Nitroguanidine crystal and microchannel crystallization process and device of nitroguanidine

A crystallization device and micro-channel technology, applied in crystallization separation, oscillating crystallization, solution crystallization, etc., can solve the problems of inability to realize continuous production, a large amount of organic solvents, complicated processing procedures, etc., and achieve simple and controllable reaction conditions and easier washing. , the effect of high reaction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

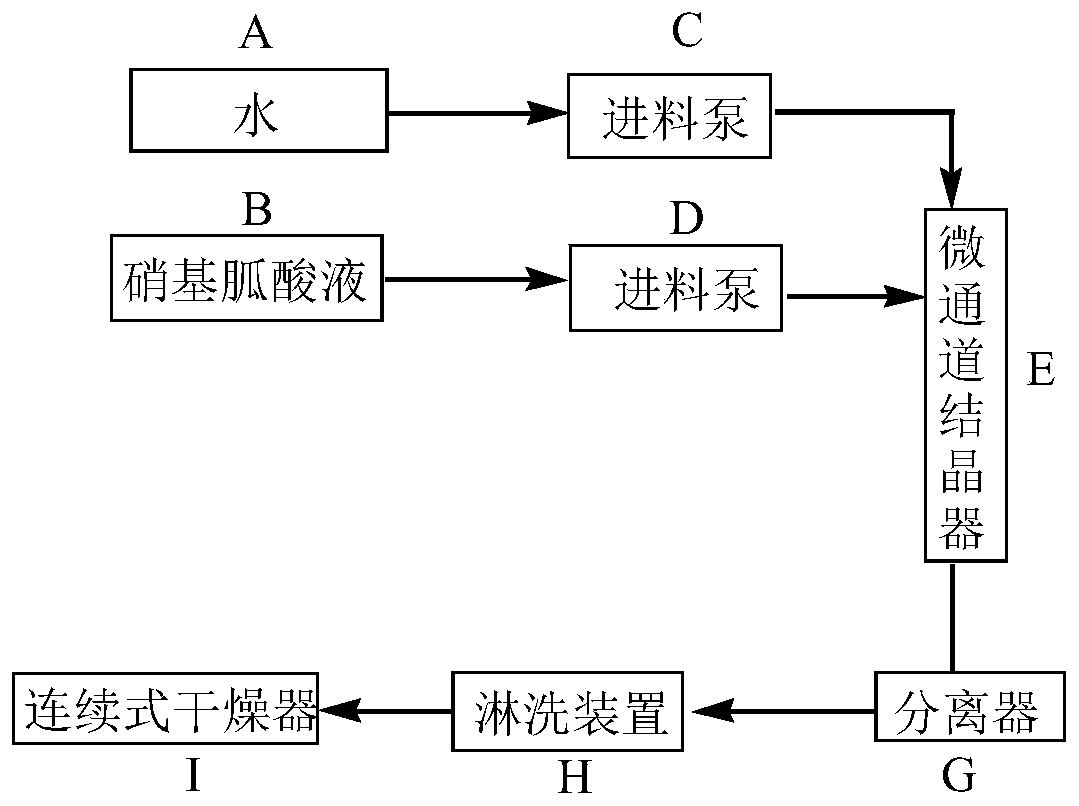

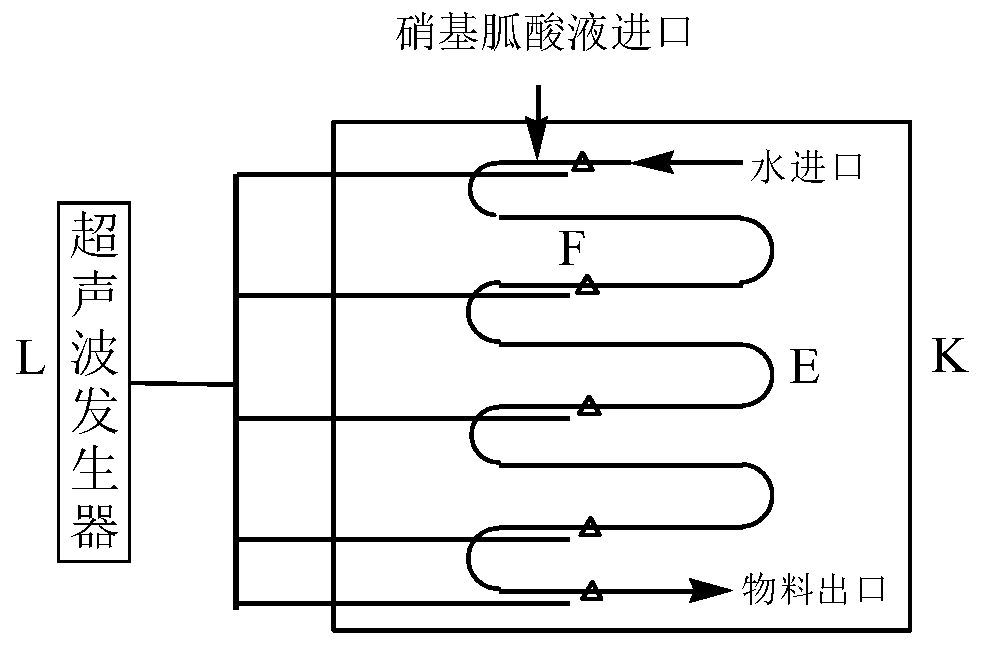

Embodiment 1

[0036] This experiment uses a stainless steel horizontal tubular microchannel crystallizer E with a length of 100m and an inner diameter of 2mm coated with anti-corrosion material. An ultrasonic probe F is added every 10m in the pipeline and placed in a constant temperature bath K at -5°C. Turn on the ultrasonic generator L, set the ultrasonic frequency at 20kHz, and the power at 1000W, and the nitroguanidine acid solution and water are respectively measured by the second metering pump D and the first metering pump D from the nitroguanidine acid solution storage tank B and the water storage tank A. The pump C is delivered to the reaction pipeline, the input flow rate of the nitroguanidine acid solution is 100mL / min, and the input flow rate of the water is 150mL / min. After the material is rapidly crystallized in the microchannel crystallizer, it is transported to the separator G, and the resulting The solid material is fully washed by the washing device H, and dehydrated in the ...

Embodiment 2

[0038] This experiment uses a stainless steel horizontal tubular microchannel crystallizer E with a length of 80m and an inner diameter of 4mm coated with anti-corrosion material. An ultrasonic probe F is added every 8m in the pipeline and placed in a constant temperature bath K at -5°C. Turn on the ultrasonic generator L, set the ultrasonic frequency at 22kHz, and the power at 1200W, and the nitroguanidine acid solution and water are respectively measured from the nitroguanidine acid solution storage tank B and the water storage tank A by the second metering pump D and the first metering pump. The pump C is delivered to the reaction pipeline, the input flow rate of the nitroguanidine acid solution is 150mL / min, and the input flow rate of the water is 180mL / min. After the material is rapidly crystallized in the microchannel crystallizer, it is transported to the separator G, and the resulting The solid material is fully washed by the washing device H, and dehydrated in the cont...

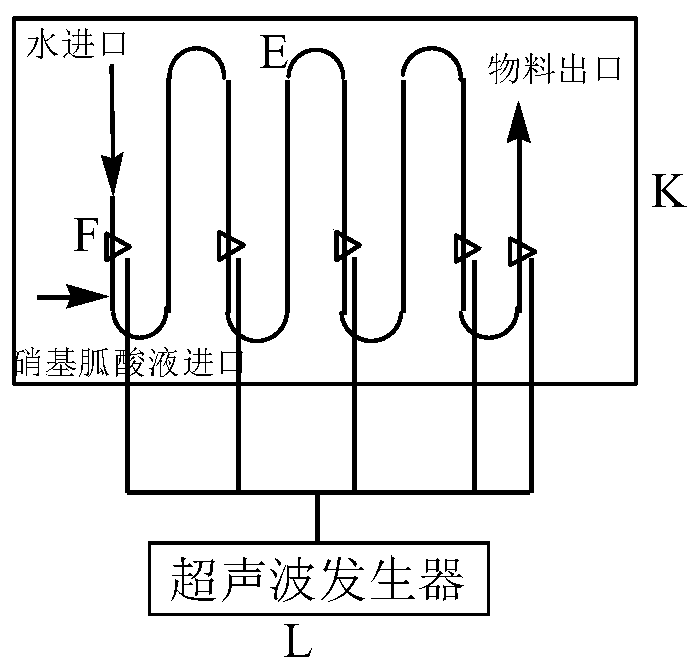

Embodiment 3

[0040] This experiment uses a stainless steel riser microchannel crystallizer E with a length of 50m and an inner diameter of 6mm coated with anti-corrosion material. An ultrasonic probe F is added every 4m in the pipeline and placed in a constant temperature bath at -3°C. Turn on the ultrasonic generator L, set the ultrasonic frequency at 30kHz, and the power at 1800W, and the nitroguanidine acid solution and water are respectively measured by the second metering pump D and the first metering pump D from the nitroguanidine acid solution storage tank B and the water storage tank A. The pump C is delivered to the reaction pipeline, the input flow rate of the nitroguanidine acid solution is 200mL / min, and the input flow rate of the water is 200mL / min. After the material is rapidly crystallized in the microchannel crystallizer, it is transported to the separator G, and the resulting The solid material is fully washed by the washing device H, and dehydrated in the continuous dryer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com