Preparation method of glycitein purified product

A technology of soybean yellowin, pure product, applied in the field of preparation of pure soybean yellowin, which can solve the problems of difficult extraction of soybean yellowin products, and achieve the effect of simple process and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

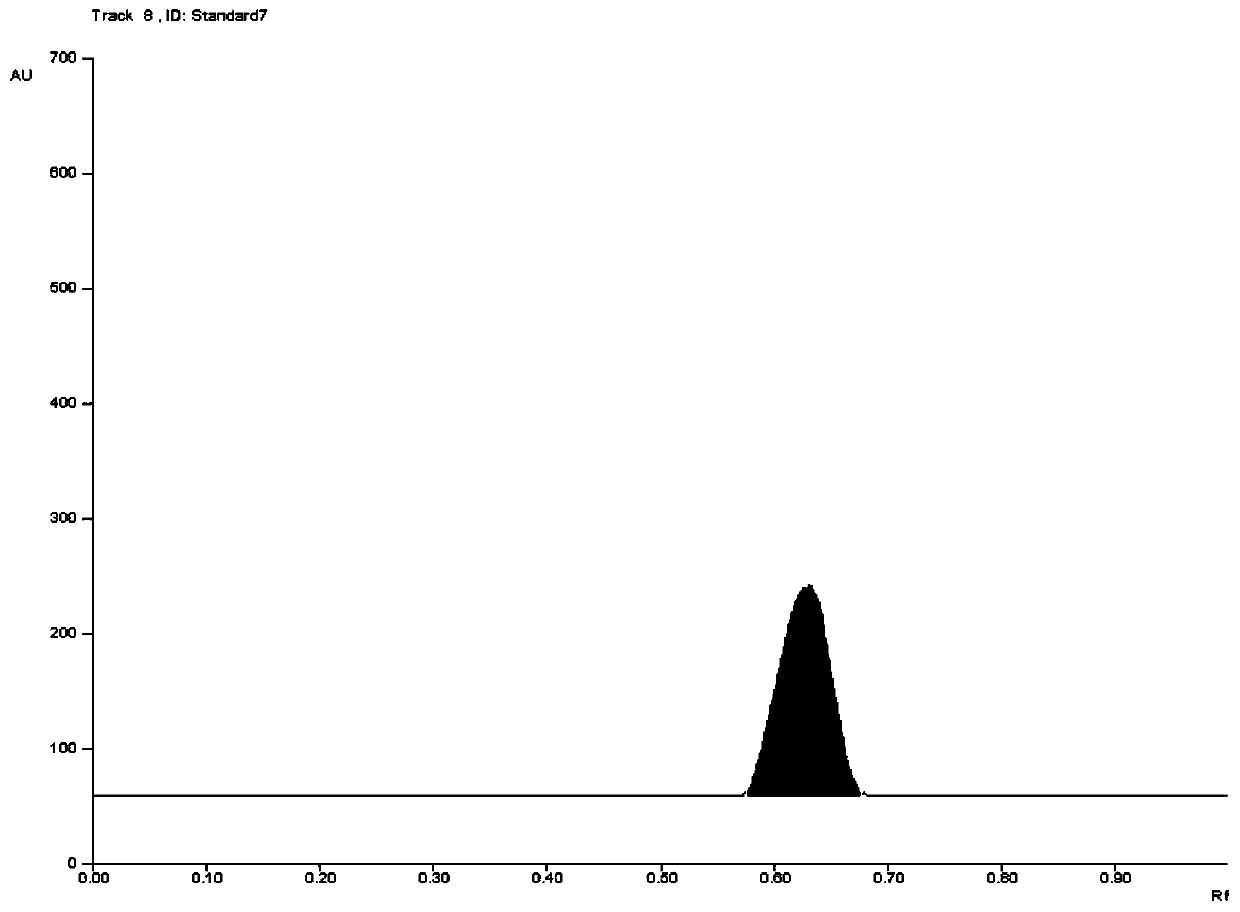

Image

Examples

Embodiment 1

[0041] Take 2L of soymilk water discharged during the production of soybean protein by the process of alkali extraction and acid precipitation, and let it settle naturally for 4 hours to obtain 500mL of yellow liquid in the lower layer. Add 1g NaOH to the liquid, stir it magnetically for 0.5h, let it stand for two layers, and the upper layer is 450mL , lower layer 50mL (precipitation), separate the two layers, add ethyl acetate 250mL and 50mL to the upper and lower layers in turn, respectively, magnetically stir for 0.5h to extract, separate into two layers after static, and take the upper ethyl acetate layer respectively to obtain 300mL and 50mL. The two were rotary evaporated to dryness respectively to obtain a dry residue. Add 50 mL and 10 mL of ethyl acetate to the dry residue, respectively. Vortex to dissolve as completely as possible. Centrifuge at 6000r / min for 10min, take the supernatant and spin evaporate to dryness respectively. It is detected that the upper layer ...

Embodiment 2

[0043] Take 2L of soymilk water discharged during the production of soybean protein by alkali extraction and acid precipitation process, and let it sit naturally for 5 hours to obtain 500mL of yellow liquid in the lower layer. Add 1.5g NaOH to the liquid, stir it magnetically for 45min, and divide it into two layers at rest. The upper layer is 470mL. Lower layer 30mL (with precipitation). Add 270mL and 30mL of ethyl acetate to the upper and lower layers in turn, respectively, magnetically stir each for 0.5h, stand still and separate into two layers, take the upper ethyl acetate layer respectively, and obtain 310mL and 30mL of liquid, respectively, and rotary evaporate the two to obtain dry residue , add ethyl acetate 50mL and 10mL respectively to the dry residue, vortex to dissolve as completely as possible. After centrifugation at 6000r / min for 12min, the supernatants were taken and evaporated to dryness respectively. It was detected that each of them was a single component g...

Embodiment 3

[0045] Take 2L of soymilk water discharged during the production of soybean protein by alkali extraction and acid precipitation process, and let it sit naturally for 6 hours to obtain 500mL of yellow liquid in the lower layer. 20mL (with precipitation). Add 280mL and 20mL of ethyl acetate to the upper and lower layers in turn, respectively, magnetically stir for 1h, stand still and divide into two layers, then take the upper ethyl acetate layer, respectively, to obtain 320mL and 20mL of liquid, and rotary evaporate the two to obtain dry residue, Add 50 mL and 10 mL of ethyl acetate to the dry residue, and vortex to dissolve it as completely as possible. After centrifugation at 6000r / min for 15min, the supernatants were taken and evaporated to dryness respectively. It was tested that each of them was a single component glycitein, 15.44mg and 0.28mg respectively, and the purity of glycitein was 98.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com