CHO cell culture method in bioreactor

A bioreactor, cell culture technology, applied in the field of CHO cell culture in bioreactors, can solve the problems of no obvious improvement in antibody yield and quality, poor versatility, etc., to achieve wide applicability, reduce costs, and shorten the cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

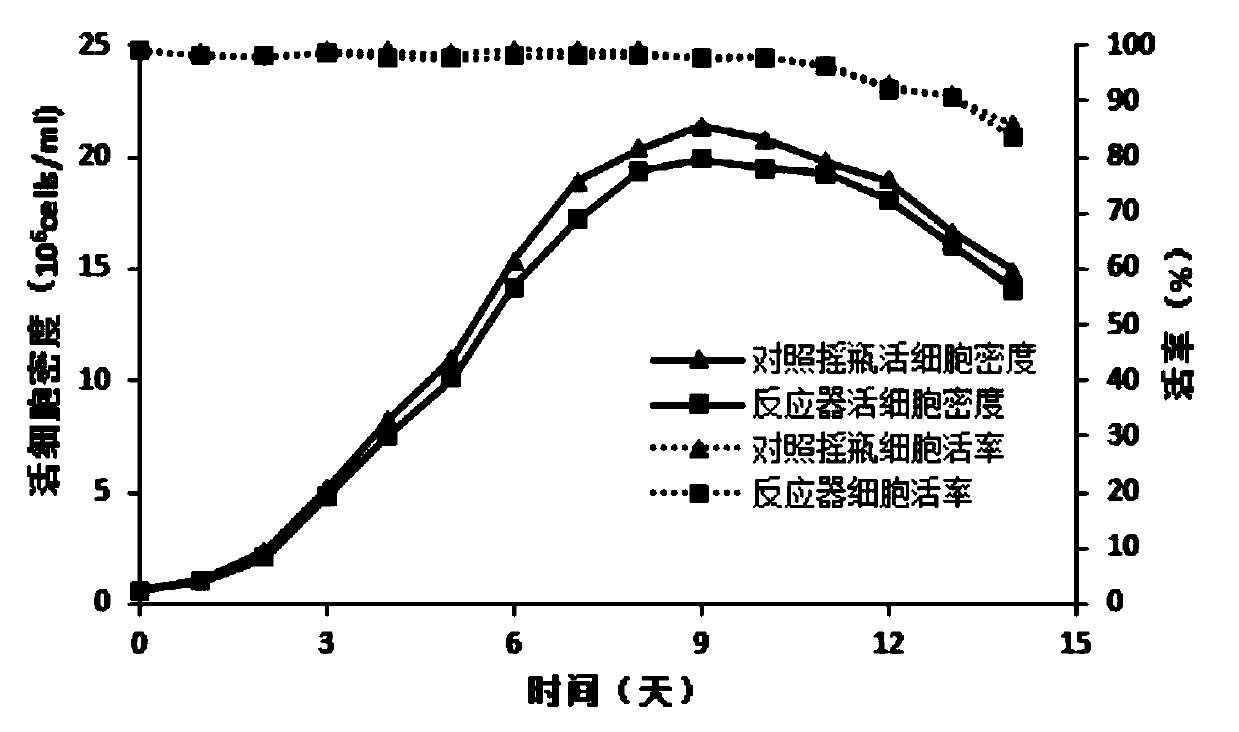

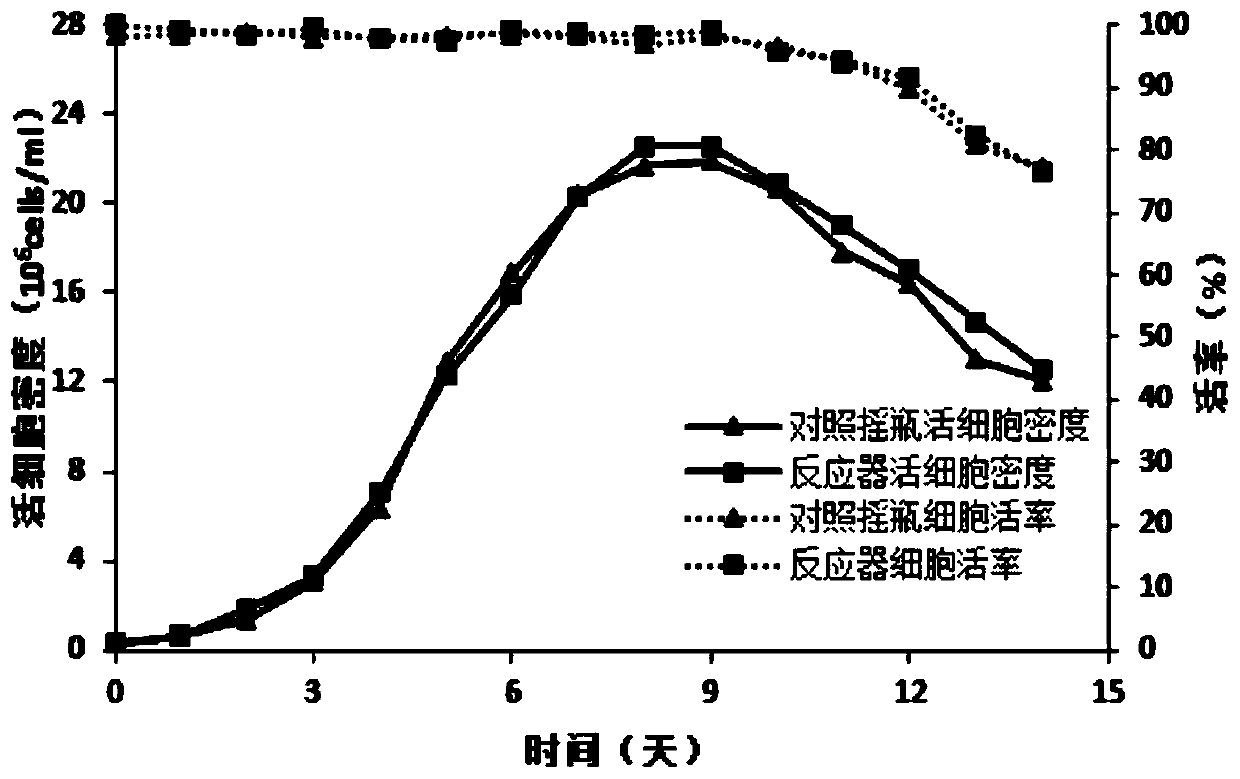

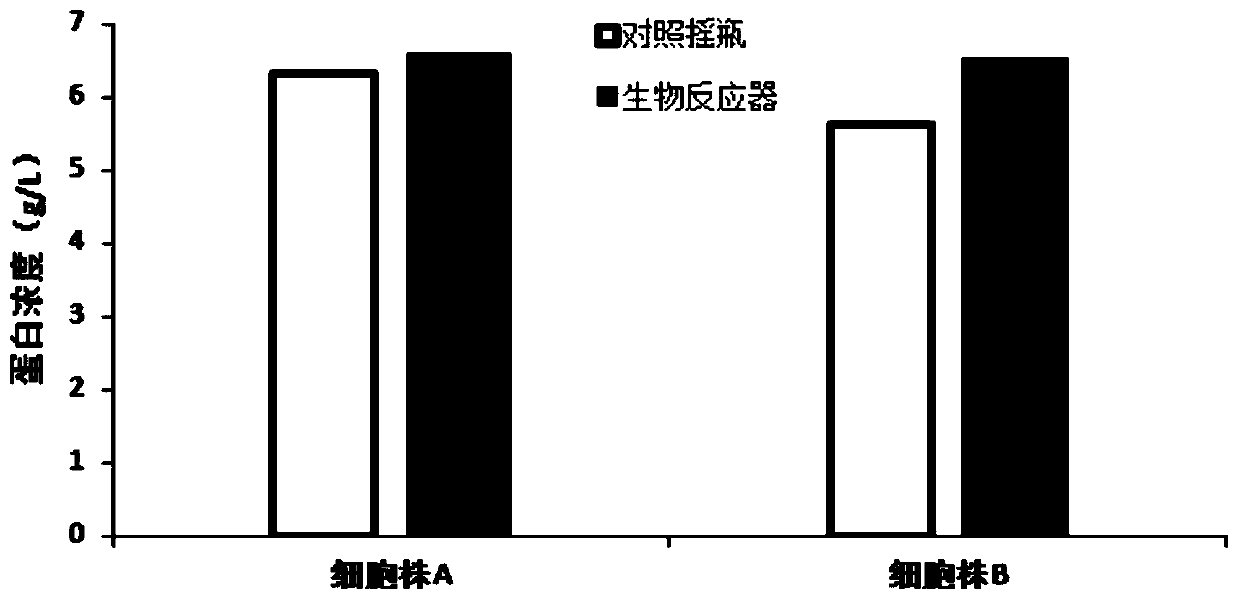

Embodiment 1

[0039] The CHO cell culture process of the present embodiment is as follows:

[0040] (1) Insert the basal medium into the reactor, inoculate two GS-CHO antibody expressing cell lines A and B respectively, the inoculation density is 0.6106cells / ml, set the dissolved oxygen to 40%, the temperature is controlled at 37C, the rotation speed is 140rpm, and CO2 and NaHCO3 solution to adjust the pH to 7.0-7.3;

[0041] (2) After culturing for a certain period of time (3rd day), control the pH range to 6.8 to 7.0, and adjust the rotation speed to 220rpm on the 6th day;

[0042] (3) From the 4th day, feed once every 2 days, the volume of the feed medium added each time is 5% of the initial culture volume, and stop feeding when the cell viability drops below 80%;

[0043] (4) The basic medium is Dynamis, and the fed-batch medium is EfficientFeedTM C+;

[0044] (5) Shake flask culture is a control group, and the shake flask culture conditions are: temperature control 37°C, CO Concentra...

Embodiment 2

[0049] This example adopts the same method as Example 1 for culturing, wherein the basal medium is ActiPro, the fed-batch medium is Cell Boost 7a / 7b, and the inoculated cell line is GS-CHO antibody-expressing cell line C. This example also uses Shake flask culture was used as control group.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com