A kind of high-strength plastic nano/submicron crystal cold-rolled 304 stainless steel strip and its preparation method

A 304 stainless steel and nanotechnology, which is applied in the field of high-strength plastic nano/submicron crystal cold-rolled 304 stainless steel strip and its preparation, can solve the problems of increasing the risk of delayed cracking of materials, affecting the corrosion resistance of parts, affecting the forming of parts, etc. , to avoid the increase of intergranular corrosion tendency, reduce the risk of delayed cracking, and save energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

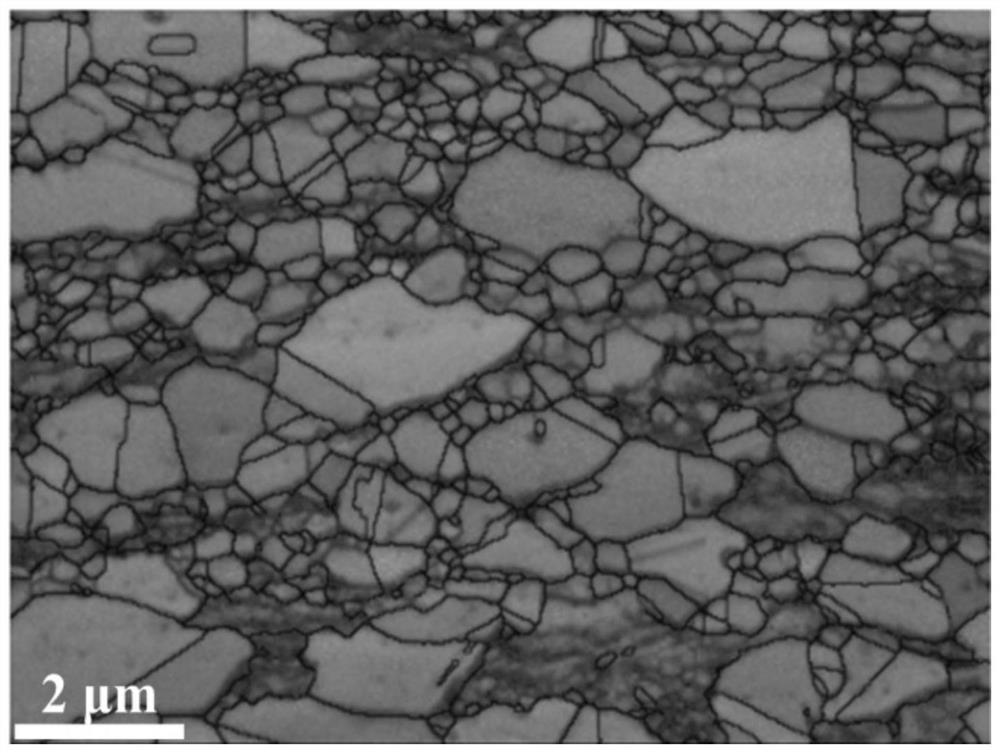

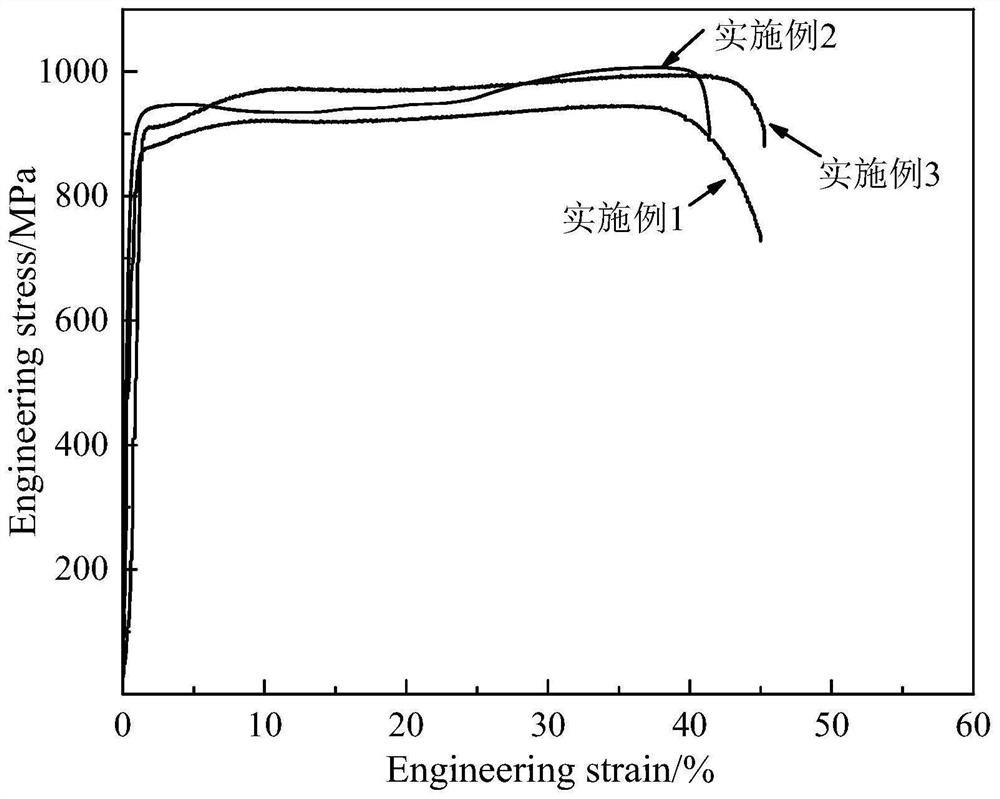

Embodiment 1

[0031] The composition of the 304 stainless steel blank in this example is C: 0.055%, Si: 0.40%, Mn: 1.63%, Cr: 17.30%, Ni: 8.45%, Mo: 0.12%, Nb: 0.04%, V: 0.08%, The balance is Fe and other unavoidable impurities, and the total weight percentage of each component is 100%.

[0032] A kind of preparation method of high-strength plastic nano / submicron crystal cold-rolled 304 stainless steel strip of the present invention, comprises the following steps:

[0033] Step 1, forging and hot rolling:

[0034] Place the forged billet with a thickness of 50mm in a heating furnace and heat it to 1250°C with the furnace and hold it for 2h, then roll it on a hot rolling mill for 5 passes to form a hot-rolled sheet with a thickness of 4.5mm, and then roll it at a temperature of 30°C / s Cool quickly with water to room temperature. The starting rolling temperature is 1200°C, the final rolling temperature is 1050°C, and the total hot rolling reduction rate is 91%;

[0035] Step 2, solution tr...

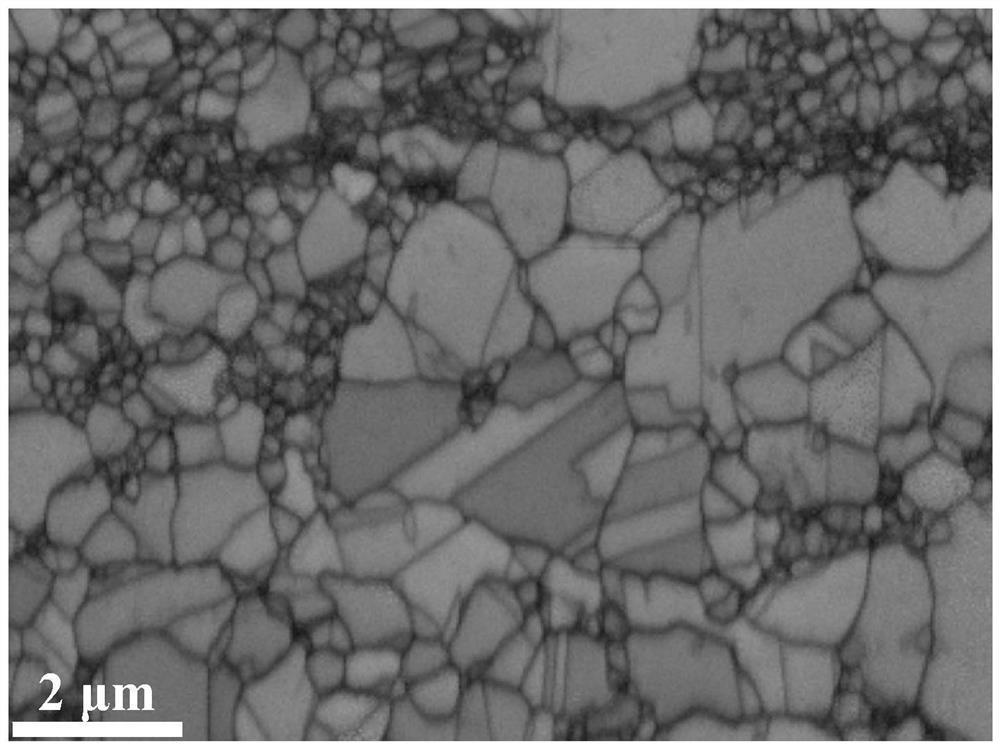

Embodiment 2

[0042] The composition of the 304 stainless steel blank in this example is C: 0.075%, Si: 0.28%, Mn: 1.58%, Cr: 17.4%, Ni: 8.2%, Mo: 0.10%, Nb: 0.04%, V: 0.07%, The balance is Fe and other unavoidable impurities, and the total weight percentage of each component is 100%.

[0043]A kind of preparation method of high-strength plastic nano / submicron crystal cold-rolled 304 stainless steel strip of the present invention, comprises the following steps:

[0044] Step 1, forging and hot rolling:

[0045] The forged billet with a thickness of 60mm was placed in a heating furnace and heated to 1200°C with the furnace and held for 3 hours, and then rolled into a hot-rolled sheet with a thickness of 6mm on a hot rolling mill for 7 passes, and then cold rolled at 40°C / s. Quickly cool to room temperature. The rolling start temperature is 1160°C, the final rolling temperature is 1000°C, and the total hot rolling reduction is about 90%;

[0046] Step 2, solution treatment and cold rolling...

Embodiment 3

[0053] The composition of the 304 stainless steel blank in this example is C: 0.062%, Si: 0.38%, Mn: 1.57%, Cr: 17.2%, Ni: 8.5%, Mo: 0.09%, Nb: 0.01%, V: 0.02%, The balance is Fe and other unavoidable impurities, and the total weight percentage of each component is 100%.

[0054] A kind of preparation method of high-strength plastic nano / submicron crystal cold-rolled 304 stainless steel strip of the present invention, comprises the following steps:

[0055] Step 1, forging and hot rolling:

[0056] The forged billet with a thickness of 60 mm was placed in a heating furnace and heated to 1180 °C with the furnace and kept for 2 hours, and then rolled into a hot-rolled sheet with a thickness of 5 mm on a hot rolling mill for 7 passes, and then cold rolled at 35 °C / s. Quickly cool to room temperature. The starting rolling temperature is 1150°C, the final rolling temperature is 1010°C, and the total hot rolling reduction is about 92%;

[0057] Step 2, solution treatment and cold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com