Concrete protective agent and preparation method thereof

A protective agent and concrete technology, which is applied in the field of concrete protective agent and its preparation, can solve the problems of poor durability of concrete, and achieve the effects of good water resistance, convenient operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

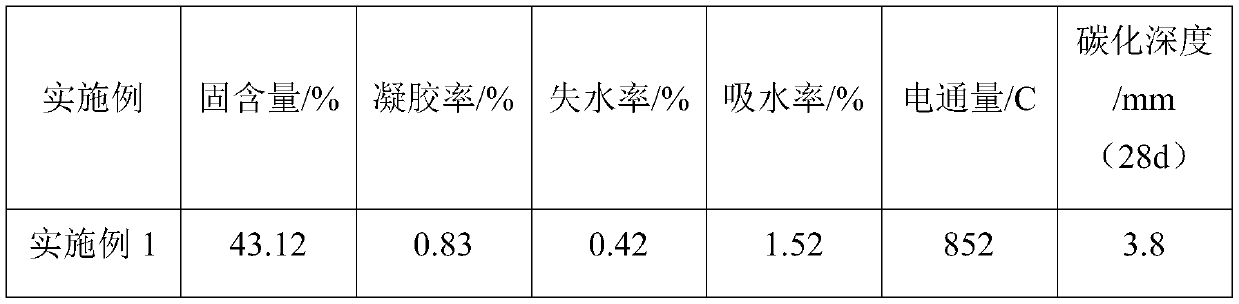

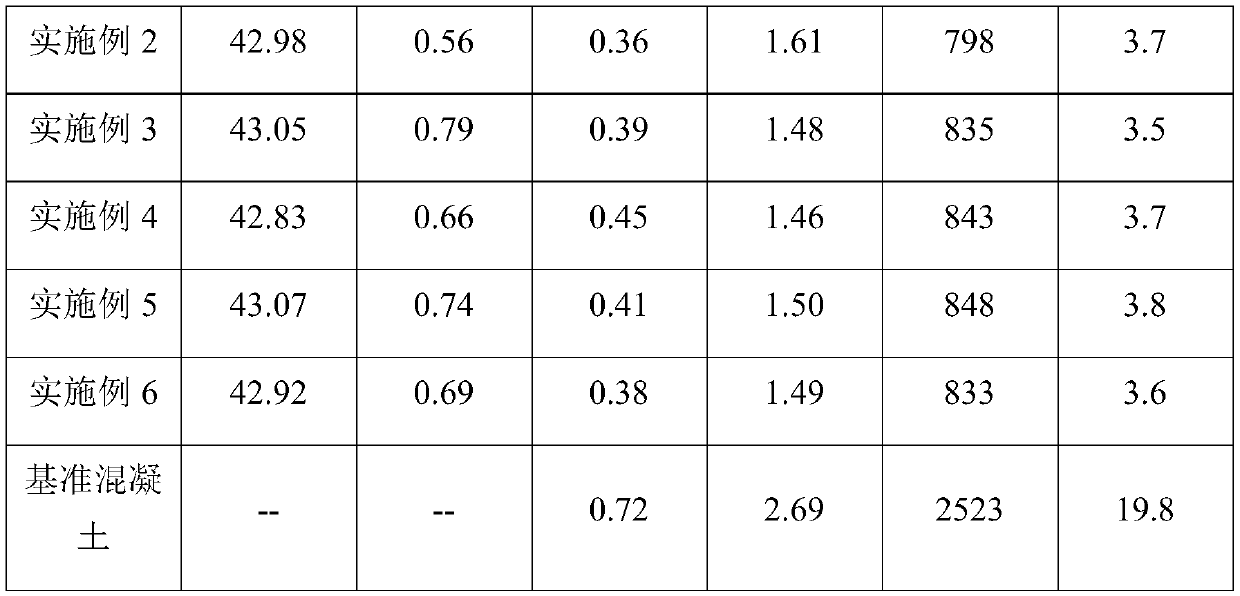

Examples

Embodiment 1

[0028] A concrete protective agent, comprising the following raw material components in parts by mass: 22 parts of polyurethane emulsion; 19 parts of butyl acrylate; 15 parts of methyl methacrylate; 0.2 parts of acrylic acid; 3 parts of diacetone propionamide; 0.8 parts of sodium persulfate 3 parts; 3 parts of adipic acid dihydrazide; 38 parts of deionized water.

[0029] Wherein, the polyurethane emulsion includes the following raw material components in parts by mass: 2 parts of polyoxypropylene glycol; 4 parts of castor oil; 3 parts of diphenylmethane diisocyanate; 0.6 part of dimethylol propionic acid; 25 parts of acetone; 0.2 parts of dibutyltin laurate; 0.2 parts of triethylamine; 65 parts of deionized water.

[0030] The preparation method of above-mentioned concrete protective agent, comprises the steps:

[0031] (1) After mixing polyoxypropylene glycol, castor oil and diphenylmethane diisocyanate in a reactor under a nitrogen atmosphere, after reacting at a constant ...

Embodiment 2

[0037] A concrete protective agent, comprising the following raw material components in parts by mass: 21 parts of polyurethane emulsion; 20 parts of butyl acrylate; 16 parts of methyl methacrylate; 0.3 parts of acrylic acid; 4 parts of diacetone propionamide; 4 parts; 4 parts of adipic acid dihydrazide; 35 parts of deionized water.

[0038] Wherein, the polyurethane emulsion includes the following raw material components in parts by mass: 4 parts of polyoxypropylene glycol; 5 parts of castor oil; 3 parts of diphenylmethane diisocyanate; 1 part of dimethylol propionic acid; 28 parts of acetone; 0.5 parts of dibutyltin laurate; 0.5 parts of triethylamine; 58 parts of deionized water.

[0039] The preparation method of above-mentioned concrete protective agent, comprises the steps:

[0040] (1) After mixing polyoxypropylene glycol, castor oil and diphenylmethane diisocyanate in a reactor under a nitrogen atmosphere, after reacting at a constant temperature of 45°C for 20 minutes,...

Embodiment 3

[0046] A concrete protective agent, comprising the following raw material components in parts by mass: 20 parts of polyurethane emulsion; 21 parts of butyl acrylate; 17 parts of methyl methacrylate; 0.41 parts of acrylic acid; 4 parts of diacetone propionamide; 4 parts; 4 parts of adipic acid dihydrazide; 32 parts of deionized water.

[0047] Wherein, the polyurethane emulsion includes the following raw material components in parts by mass: 6 parts of polyoxypropylene glycol; 3 parts of castor oil; 4 parts of diphenylmethane diisocyanate; 0.3 part of dimethylol propionic acid; 30 parts of acetone; 0.3 parts of dibutyltin laurate; 0.4 parts of triethylamine; 56 parts of deionized water.

[0048] The preparation method of above-mentioned concrete protective agent, comprises the steps:

[0049] (1) After mixing polyoxypropylene glycol, castor oil and diphenylmethane diisocyanate in a reactor under a nitrogen atmosphere, after reacting at a constant temperature of 45°C for 20 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com