A multi-card-point semi-automatic rounding device for log rounding processing

A semi-automatic, point-type technology, applied in grinding drives, metal processing equipment, control of workpiece feed motion, etc., can solve the problems of low uniformity, low safety, low efficiency, etc. The effect of increasing the grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

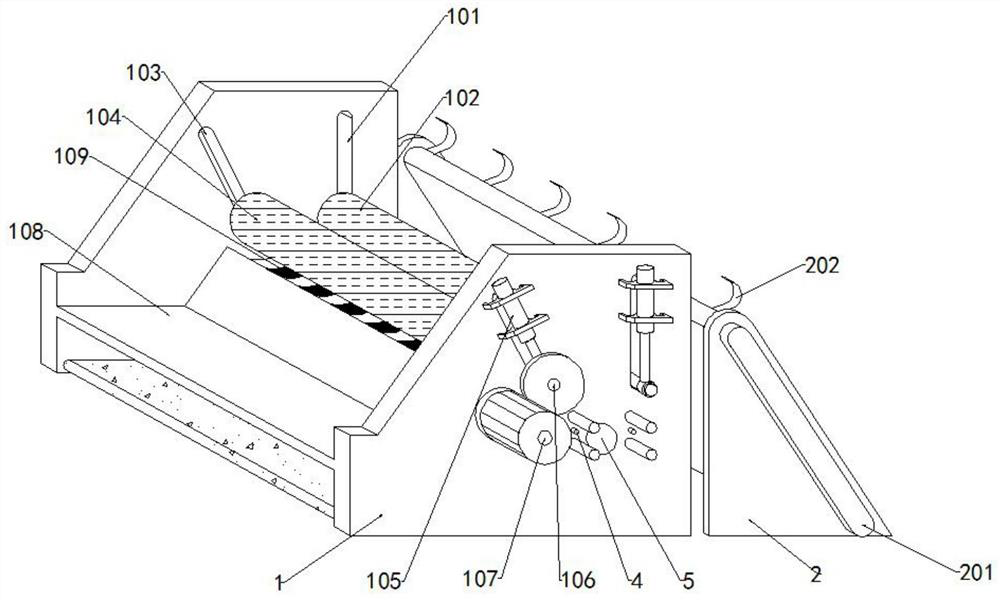

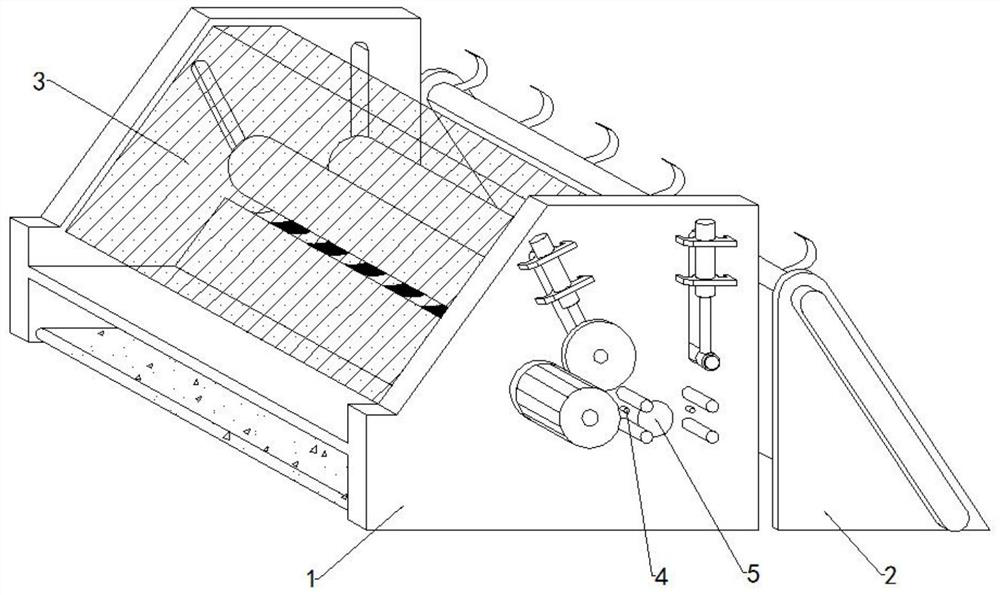

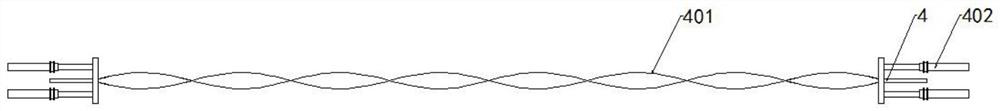

[0028] see Figures 1 to 8, in the embodiment of the present invention, including device housing 1, vertical chute 101, grinding roller 102, inclined chute 103, grinding roller 2 104, hydraulic rod 105, gear 106, motor 107, lead-out plate 108, slag discharge hole 109 , lifting bracket 2, conveyor belt 201, arc-shaped barb 202, glass cover 3, auxiliary grinding pile 4, steel bar 401, hydraulic rod 2 402, guide wheel 5, telescopic bracket 501, infrared generator 6 and infrared receiver 7, A vertical chute 101 is nested on the front and rear sides of the right side of the device shell 1, and a grinding roller 102 is connected to the vertical chute 101 through bearing rotation, and an oblique chute 103 is nested on the front and rear sides of the right side of the device shell 1 , and the inclined chute 103 is located on the right side of the vertical chute 101, the inner surface of the inclined chute 103 is connected with the grinding roller 2 104 through bearing rotation, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com