Method for preparing medicine albumin nanoparticles

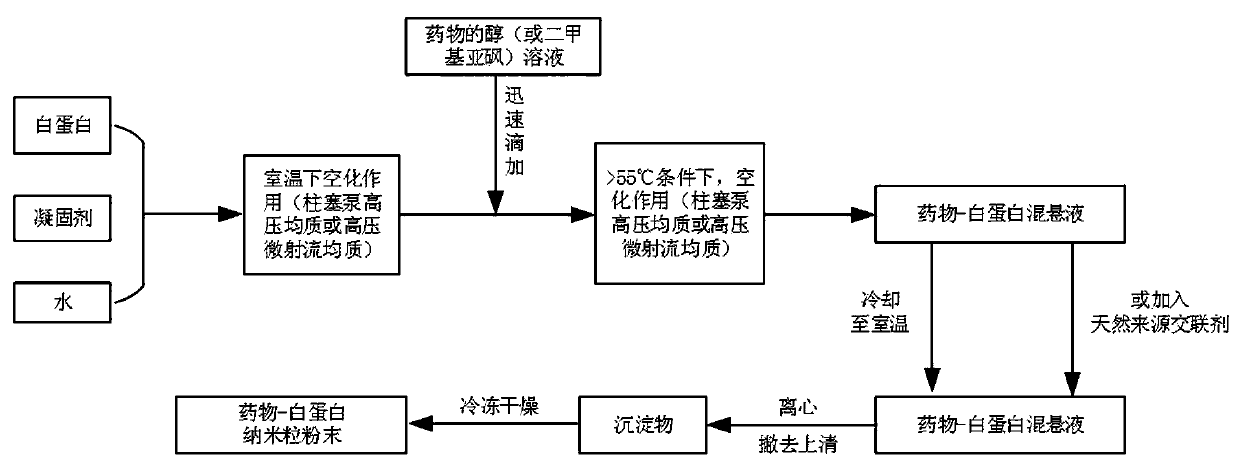

An albumin nanoparticle and a technology for preparing medicine, which are applied in the field of preparing medicine albumin nanoparticle, can solve the problems of low solubility, difficult vanillin, long time consumption and the like, and achieve the effects of fewer process steps, simple operation and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Paclitaxel 0.4g

[0050] Bovine Serum Albumin 8g

[0052] Preparation Process:

[0053] (1) Add paclitaxel 0.4g into 10ml of absolute ethanol to dissolve.

[0054] (2) Dissolve 8g of bovine serum albumin and 0.08g of calcium chloride in 400ml of water for injection.

[0055] (3) At room temperature, add the solution in step 2 into the plunger pump high-pressure homogenizer cup, and homogenize at 15MPa. At the same time, the ethanol solution of the drug in step 1 was quickly dripped into the homogenizer material cup by using a peristaltic pump, and the dripping speed was 10ml / min. After all the drug solution is dropped in, increase the homogenization pressure to 50MPa, and at the same time, increase the homogenization temperature to 65°C (heated by hot water circulation). After 3 cycles of homogenization at 50MPa, increase the pressure to 80MPa and perform 5 cycles of homogenization. The suspension was cooled to room temperature, pla...

Embodiment 2

[0058] Paclitaxel 0.15g

[0059] Human Serum Albumin 1.5g

[0060] Calcium acetate 0.15g

[0061] Tannic acid 0.3g

[0062] Preparation Process:

[0063] (1) Add 0.15g of paclitaxel into 3ml of absolute ethanol to dissolve.

[0064] (2) Dissolve 1.5g of human serum albumin and 0.15g of calcium acetate in 30ml of water for injection.

[0065] (3) At room temperature, put the solution in step 2 into the cup of a high-pressure micro-fluidic homogenizer, and homogenize at 15MPa. At the same time, the drug ethanol solution in step 1 was quickly dripped into the material cup by using a peristaltic pump, and the dripping speed was 10ml / min. After all the drug solution is dripped in, increase the homogenization pressure to 50MPa, and use the temperature control system to increase the temperature of the high-pressure homogenization to 70°C. After 3 cycles of 50MPa homogenization, increase the pressure to 100MPa, and homogenize for 3 times. cycle. Naturally cool the suspension to...

Embodiment 3

[0068] Doxorubicin 0.5g

[0069] Bovine Serum Albumin 10g

[0070] Calcium Lactate 0.5g

[0071] Preparation Process:

[0072] (1) Add 0.5 g of doxorubicin to 20 ml of dimethyl sulfoxide to dissolve.

[0073] (2) Add 10g of bovine serum albumin and 0.5g of calcium lactate into 200ml of water for injection to dissolve.

[0074] (3) At room temperature, add the solution in step 2 into the plunger pump high-pressure homogenizer cup, and homogenize at 15MPa. At the same time, the doxorubicin dimethyl sulfoxide solution in step 1 was quickly dropped into the homogenizer material cup by using a peristaltic pump, and the dropping speed was 10ml / min. After all the drug solution is dropped in, increase the homogenization pressure to 120MPa, and at the same time, increase the homogenization temperature to 70°C (heated by hot water circulation). Homogenize for 3 cycles. The suspension was cooled to room temperature, placed in a high-speed centrifuge, and centrifuged at 10,000 r / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

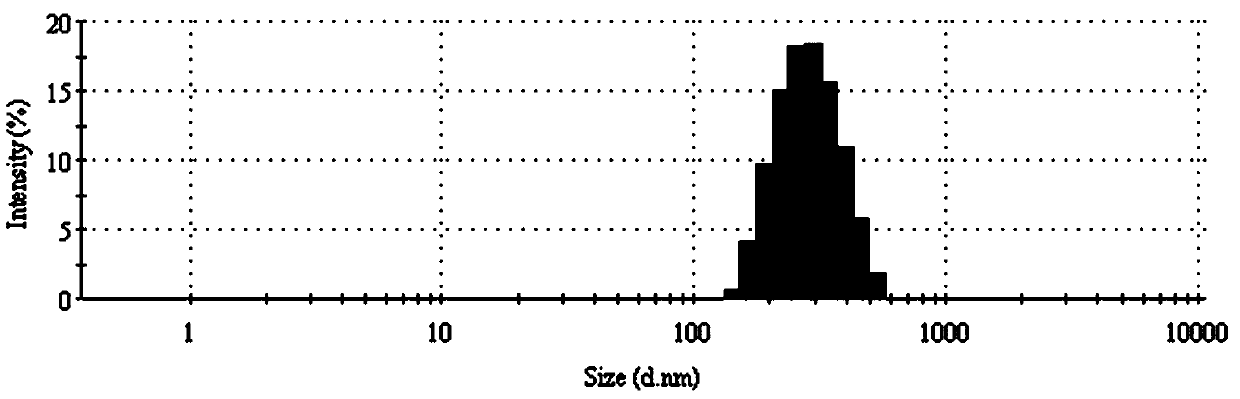

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com