A kind of NdFeB magnet manufacturing method

A manufacturing method and NdFeB technology, applied in inductor/transformer/magnet manufacturing, electrical components, circuits, etc., can solve the problem that magnet fragments cannot be completely smelted, and achieve simple implementation, avoid secondary rework, and uniform heating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

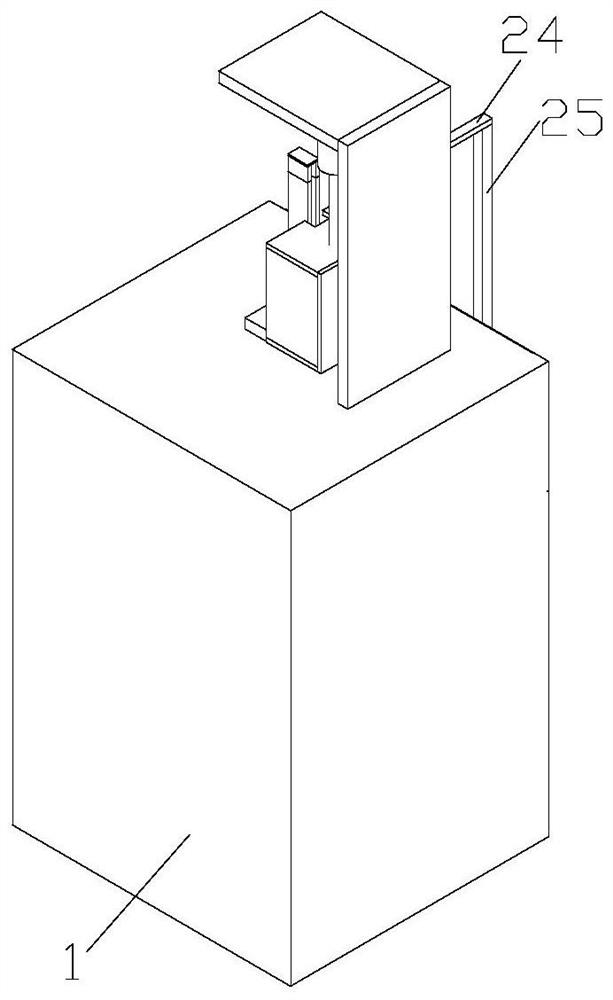

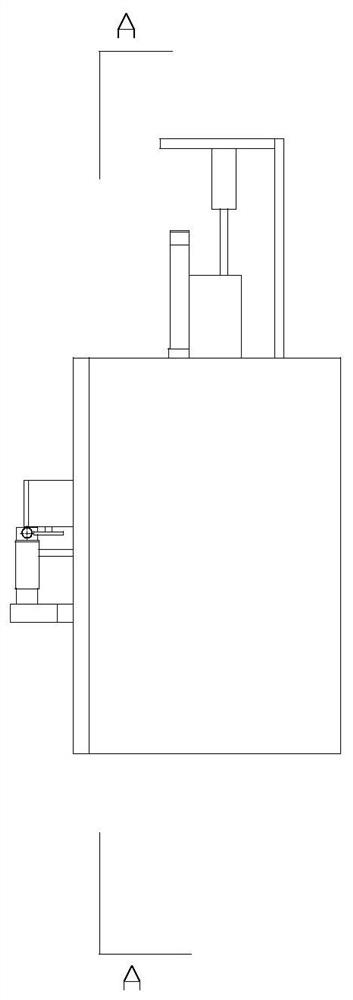

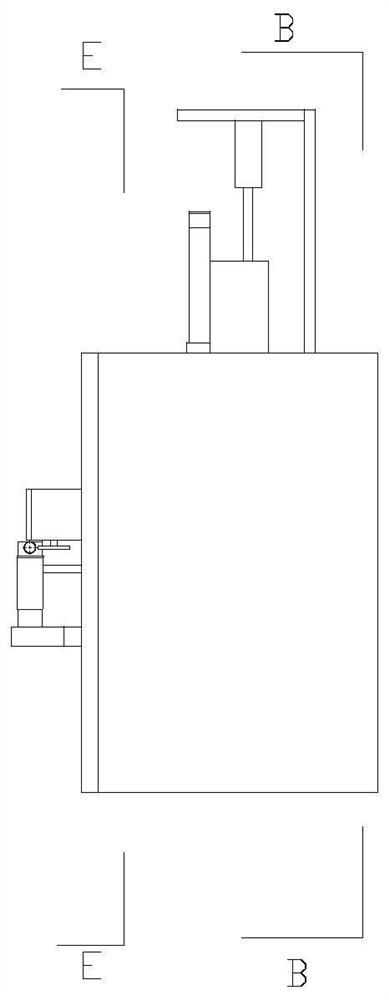

[0039] In order to achieve the above object, the present invention adopts the following technical solutions: a method for manufacturing an NdFeB magnet, comprising the following steps:

[0040] a. Raw material preparation and pretreatment: Weighing, crushing, cutting and derusting the magnets by using steel bar cutting machine and drum polishing machine;

[0041] b. Melting: Use a vacuum melting furnace to melt the pretreated magnets to make NdFeB alloys;

[0042] c. Hydrogen explosion: use a vacuum hydrogen treatment furnace to carry out hydrogen explosion on the smelted NdFeB alloy;

[0043] d. Powder making: use a magnet crusher to crush the NdFeB alloy fragments after hydrogen explosion into powder;

[0044]e. Molding orientation: use a magnetic field press and an isostatic press to shape the powder;

[0045] f. Sintering: use a vacuum sintering furnace to sinter the formed semi-finished product;

[0046] g. Machining: use a grinding machine to machine the sintered NdFe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com