Preparation method of mesoporous titanium silicalite molecular sieve nanoparticles

A titanium-silicon molecular sieve and nanoparticle technology, applied in molecular sieve catalysts, chemical instruments and methods, crystalline aluminosilicate zeolites, etc., can solve the problem that the catalytic performance cannot be well exerted, and the contact frequency between the reactant and the reactive center is low. , limit a wide range of applications, etc., to achieve the effects of excellent catalytic performance, inhibition of possible side reactions, and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

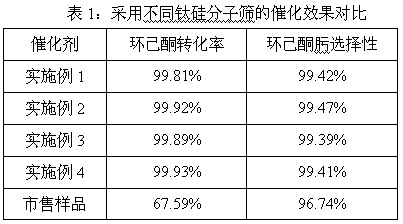

Examples

Embodiment 1

[0026] A preparation method of mesoporous titanium silicon molecular sieve nanoparticles, according to the following steps:

[0027] 1. Weigh tetraethyl orthosilicate, polyvinyl alcohol, deionized water, ammonia water with a mass concentration of 25%, tetrabutyl titanate, hydrogen peroxide and polyquaternium-6, wherein, ethyl orthosilicate The molar ratio with polyvinyl alcohol is 1:0.1, the molar ratio of ethyl orthosilicate and deionized water is 1:50, the mass ratio of ethyl orthosilicate and ammonia water with a mass concentration of 25% is 1:1, The molar ratio of ethyl orthosilicate to tetrabutyl titanate is 1:0.03, the molar ratio of ethyl orthosilicate to hydrogen peroxide is 1:2, and the mass ratio of polyquaternium-6 to polyvinyl alcohol is 1:0.05;

[0028] 2. Add the polyvinyl alcohol, polyquaternium-6 and ammoniacal liquor with a mass concentration of 25% into deionized water successively in step 1. After mixing evenly, a mixed solution is obtained, and then under ...

Embodiment 2

[0033] A preparation method of mesoporous titanium silicon molecular sieve nanoparticles, according to the following steps:

[0034] 1. Weigh tetraethyl orthosilicate, polyvinyl alcohol, deionized water, ammonia water and tetrabutyl titanate, hydrogen peroxide and polyquaternium-6 with a mass concentration of 25%, wherein tetraethyl orthosilicate and The molar ratio of polyvinyl alcohol is 1:0.18, the molar ratio of ethyl orthosilicate to deionized water is 1:65, the mass ratio of ethyl orthosilicate to ammonia water with a mass concentration of 25% is 1:1, and The molar ratio of ethyl silicate to tetrabutyl titanate is 1:0.025, the molar ratio of tetraethyl orthosilicate to hydrogen peroxide is 1:2, and the mass ratio of polyquaternium-6 to polyvinyl alcohol is 1 : 4.5;

[0035] 2. Add the polyvinyl alcohol, polyquaternium-6 and ammoniacal liquor with a mass concentration of 25% into deionized water successively in step 1. After mixing evenly, a mixed solution is obtained, a...

Embodiment 3

[0040] A preparation method of mesoporous titanium silicon molecular sieve nanoparticles, according to the following steps:

[0041] 1. Weigh tetraethyl orthosilicate, polyvinyl alcohol, deionized water, ammonia water and tetrabutyl titanate, hydrogen peroxide and polyquaternium-6 with a mass concentration of 25%, wherein tetraethyl orthosilicate and The molar ratio of polyvinyl alcohol is 1:0.15, the molar ratio of ethyl orthosilicate to deionized water is 1:60, the mass ratio of ethyl orthosilicate to ammonia water with a mass concentration of 25% is 1:1.2, and The molar ratio of ethyl silicate to tetrabutyl titanate is 1:0.01, the molar ratio of tetraethyl orthosilicate to hydrogen peroxide is 1:4, and the mass ratio of polyquaternium-6 to polyvinyl alcohol is 1 : 2;

[0042] 2. Add the polyvinyl alcohol, polyquaternium-6 and ammoniacal liquor with a mass concentration of 25% into deionized water successively in step 1. After mixing evenly, a mixed solution is obtained, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com