Fabric pressure sensing array, manufacturing method thereof and pressure distribution detection system

A sensing array and pressure technology, which is applied in fabrics, textiles and papermaking, and the measurement of the properties and forces of piezoelectric resistance materials, etc., can solve the problems of fabric pressure sensing array crosstalk, difficult large-scale processing, poor mechanical properties, etc. problem, achieve the effect of reducing crosstalk effect, simple manufacturing method, and short processing flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

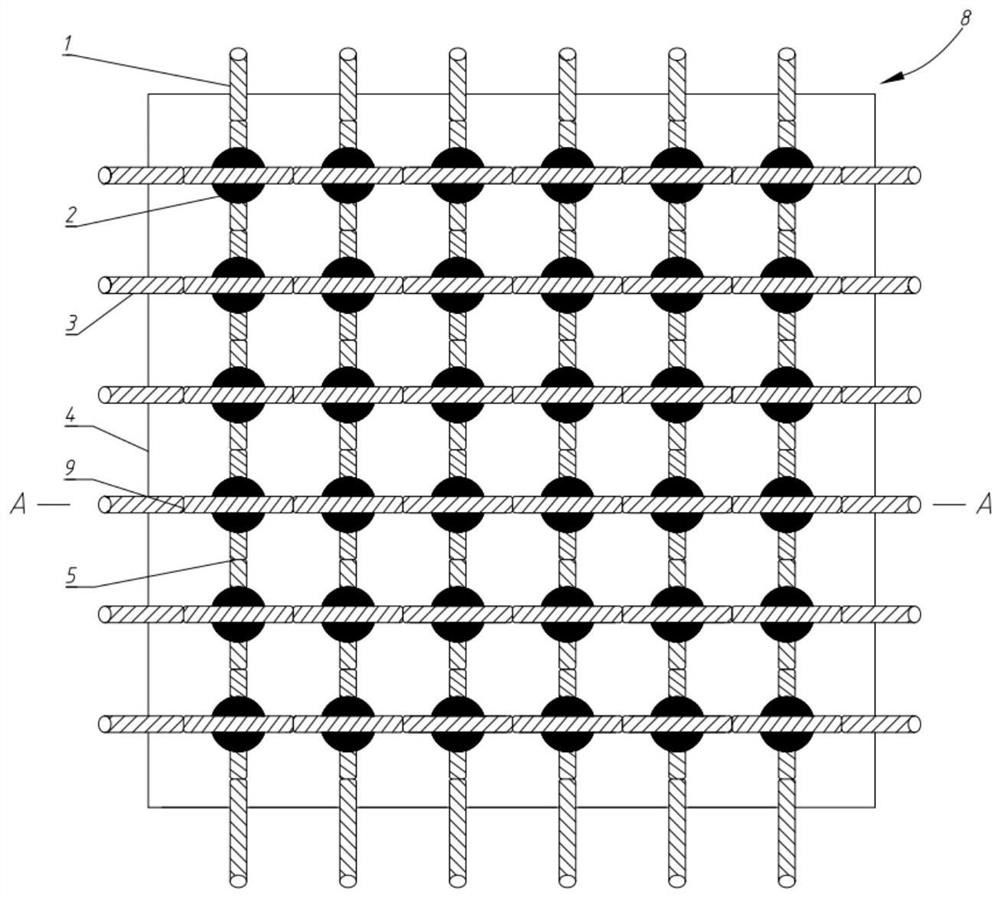

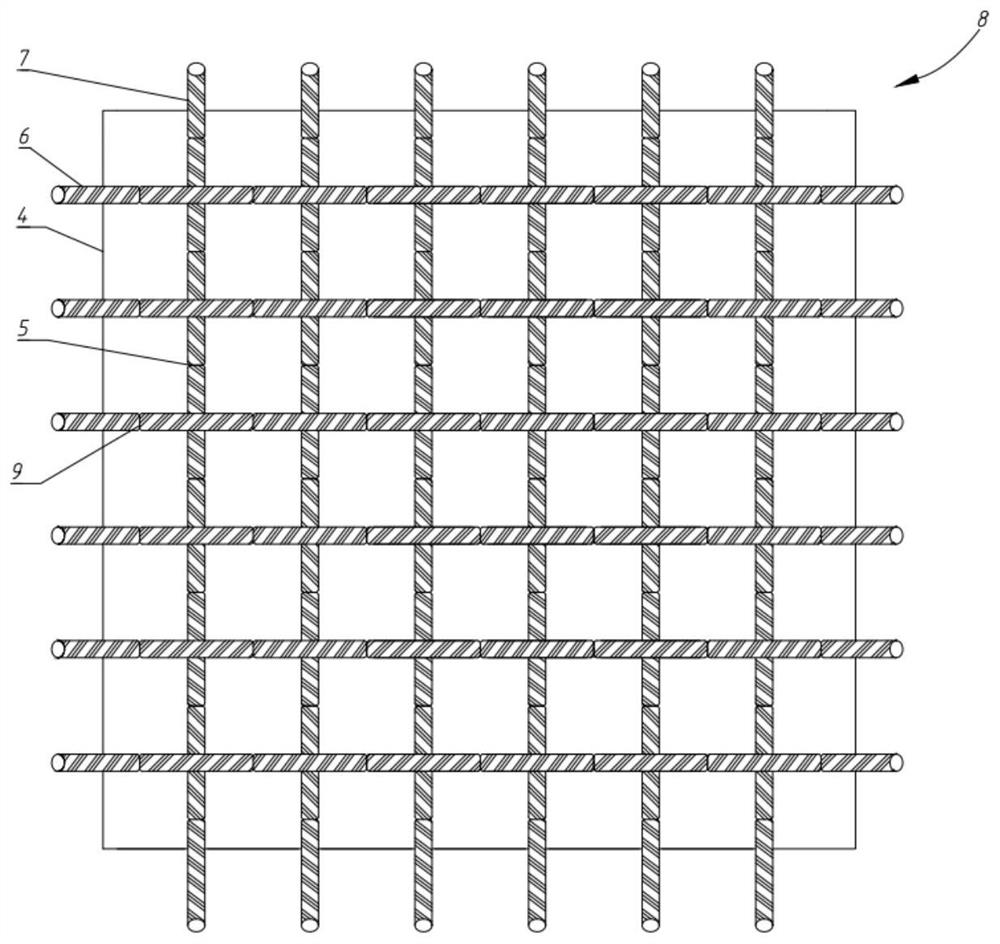

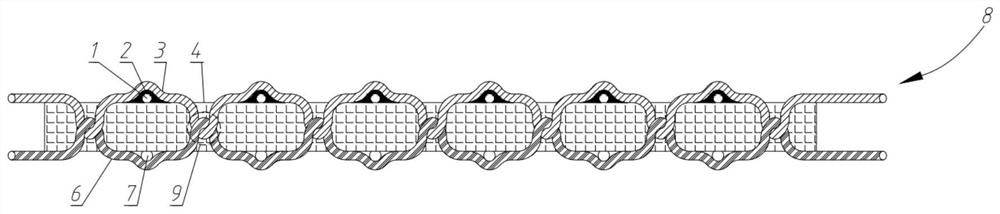

[0033] Figure 1-3 A schematic structural diagram of the fabric pressure sensing array 8 of this embodiment is shown. like figure 1 and figure 2 As shown, the fabric pressure sensing array 8 is composed of the base fabric 4, the first conductive yarn 1, the second conductive yarn 3, the first non-conductive yarn 7, the second non-conductive yarn 6 and the pressure sensing unit 2 . In the present embodiment, base fabric 4 has a grammage of 98.8g / m 2, Pure polyester plain woven fabric with a warp density of 150 threads / 5cm and a weft density of 150 threads / 5cm. The first conductive yarn 1 and the second conductive yarn 3 are located on the front side of the base fabric 4 , and the first non-conductive yarn 7 and the second non-conductive yarn 6 are located on the reverse side of the base fabric 4 . In this embodiment, there are 6 first conductive yarns 1 in total, arranged along the warp direction of the base fabric 4 , and adjacent conductive yarns are evenly arranged at ...

Embodiment 2

[0045] like Figure 7 As shown, a fabric pressure sensor array 8 provided in this embodiment is connected with a signal processing and control module 10 and a data storage and display module 11 to form a schematic diagram of a pressure distribution measurement system 12 . The difference between this embodiment and Embodiment 1 is that the data storage and display module 11 is a mobile terminal (which may be a mobile phone, a tablet computer, etc.). Wireless communication is performed between the wireless communication module 20 on the signal processing and control module 10 and the mobile terminal. The signal processing and control module 10 transmits the measured pressure value acting on the fabric pressure sensor array 8 to the mobile terminal through the wireless communication, and the mobile terminal stores the pressure value in the form of data, and stores the pressure value as form to display.

[0046] It can be seen that the fabric pressure sensing array of the presen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| resistance per length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com