A cuo-cn peroxide composite catalyst for advanced oxidation technology and its preparation method and application

A technology of advanced oxidation technology and composite catalyst, which is applied in the field of CuO-CN peroxide composite catalyst of advanced oxidation technology and its preparation, can solve the problems of low effective utilization rate of oxidants, obstacles to wide application, narrow pH range, etc., and achieve good Prospect of industrial promotion and application, improvement of utilization rate, effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The embodiment of the present invention provides a method of preparing a CuO-CN peroxide composite catalyst of advanced oxidation techniques, and the steps specifically include:

[0038] The organic copper source and dihydroids were mixed in 5-35 ° C, and the mass ratio of copper element and dihydroid in the organic copper source was (0.01-0.5): 1, After stirring in a water bath at 50-90 ° C, it was evaporated. The resulting material was ground to obtain a CuO-CN composite catalyst for advanced oxidation technology.

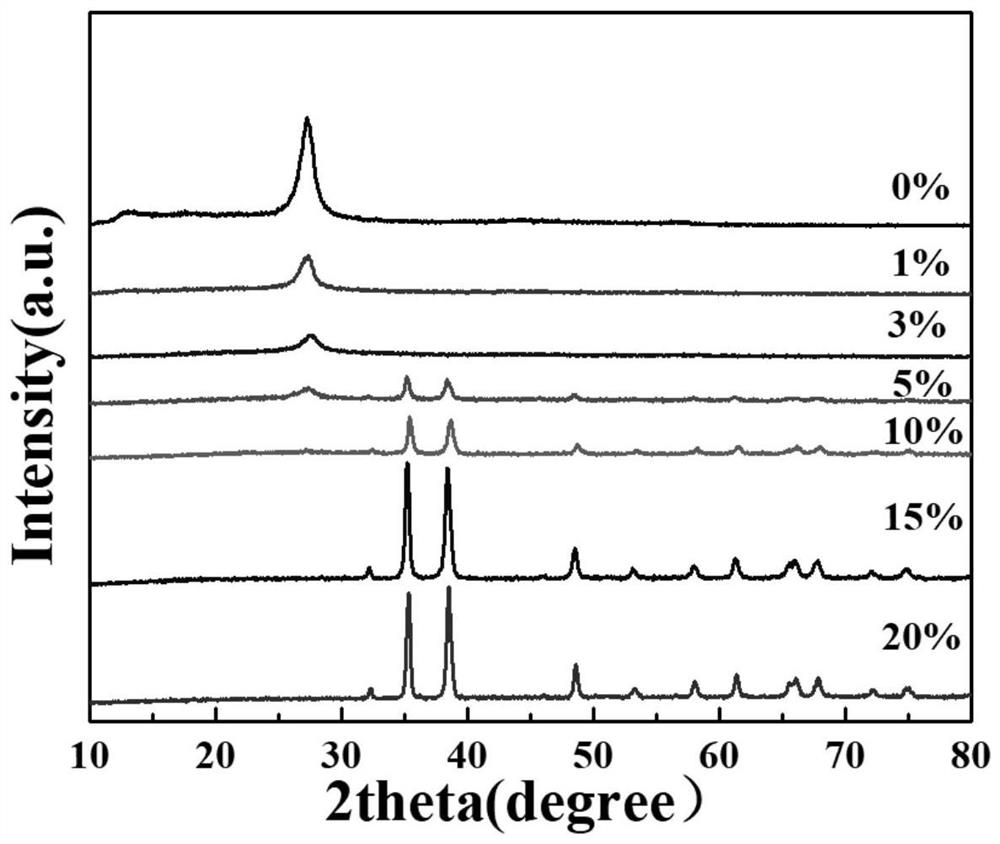

[0039]The resulting CuO-CN composite catalyst is a CuO and CN which are bonded to each other, the CuO is in contact with the interface between the two phases, and there is a chemical effect between the two-phase interfaces to account for the mass percentage of the composite catalyst. The content of copper elements is 1-70%.

[0040] The CuO-CN peroxide composite catalyst prepared by the above method is used in wastewater treatment, and contaminants in the wast...

Embodiment 1

[0043] This embodiment provides a method of preparing a CuO-CN peroxide composite catalyst for advanced oxidation techniques, and the steps specifically include:

[0044] The copper with copper, dihydroid in ethanol solvent was mixed at room temperature, and the mass ratio of copper element and dihydroid in copper of the acetate was 0.01: 1, i.e., the mass percentage of dihydroidia, After the copper is added, the water bath is stirred and stirred and evaporated. The resulting material was ground to obtain a CuO-CN composite catalyst for advanced oxidation technology.

[0045] Further, the present embodiment has also adjusted the amount of copper element to obtain a CuO-CN composite catalyst added to different copper, specifically, the mass ratio of copper elements in copper acetate and dihydroid is adjusted to 0: 1, 0.03: 1, 0.05: 1, 0.2: 1, 0.15: 1, 0.2: 1, ie, the amount of copper added is adjusted to 0%, 3%, 5%, 10% by the mass percentage of dihydroidia. 15%, 20%, other prepara...

Embodiment 2

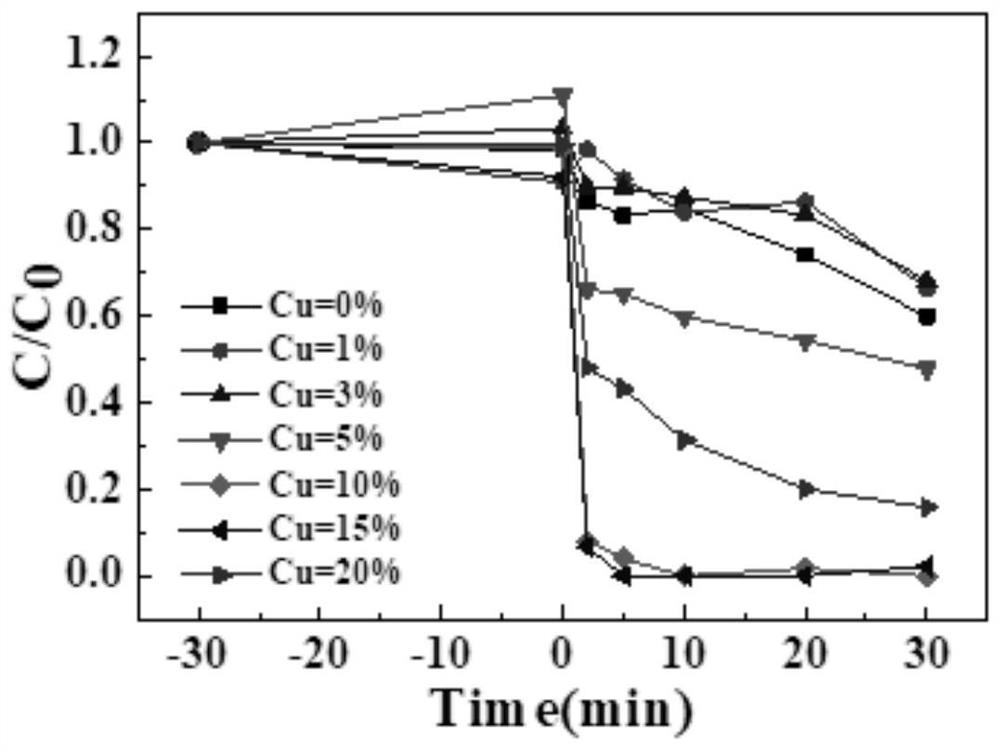

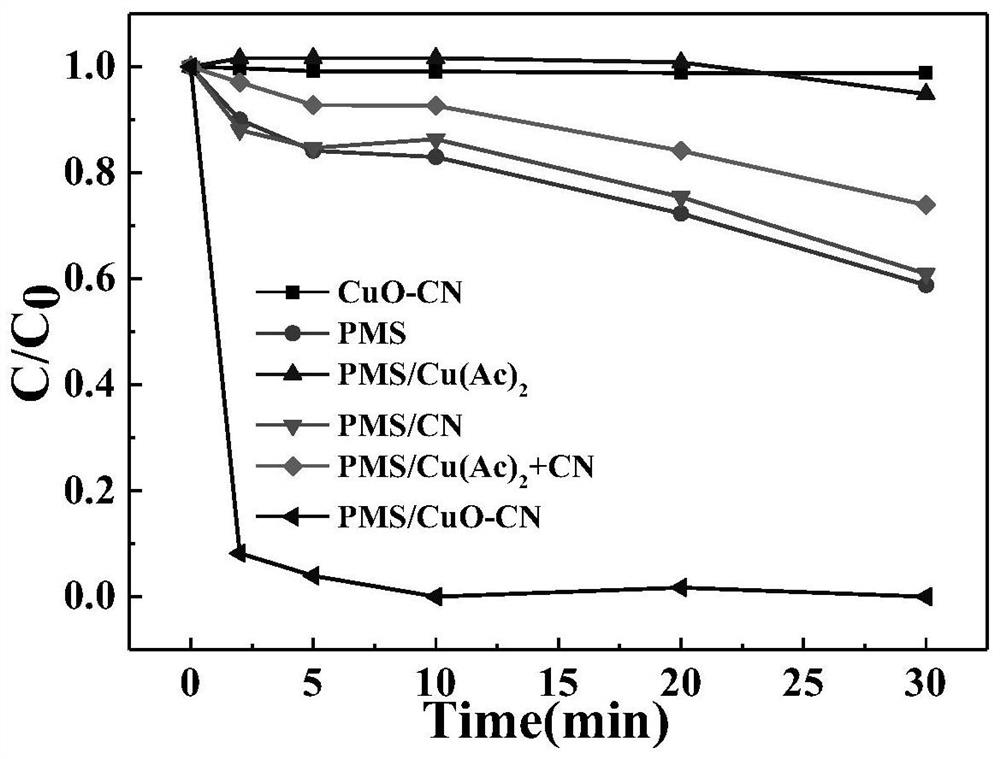

[0049] In this example, 7 sets of CuO-Cn peroxide composite catalysts prepared in Example 1 were used to catalyze PMS degradation DS, compared to the effect, including:

[0050] The aqueous solution of 50 ml of 5 mg / L dichlorofenac is model contaminant, the catalyst concentration is 0.5 g / L, and the oxidant (PMS) concentration is 50 mg / L. Sampling 0.5 mL within a given time interval, the contaminant content was detected using a high performance liquid chromatograph to evaluate the catalyst of the composite catalyst.

[0051] 7 sets of CuO-CN composite catalysts catalyze PMS degradation DS effect figure 2 Indicated. From figure 2 It can be seen that the degradation performance of the CuO-CN composite catalyst obtained when the amount of copper is added is 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com