A Dumas azotometer reaction tube

A nitrogen analyzer and reaction tube technology, used in the detection of total nitrogen content in urea, can solve problems such as damage, no solution, strong corrosiveness, etc., to ensure reliability, eliminate adverse interference, and reduce effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] The primary combustion tube is filled sequentially from bottom to top:

[0075] (1-1) spacer ring;

[0076] (1-2) metal mesh;

[0077] (1-3) Corundum balls with a height of 10mm;

[0078] (1-4) a mixture of 80g copper oxide and 30g corundum balls;

[0079] (1-5) Corundum balls with a height of 10mm;

[0080] (1-6) Ash tube.

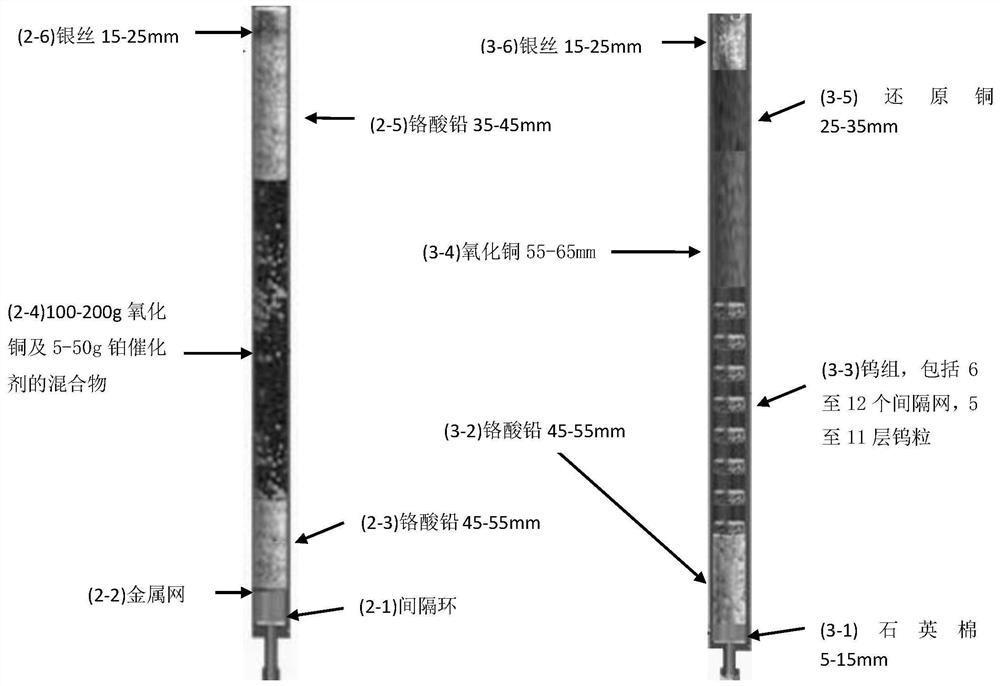

[0081] The secondary combustion tube is filled sequentially from bottom to top:

[0082] (2-1) spacer ring;

[0083] (2-2) metal mesh;

[0084] (2-3) Lead chromate with a height of 50mm;

[0085] (2-4) the mixture of 170g copper oxide and 15g platinum catalyst;

[0086] (2-5) Lead chromate with a height of 40mm;

[0087] (2-6) Silver wires with a height of 20 mm.

[0088] The reduction tube is filled sequentially from bottom to top:

[0089] (3-1) Quartz wool with a height of 10mm;

[0090] (3-2) Lead chromate with a height of 50mm;

[0091] (3-3) Tungsten group, including 9 spacer nets, 8 layers of tungsten particles, each layer of tu...

Embodiment 2

[0096] The primary combustion tube is filled sequentially from bottom to top:

[0097] (1-1) spacer ring;

[0098] (1-2) metal mesh;

[0099] (1-3) Corundum balls with a height of 10mm;

[0100] (1-4) a mixture of 80g copper oxide and 30g corundum balls;

[0101] (1-5) Corundum balls with a height of 10mm;

[0102] (1-6) Ash tube.

[0103] The secondary combustion tube is filled sequentially from bottom to top:

[0104] (2-1) spacer ring;

[0105] (2-2) metal mesh;

[0106] (2-3) Lead chromate with a height of 45 mm;

[0107] (2-4) the mixture of 100g copper oxide and 5g platinum catalyst;

[0108] (2-5) Lead chromate with a height of 35mm;

[0109] (2-6) Silver wires with a height of 15mm.

[0110] The reduction tube is filled sequentially from bottom to top:

[0111] (3-1) Quartz wool with a height of 5mm;

[0112] (3-2) Lead chromate with a height of 45mm;

[0113] (3-3) Tungsten group, including 6 spacer nets, 5 layers of tungsten particles, each layer of tung...

Embodiment 3

[0118] The primary combustion tube is filled sequentially from bottom to top:

[0119] (1-1) spacer ring;

[0120] (1-2) metal mesh;

[0121] (1-3) Corundum balls with a height of 10mm;

[0122] (1-4) a mixture of 80g copper oxide and 30g corundum balls;

[0123] (1-5) Corundum balls with a height of 10mm;

[0124] (1-6) Ash tube.

[0125] The secondary combustion tube is filled sequentially from bottom to top:

[0126] (2-1) spacer ring;

[0127] (2-2) metal mesh;

[0128] (2-3) Lead chromate with a height of 55 mm;

[0129] (2-4) the mixture of 200g copper oxide and 50g platinum catalyst;

[0130] (2-5) Lead chromate with a height of 45mm;

[0131] (2-6) Silver wires with a height of 25 mm.

[0132] The reduction tube is filled sequentially from bottom to top:

[0133] (3-1) Quartz wool with a height of 15mm;

[0134] (3-2) Lead chromate with a height of 55mm;

[0135] (3-3) Tungsten group, including 12 spacer nets, 11 layers of tungsten grains, 20g of tungsten ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com