Crushing equipment for traditional Chinese medicinal materials and using method thereof

A technology for traditional Chinese medicinal materials and equipment, which is applied in the field of wall breaking devices for traditional Chinese medicine powders, can solve problems such as equipment wear, temperature rise, and damage to nutrients, so as to reduce heat generation, slow down temperature rise, and reduce heat generation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

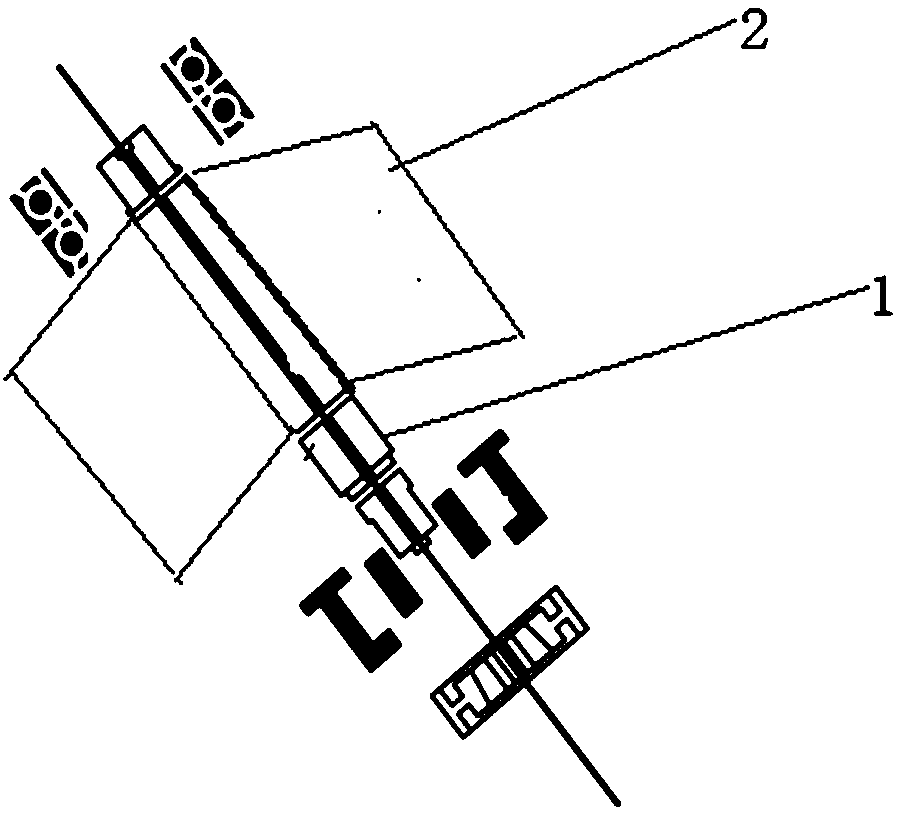

[0029] A wall-breaking device for Chinese medicinal materials, including a feeder, a wall-breaker and a discharge machine, the inlet of the feeder is used to input the medium to be broken, the outlet of the feeder is connected with the inlet of the main machine for breaking the wall, and the breaker The outlet of the wall host is connected to the inlet of the discharge machine, and the outlet of the discharge machine is used to output the medium after the wall is broken. The vacuum device with adjustable vacuum degree is installed in the feeder to vacuum the medium to be broken. Send it into the broken wall host, and select the gas pressure of 25~75KPa according to the weight of different Chinese medicinal materials. For example, pearl powder with a large specific gravity can use a pressure of 25KPa, and pollen with a small specific gravity can use a pressure of 75KPa. The feeding situation is adjusted to a suitable vacuum. If the degree of vacuum is too high, a large amount o...

Embodiment 2

[0032] Illustrate the usage method of the broken wall equipment of Chinese medicinal material by following example:

[0033] Put the pearl powder with a particle size of 50µm into the feeder, turn on the vacuum device of the feeder, set the pressure at 25KPa, the powder is sucked from the feeder into the wall breaking machine, and after being accelerated by the acceleration device, the initial The speed is above 10m / s. Turn on the cooling water of the breaker, the temperature of the cooling water is 10°C, the speed of the two sets of impact components in the breaker cabin is 2200rpm, and the direction is opposite. After the powder is continuously impacted and crushed, it travels from bottom to top in a tornado state, less than 1µm The powder is collected by the cyclone dust collector and the pipe dust collector, and the large particle powder returns to the cabin due to gravity to further break the wall. The broken wall machine can be operated continuously, the temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com