Three-dimensional nitrogen-doped transition metal oxide/nickel sulfide composite catalyst and preparation method and application thereof

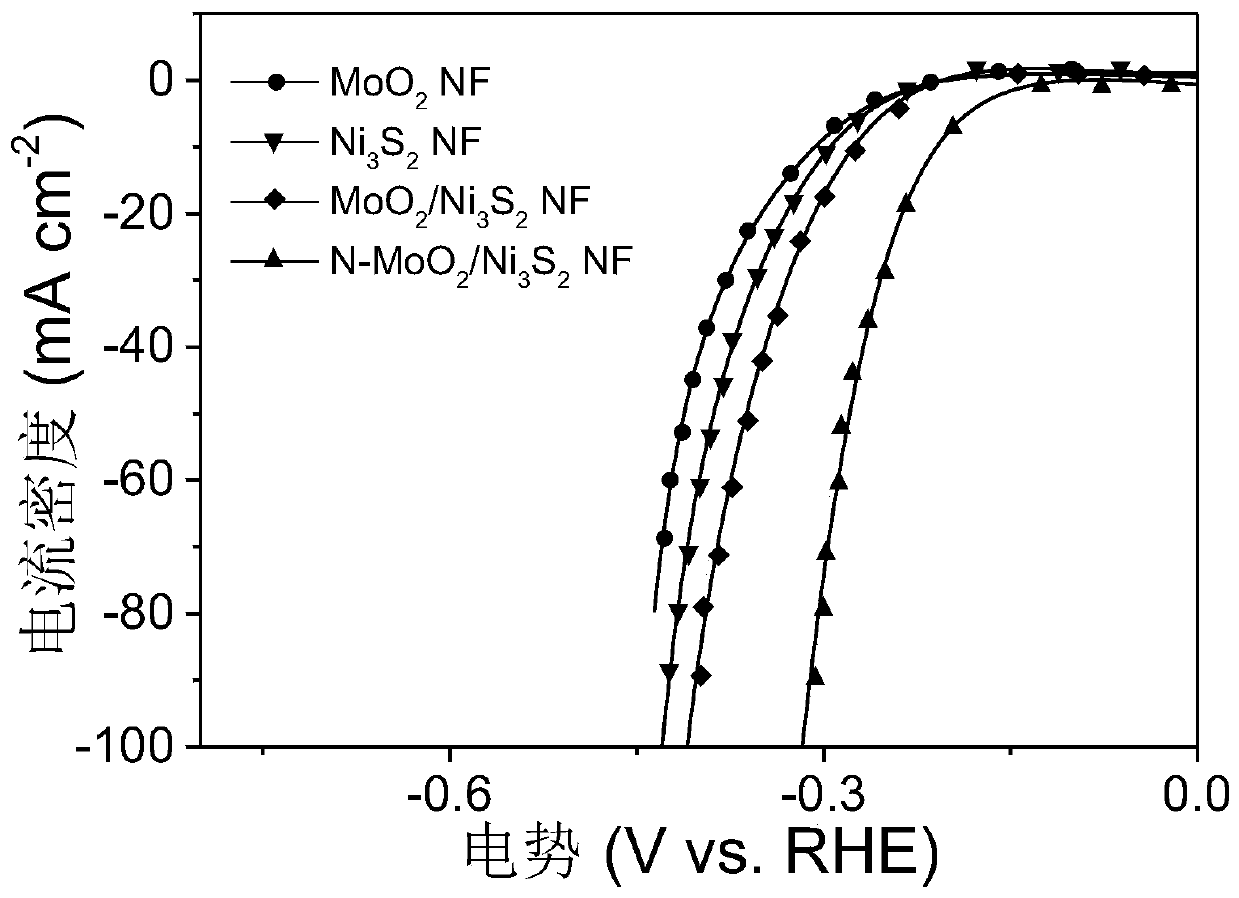

A composite catalyst, transition metal technology, used in physical/chemical process catalysts, chemical instruments and methods, electrolysis processes, etc., can solve problems such as difficult to meet industrial practical application standards, poor electrical conductivity, etc., and achieve high-efficiency electrocatalysis Activity and good stability, improved electrocatalytic activity, good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Preparation of ammonium tetrathiomolybdate solution

[0034] (1) Weigh 30 mg of ammonium tetrathiomolybdate solid particles, dissolve in 1 mL of aqueous solution, and sonicate for 10 min.

[0035] 2. Preparation of 1.0M KOH solution

[0036] (1) Measure about 50mL of ultrapure water and 5.61g of potassium hydroxide, dissolve them with ultrapure water and stir, after cooling, dilute to volume in a 100mL volumetric flask.

[0037] 3. Preparation of nickel ammonium tetrathiomolybdate foam precursor

[0038] (1) Put the nickel foam into the prepared ammonium tetrathiomolybdate solution and immerse it for 30 minutes;

[0039] (2) Dry naturally at room temperature for 24 hours.

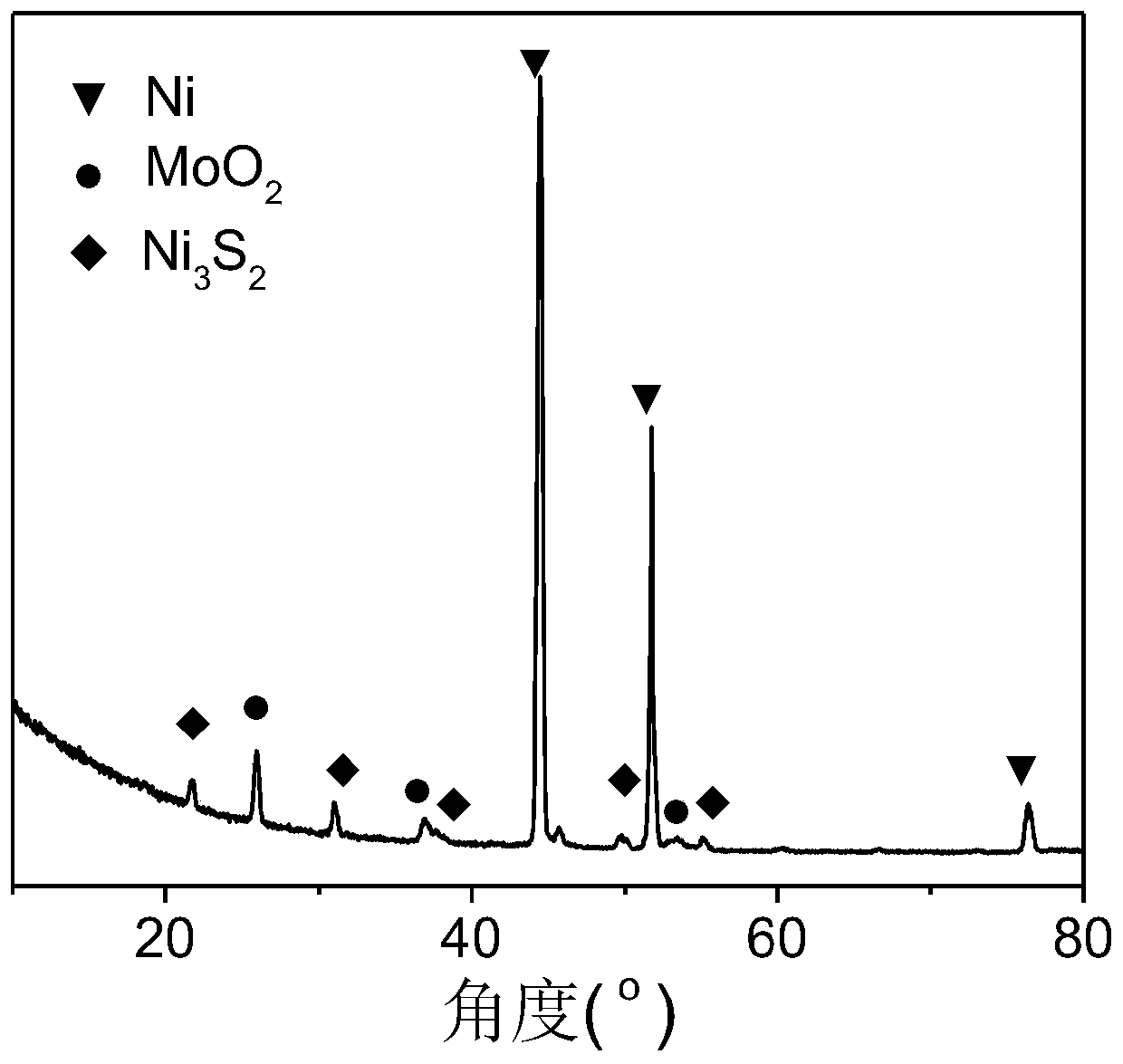

[0040] 4. MoO 2 / Ni 3 S 2 Preparation of NF catalyst

[0041] (1) The prepared nickel ammonium tetrathiomolybdate foam precursor was vacuum-sealed in a quartz sleeve, placed in a tube furnace for high-temperature calcination, and heated at 800°C for 3 hours;

[0042] (2) After the reaction i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com