Strain, and construction method and application thereof

A construction method and strain technology, applied in the field of strains, can solve the problems of random mutation of strains, increased production costs, side effects of product synthesis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

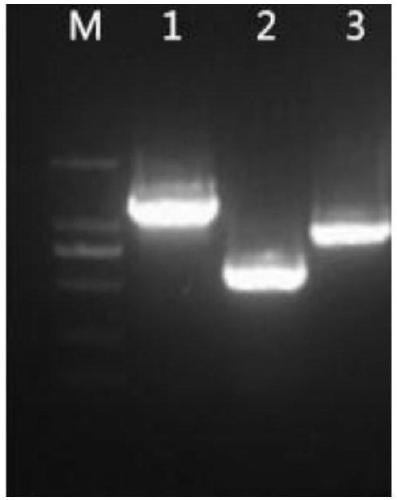

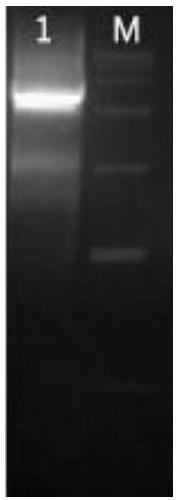

[0092] Embodiment 1: Construction of knockout plasmid pLO3-pigA:

[0093] The genome of MHZ-20000 was extracted using an extraction kit. The upstream and downstream homology arms of pigA used the MHZ-20000 genome as a template, and primers pigA-1SF / pigA-1SR and pigA-1XF / pigA–1XR and PrimeSTAR DNA polymerase ( TakaraBio, Tokyo, Japan) amplification. The upstream and downstream DNA fragments were connected by overlap PCR, the product was detected by electrophoresis, and the target gene band was purified and recovered by a gel extraction kit to obtain a recombinant fragment. The recombinant fragment and pLO3 plasmid were simultaneously digested with restriction enzymes SacI and XbaI, 37°C, 90min, and the digested fragment was purified and recovered by PCR using a kit, and the recovered products of the two were digested with T4DNA ligase at 16°C After connecting overnight, the recombinant plasmid pLO3-pigA was obtained, and the recombinant plasmid was transferred into E.coli S17 ...

Embodiment 2

[0094] Embodiment 2: Construction of the knockout plasmid pLO3-vgb:

[0095] The vgb gene was derived from the E.coli S17 / pBBR-vgb preserved in our laboratory. The pBBR-vgb plasmid was extracted using an extraction kit, and the plasmid was used as a template for PCR to amplify using primers Pvgb-F / Pvgb-R and PrimeSTAR DNA polymerase. Amplify the vgb gene, detect the product by electrophoresis, and purify and recover the target gene band through the gel recovery kit to obtain the target gene vgb. The genome of MHZ-20000 was extracted using an extraction kit, and the upstream and downstream homology arms of pigA were amplified using the MHZ-20000 genome as a template, using primers pigA-2SF / pigA-2SR and pigA-2XF / pigA–2XR and PrimeSTAR DNA polymerase, respectively . Connect the upstream and downstream DNA fragments with the vgb gene by overlapping PCR, the connection method is pigA upstream homology arm-vgb gene-pigA downstream homology arm, the product is detected by electropho...

Embodiment 3

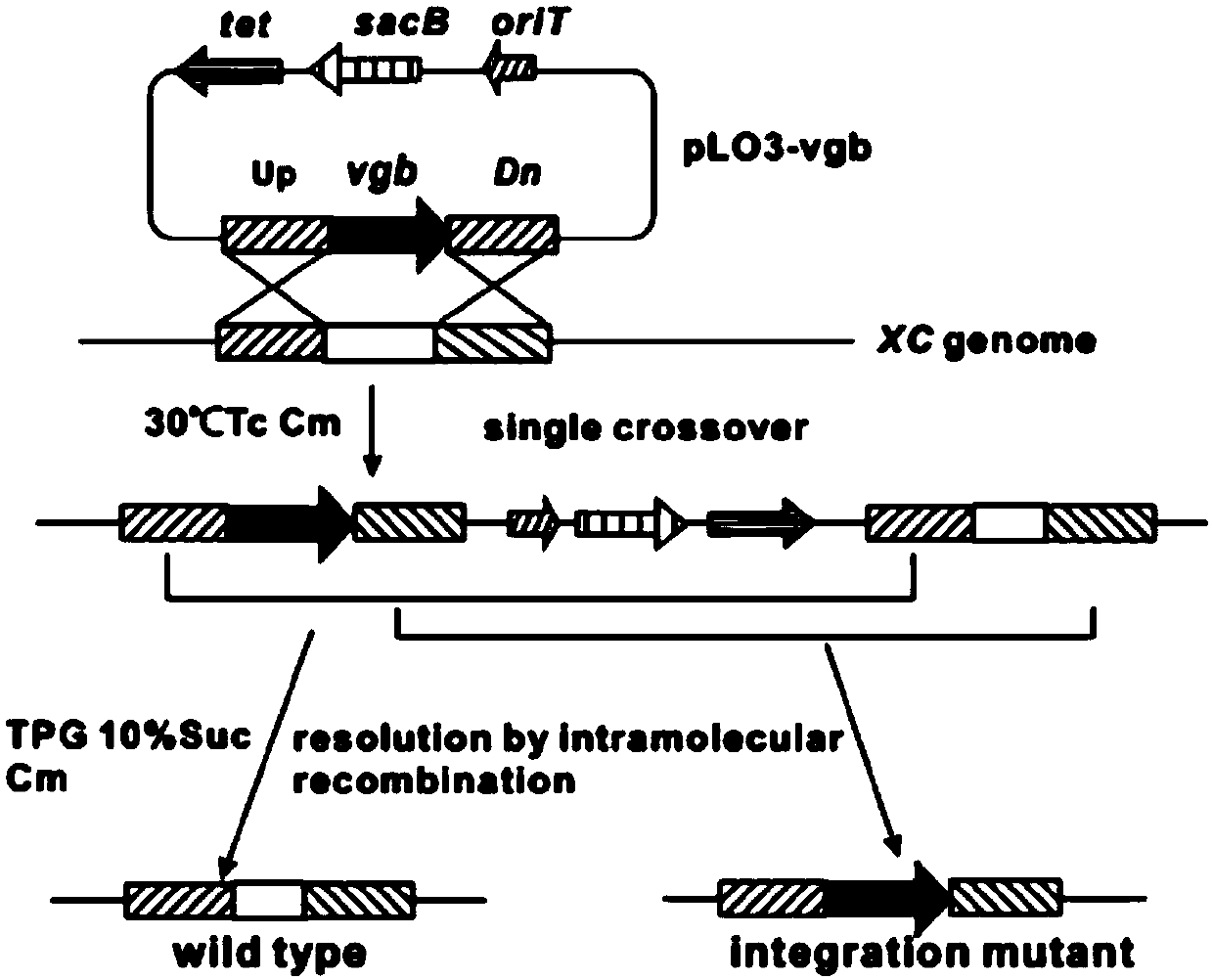

[0096] Embodiment 3: the construction of white xanthan gum mutant genetic engineering strain:

[0097] Pick a single colony of MHZ-20000 on the plate medium and inoculate it to contain Cm r 5ml of seed culture medium, cultured at 200rpm in a constant temperature shaker at 30°C for 14h, and picked a single colony of E.coli s17 / pLO3-vgb until it contained tet r In the LB liquid medium, cultured in a constant temperature shaker at 37°C at 200rpm for 8h, 5ml of each of the two strains was centrifuged at 6000rpm for 5min to collect the bacteria, and 10mmol / L MgSO 4 The solution was washed twice, centrifuged, and then washed with 200ul of MgSO 4 Resuspend the bacteria in the solution, mix MHZ-20000 and E.coli s17 / pLO3-vgb according to the ratio of 2:1, then suction filter until the pore size is placed on a filter membrane of 0.22 μm, and put the filter membrane with the bacteria facing up On the non-resistance plate, incubate for 12 hours in a constant temperature incubator at 30°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com