Preparation method of resin-reinforced wood

A technology of resin reinforcement and wood, which is applied in wood treatment, impregnated wood, wood impregnation, etc., can solve the problems of environmental protection, poor wear resistance, easy oxidation of resin, etc., achieve low wear, enhanced filling effect, The effect of enhanced adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

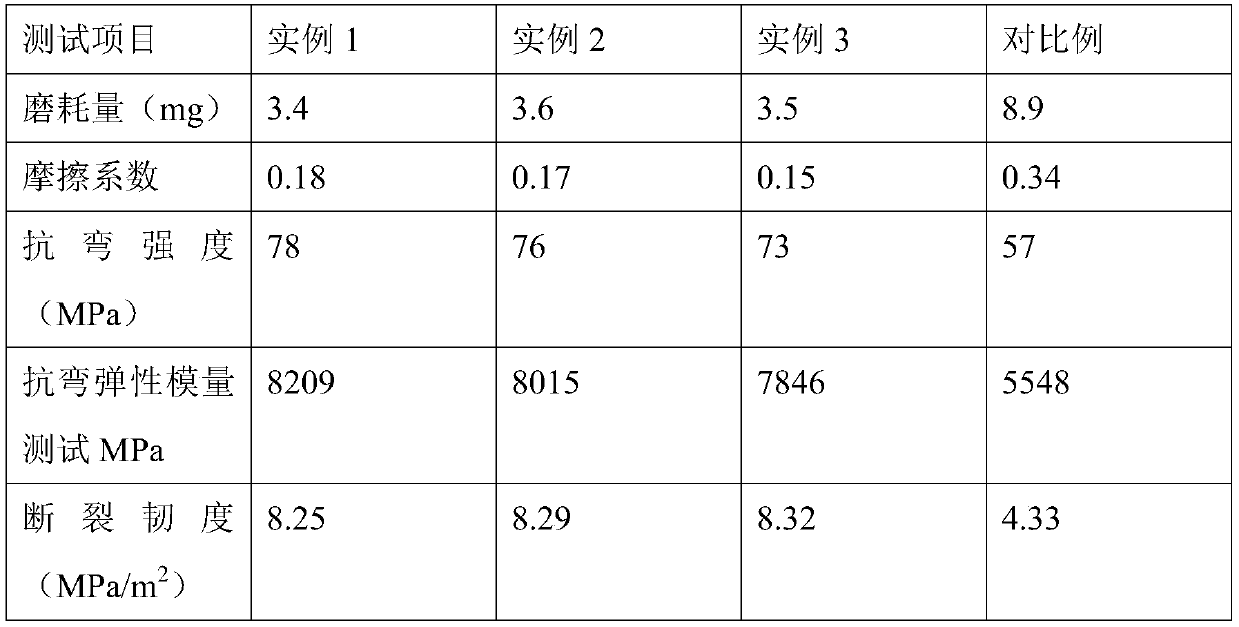

example 1

[0030]Take bauxite and place it in a ball mill for ball milling for 30 minutes to obtain bauxite particles with a particle size of 0.5. Put 80 mL of soybean oil in a beaker and heat up to 200. Then add 30 g of bauxite particles into the beaker and stir for 20 minutes to obtain Modified bauxite; in parts by weight, mix 20 parts of vinylidene fluoride rubber and 50 parts of polytetrafluoroethylene, add them to the open mill, and then add 10 parts of alumina powder and 8 parts of modified bauxite Carry out mixing in an open mill, control the mixing temperature to 300°C, and obtain the mixed rubber; put the poplar wood into a temperature-adjusting and humidity-adjusting box, and heat and boil it in water at a relative humidity of 80% and a temperature of 80°C After treatment for 3 hours, put the boiled poplar wood into a pressure tank, and carry out blasting treatment under the conditions of a pressure of 1.2MPa and a temperature of 80°C. When the pressure reaches the specified val...

example 2

[0032] Put the bauxite in a ball mill and mill it for 40 minutes to obtain bauxite particles with a particle size of 1.0 mm. Put 90 mL of soybean oil in a beaker, heat up to 220 ° C, then add 0 g of bauxite particles into the beaker, and stir 25min to obtain modified bauxite; in parts by weight, 30 parts of vinylidene fluoride rubber and 60 parts of polytetrafluoroethylene were mixed, added to the open mill, and then 15 parts of alumina powder, 10 parts of modified aluminum Put the bauxite into the open mill for mixing, control the mixing temperature to 350°C to obtain the mixed rubber; take the poplar wood and put it in a temperature-adjusting and humidity-adjusting box, and put it under the conditions of relative humidity of 85% and temperature of 90°C Heat and boil for 5 hours, put the boiled poplar wood into a pressure tank, and carry out blasting treatment under the conditions of a pressure of 2.5MPa and a temperature of 90°C. When the pressure reaches the specified value,...

example 3

[0034] Put bauxite in a ball mill and mill for 35 minutes to obtain bauxite particles with a particle size of 0.7mm. Put 85mL of soybean oil in a beaker, heat up to 220°C, then add 35g of bauxite particles into the beaker, and stir 23min to obtain modified bauxite; in parts by weight, 25 parts of vinylidene fluoride rubber and 55 parts of polytetrafluoroethylene were mixed and added to the open mill, and then 13 parts of alumina powder and 9 parts of modified aluminum Put the bauxite into the open mill for mixing, control the mixing temperature to 330°C to obtain the mixed rubber; take the poplar wood and put it in a temperature-adjusting and humidity-adjusting box, under the conditions of a relative humidity of 83% and a temperature of 85°C Heat and boil for 4 hours, put the boiled poplar wood into a pressure tank, and carry out blasting treatment at a pressure of 1.5MPa and a temperature of 85°C. When the pressure reaches the specified value, quickly open the pressure relief ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com