 500° C. for carbonization for 6 h under an argon atmosphere to obtain a titanium-doped porous composite hard carbon matrix A;

[0055] (4) 3g lithium carbonate is added to the deionized water of 37.5g, and configuration concentration is the lithium carbonate brine solution of 8wt%;

[0056] (5) Add 20 g of the titanium-doped porous composite hard carbon substrate A prepared in step (3) to the lithium carbonat...

Embodiment 2

[0058] Embodiment 2: Preparation of graphite composite negative electrode material B

[0059] (1) Add 100g of organic titanium epoxy resin to 2000mL of toluene, and configure it into a homogeneous solution with a mass concentration of 5wt%, that is, the first mixed solution;

[0060] (2) Add 1g of graphene to the first mixed solution, stir evenly, transfer to the autoclave, and react for 2h at a temperature of 100°C and a pressure of 2Mpa to form a reaction product;

[0061] (3) filter the reaction product formed in the previous step, freeze-dry at low temperature, and heat up to 500° C. for carbonization for 6 h under an argon atmosphere to obtain a titanium-doped porous composite hard carbon matrix B;

[0062] (4) 1g of lithium zirconate is added to 20g of deionized water, and the configuration concentration is an aqueous solution of lithium carbonate salt of 5wt%;

[0063] (5) Add 30 g of the titanium-doped porous hard carbon composite matrix B prepared in step (3) to the ...

Embodiment 3

[0065] Embodiment 3: Preparation of graphite composite negative electrode material C

[0066] (1) Add 100g organic titanium epoxy resin to 500g cyclohexanone, and configure it into a homogeneous solution with a concentration of 20wt%, that is, the first mixed solution;

[0067] (2) Add 5g graphene in the first mixed solution, after stirring evenly, transfer to the autoclave, and at a temperature of 100°C and a pressure of 2Mpa, react for 2h to form a reaction product;

[0068] (3) filter the reaction product formed in the previous step, freeze-dry at low temperature, and heat up to 500° C. for carbonization for 6 h under an argon atmosphere to obtain a titanium-doped porous composite hard carbon matrix C;

[0069] (4) Add 5g of lithium zirconate to 50g of deionized water, and configure a lithium zirconate salt solution with a concentration of 10wt%;

[0070] (5) Add 30 g of titanium-doped porous hard carbon composite matrix C prepared in step (3) to the aqueous solution of li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com