Device for drying lithium iodide and preparing method of lithium iodide

A lithium iodide and drying technology, applied in lithium halide, heating device, drying solid materials and other directions, can solve the problems of large organic reagents, difficult operation, cost, etc., to reduce the content of free iodine, the preparation process is convenient and fast, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

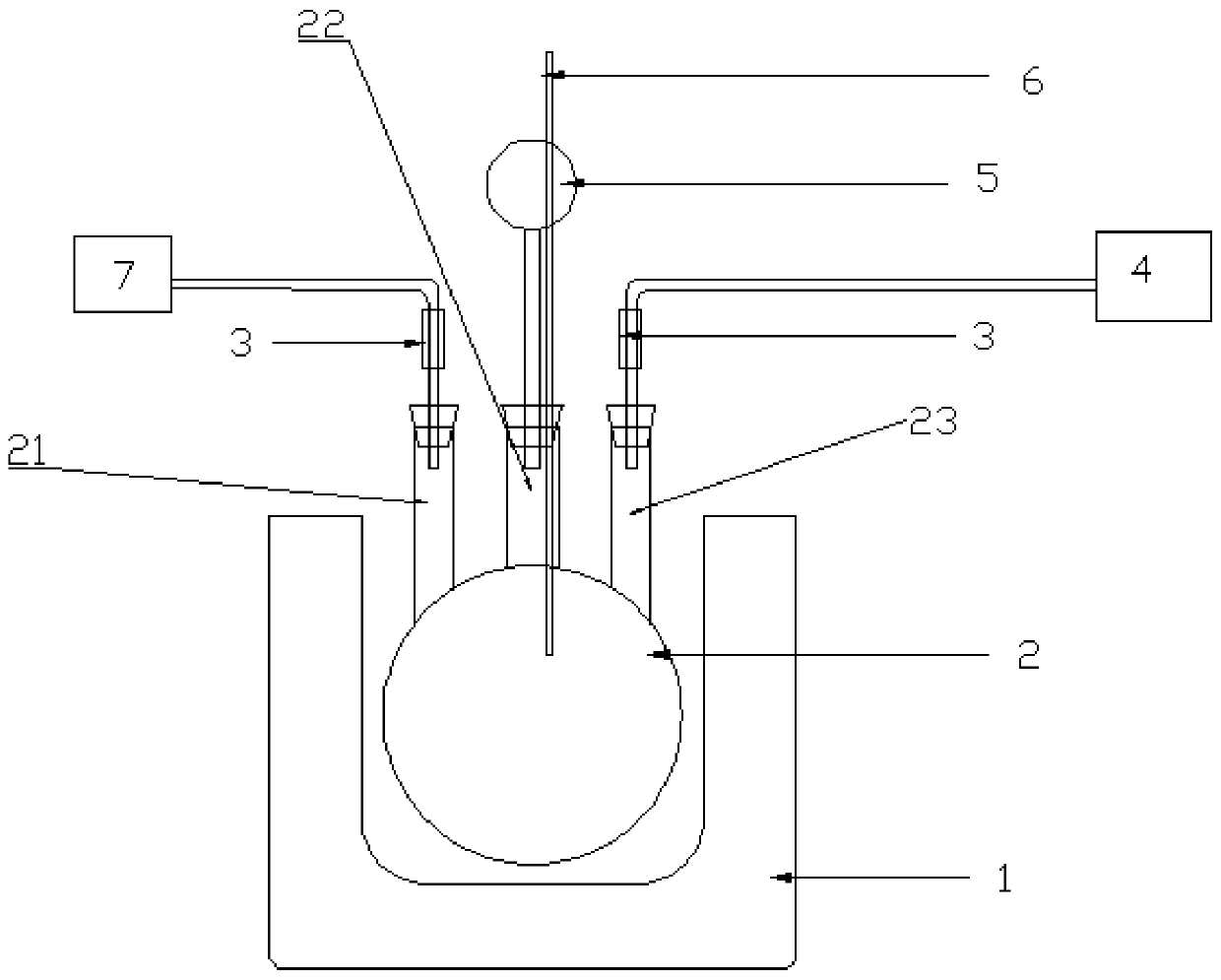

[0031] Such as figure 1 As shown, a device for drying anhydrous lithium iodide in this embodiment includes a heating mantle 1, a flask 2, a vacuum pump 4, an argon gas bottle 7 and a vacuum pressure gauge 5, and the flask 2 is arranged inside the heating mantle 1 , the flask 2 is a three-necked flask, and the three ports are respectively the first interface 21, the second interface 22 and the third interface 23, and the first interface 21, the second interface 22 and the third interface 23 pass through the pipe respectively. Road and argon cylinder 7, vacuum pressure gauge 5 and vacuum pump 4 sealing connection.

[0032] In a further solution, the second interface 22 is also connected with a device 6 for measuring the internal temperature of the flask. The first port 21 and the third port 23 are respectively connected with joints for controlling the connection or disconnection of the flask 2 with the argon bottle 7 and the vacuum pump 4 . The joint is a quick joint 3, one si...

Embodiment 2

[0035] Present embodiment is a kind of method utilizing the device of embodiment 1 to prepare anhydrous lithium iodide, comprises the steps:

[0036] (1) Put 500g of lithium iodide trihydrate in a 5000ml three-neck flask, connect the devices according to the above-mentioned device, vacuumize the flask for 8 minutes, and slowly raise the temperature to 78°C through the electric heating mantle for 2.5 hours while evacuating the vacuum, and then dry it for 2.5 hours. The rate is controlled at 0.5°C / min, and argon is passed every 30 minutes during the drying process;

[0037] (2) Continue to dry in vacuum, then raise the temperature to 240°C and then dry for 10 hours. The heating rate is controlled at 0.5°C / min. During the drying process, the argon gas is passed every 30 minutes, the electric heating mantle is turned off, the heating is stopped, and the vacuum is continued. Wait for the flask to cool down to room temperature naturally, inject argon, close the spring valve on the f...

Embodiment 3

[0039] Present embodiment is a kind of method utilizing the device of embodiment 1 to prepare anhydrous lithium iodide, comprises the steps:

[0040] (1) Put 500g of lithium iodide trihydrate in a 5000ml three-necked flask, connect the devices according to the described device, vacuumize the flask for 10min, and slowly raise the temperature to 80°C through the electric heating mantle to dry for 2h while pumping the vacuum, the heating rate Control at 0.5°C / min, pass argon every 30 minutes during the drying process;

[0041] (2) Continue vacuum drying, then raise the temperature to 250°C and then dry for 8 hours. The heating rate is controlled at 0.5°C / min. During the drying process, the argon gas is passed every 30 minutes, the electric heating mantle is turned off, the heating is stopped, and the vacuum is continued. Wait for the flask to cool down to room temperature naturally, inject argon, close the spring valve on the flask, remove the flask, move it into a glove box, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com