Circulating water automatic precise drug feeding system

A technology of dosing system and circulating water, which is applied in descaling and water softening, water/sewage treatment, water treatment parameter control, etc. It can solve the problem of inaccurate dosing amount, affecting the effect of circulating water treatment, and inconvenient dosing operation, etc. problems, to achieve the effect of increasing the range of water intake, convenient operation of dosing, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

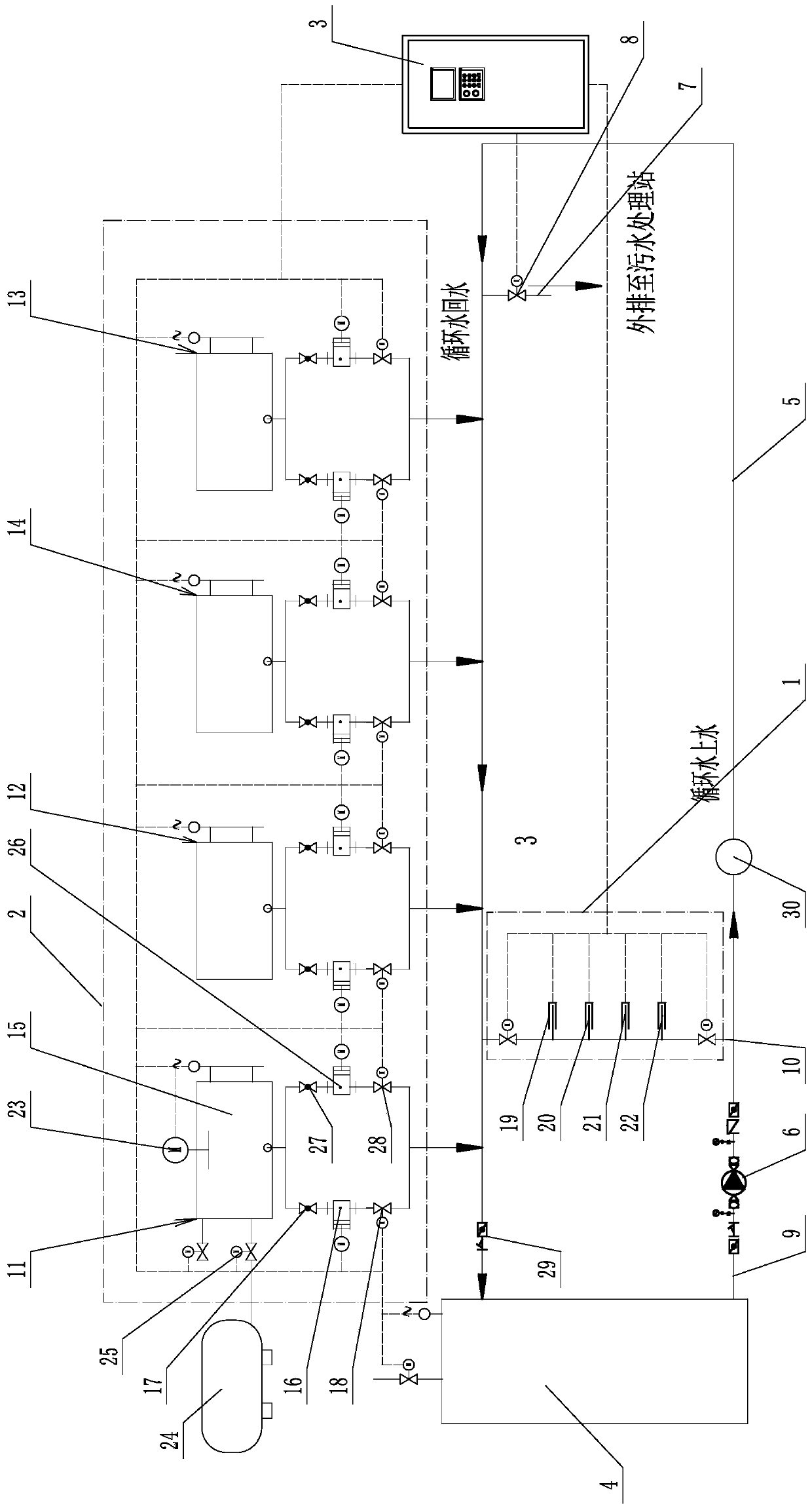

[0025] Embodiment 1: A kind of circulating water fully automatic precision dosing system (see attached figure 1 ), including circulating water delivery mechanism, water quality online detection device 1, precision dosing cabinet 2, controller 3, circulating water delivery mechanism including circulating water pool 4, circulating water pipe 5, circulating water pump 6, circulating water pipe connected to sewage branch pipe 7, sewage discharge The sewage electric valve 8 is installed on the branch pipe. One end of the circulating water pipe is connected to the outlet of the circulating water pump, and the other end is connected to the upper part of the circulating water pool. The water inlet of the circulating water pump is connected to the water intake pipe 9, which is connected to the lower part of the circulating water pool. The water quality online detection device is installed on the sampling branch pipe; the sulfuric acid filling device 11, the non-oxidizing bactericide fil...

Embodiment 2

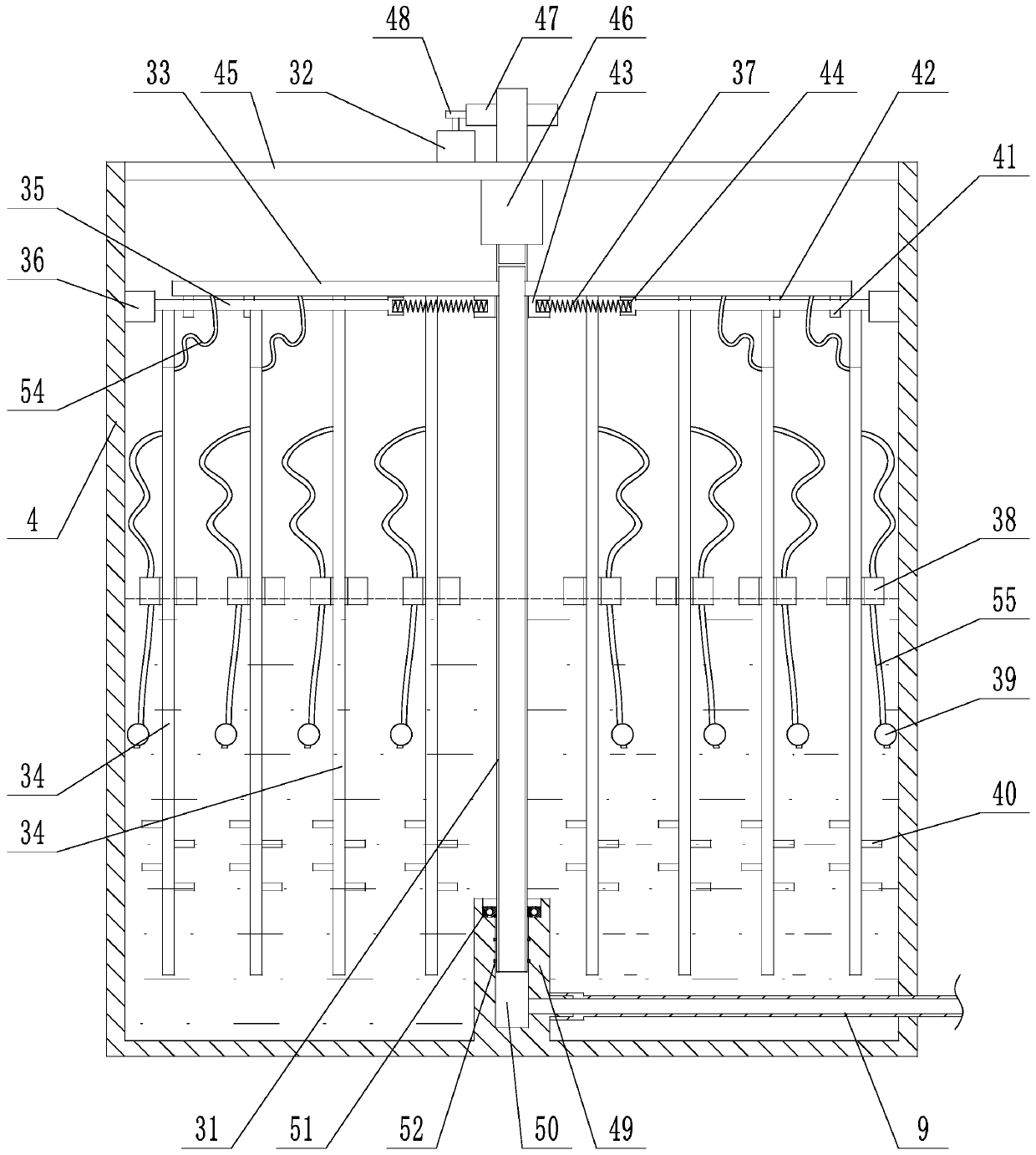

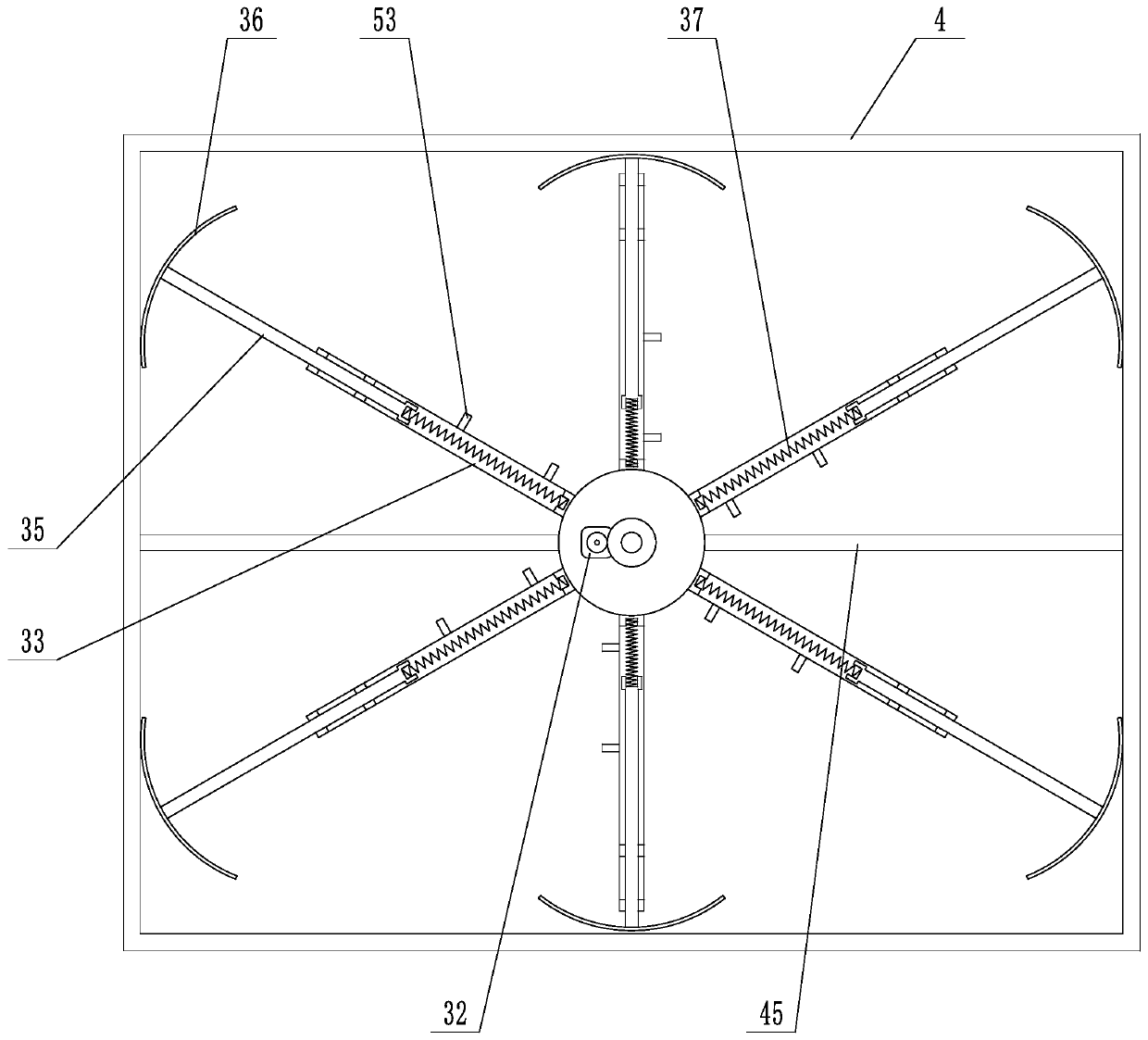

[0031] Embodiment 2: A kind of circulating water fully automatic precision dosing system (see attached figure 2 , attached image 3 ), its structure is similar to that of Embodiment 1, the main difference is that in this embodiment, a rotatable water inlet rotating pipe 31 is installed in the circulating pool, the water inlet rotating pipe is connected with the water intake pipe, and the upper end of the circulating pool is installed to drive the water inlet to rotate The drive motor 32 for the pipe rotation, the water inlet rotating pipe is evenly distributed near the upper end position to connect with several horizontal pipes 33, the horizontal pipes are connected with several water intake vertical pipes 34, and the horizontal pipes are connected with slide bars 35 that can slide radially. The end is connected with an arc-shaped retaining bar 36, and the abutment spring 37 is connected between the slide bar and the horizontal pipe. Connected, the opening position of the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com