A drag-reducing and heat-insulating polymer pipe, its preparation method and application

A technology of pipeline and hydrothermal method, applied in the field of pipeline, can solve the problems of increasing pipeline volume and material loss, the effect of drag reduction is not obvious, and it has no heat insulation effect, so as to save energy loss, improve multiple performance, and reduce cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Coating the liquid metal on the inner wall of the pipeline with a coating thickness of 2 microns, and oxidizing under air conditions to obtain a thin layer of metal oxide.

[0038] (2) Place the pipe vertically in 100 mL of growth solution, heat to 90° C. under airtight conditions, and react for 10 hours to form ZnO nanostructures on the inner wall surface of the pipe.

[0039] (3) Add an appropriate amount of fluorosilane dropwise to the dry ZnO nanostructure, place it in a sealed container, heat it to 90°C under the condition of vacuum degree -0.1Mpa, and keep it for 6 hours to form a function with low surface energy Surface, so as to make drag reduction and heat insulation pipeline.

[0040] The formula of the growth liquid used in this example: 0.30 g of hexamethylenetetramine, 0.70 g of zinc nitrate, and 100 ml of deionized water.

experiment example 1

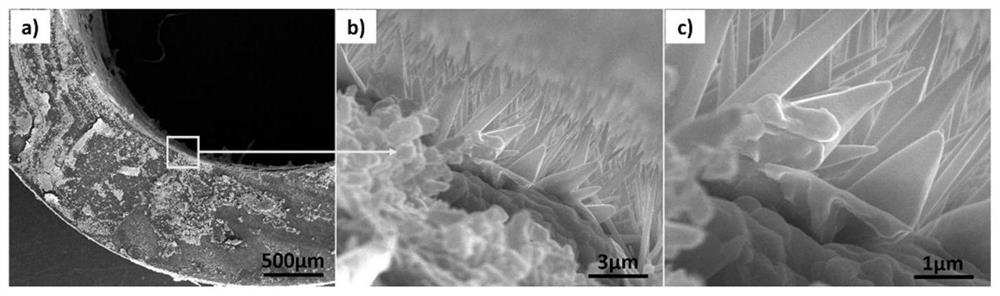

[0042] Carry out electron microscope scanning to the pipeline inner wall that embodiment 1 makes, the results are shown in figure 1 . The results show that the inner wall of the pipeline is modified by the nanocone structure.

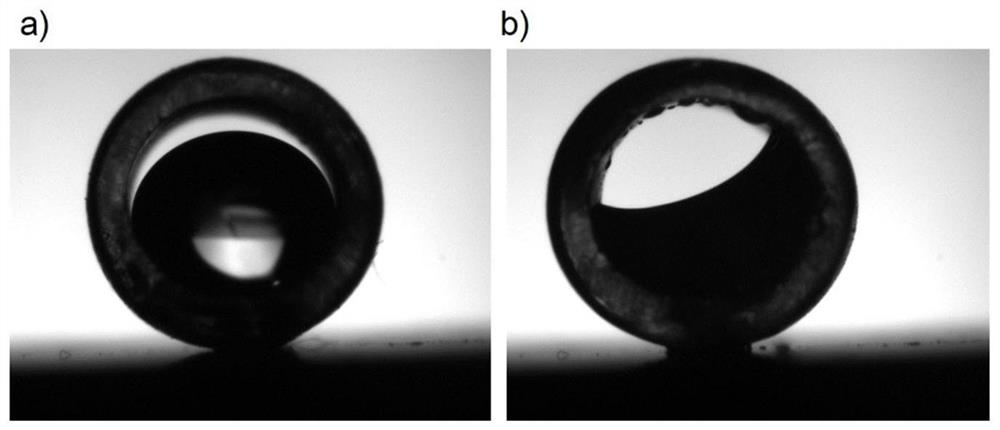

[0043] Detect the hydrophobic angle of the pipeline inner wall before and after the modification of the method of embodiment 1 respectively, the results are shown in figure 2 . The results showed that, compared with before modification ( figure 2 b) Compared with the modified ( figure 2 a) The hydrophobic angle of the inner wall of the pipeline is significantly improved.

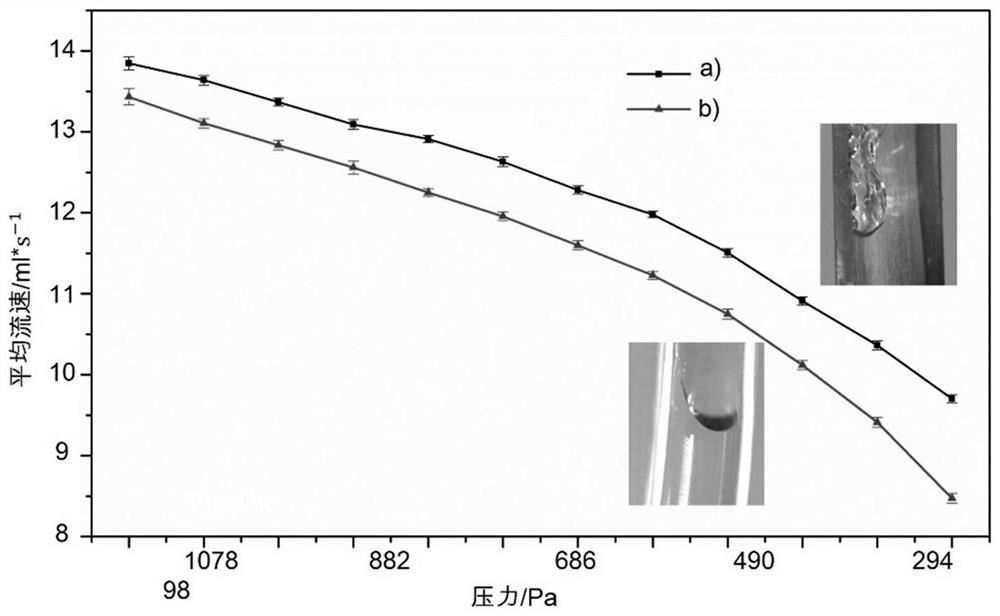

[0044] Detect respectively the turbulence performance of the pipeline inner wall before and after modification of the method of embodiment 1, the results are shown in image 3 . The results show that the fluid after modification ( image 3 a) The internal flow is a form of turbulence, the fluid is easy to break away from the surface, and the viscous force is very small; whil...

Embodiment 2

[0047] (1) Coating the liquid metal on the inner wall of the pipeline with a coating thickness of 5 microns and oxidizing under air conditions to obtain a thin metal oxide layer.

[0048] (2) Place the pipe vertically in the growth solution, heat to 90° C. under airtight conditions, and react for 12 hours to form ZnO nanostructures on the inner wall surface of the pipe.

[0049](3) Add an appropriate amount of fluorosilane dropwise to the dry ZnO nanostructure, heat it to 80°C under the condition of vacuum degree -0.1Mpa, and keep it for 8 hours to form a functional surface with low surface energy, so as to obtain a reduced surface energy. Resistance, insulation pipe.

[0050] The formula of the growth liquid used in this example: 0.30 g of hexamethylenetetramine, 0.20 g of zinc nitrate, and 100 ml of deionized water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com