Polylactic acid/polycaprolactone three-dimensional porous composite monolithic column material and preparation method thereof

A polycaprolactone, three-dimensional porous technology, which is applied in the field of polylactic acid/polycaprolactone three-dimensional porous composite monolithic column material and its preparation, can solve the problems of poor mechanical properties of materials and complex technological processes, and achieve high porosity, Wide application prospects, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

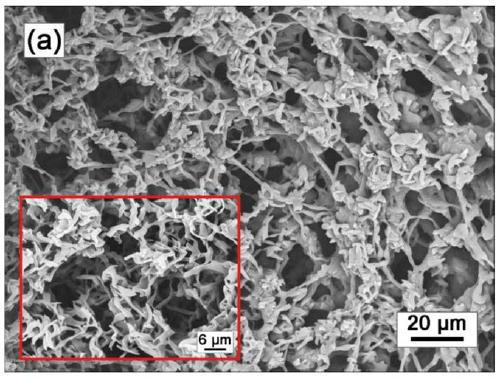

Embodiment 1

[0032] A polylactic acid / polycaprolactone three-dimensional porous composite monolithic column material is mainly prepared by the following steps:

[0033] (1) Weigh 0.3555g of polylactic acid particles and 0.0395g of polycaprolactone powder with ME104E Mettler-Tolly electronic balance, dissolve in 2mL of dichloromethane, and obtain polylactic acid / polycaprolactone in a steady state blended solution;

[0034] (2) Under the stirring of a magnetic stirrer, add 1.5 mL of n-hexane dropwise to the cloud point in the polylactic acid / polycaprolactone blend solution, so that the polymer solution system changes from a stable state to a metastable state;

[0035] (3) Stand still for 24 hours at 25°C to obtain a wet bulk material and take it out;

[0036] (4) Submerge the bulk material in methanol and place it on a shaker to vibrate, replace the methanol solution every once in a while, take it out after several times, and dry it in vacuum at room temperature for 3 hours to obtain a poro...

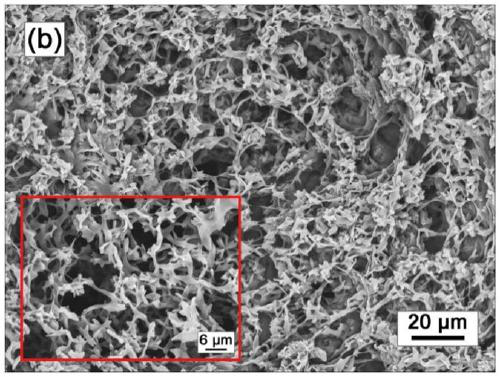

Embodiment 2

[0038] A polylactic acid / polycaprolactone three-dimensional porous composite monolithic column material is mainly prepared by the following steps:

[0039] (1) Weigh 0.316g of polylactic acid particles and 0.072g of polycaprolactone powder with ME104E Mettler-Tolly electronic balance, dissolve in 2mL of dichloromethane, and obtain polylactic acid / polycaprolactone in a steady state blended solution;

[0040] (2) Under the stirring of a magnetic stirrer, add 1.5 mL of n-hexane dropwise to the cloud point in the polylactic acid / polycaprolactone blend solution, so that the polymer solution system changes from a stable state to a metastable state;

[0041] (3) Stand still for 24 hours at 25°C to obtain a wet bulk material and take it out;

[0042] (4) Submerge the bulk material in anhydrous methanol and place it on a shaker to vibrate, replace the methanol solution every once in a while, take it out after several times, and dry it in vacuum at room temperature for 3 hours to obtai...

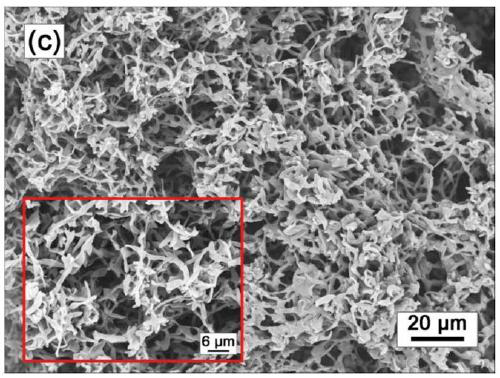

Embodiment 3

[0044] A polylactic acid / polycaprolactone three-dimensional porous composite monolithic column material is mainly prepared by the following steps:

[0045] (1) Weigh 0.2765g of polylactic acid granules and 0.1185g of polycaprolactone powder with ME104E Mettler-Tolly electronic balance, dissolve in 2mL of dichloromethane to obtain polylactic acid / polycaprolactone in a steady state blended solution;

[0046] (2) Under the agitation of a magnetic stirrer, add 1.4 mL of n-hexane dropwise to the cloud point in the polylactic acid / polycaprolactone blend solution, so that the polymer solution system changes from a stable state to a metastable state;

[0047] (3) Stand still for 24 hours at 25°C to obtain a wet bulk material and take it out;

[0048] (4) Submerge the bulk material in anhydrous methanol and place it on a shaker to vibrate, replace the methanol solution every once in a while, take it out after several times, and dry it in vacuum at room temperature for 3 hours to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com