A method for purifying and reusing methane-induced stable gas with high purity and high yield in the production of ethylene oxide by ethylene method

A technology of ethylene oxide and ethylene method, applied in chemical instruments and methods, separation methods, absorption purification/separation, etc., can solve problems such as poor stability and safety, low methane waste rate, rising energy consumption and production cost, etc. , to achieve the effect of safety, stability and economic benefits, low waste rate and load reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for purifying and reusing stable gas caused by high-purity and high-yield methane in the production of ethylene oxide by ethylene method, comprising the following steps:

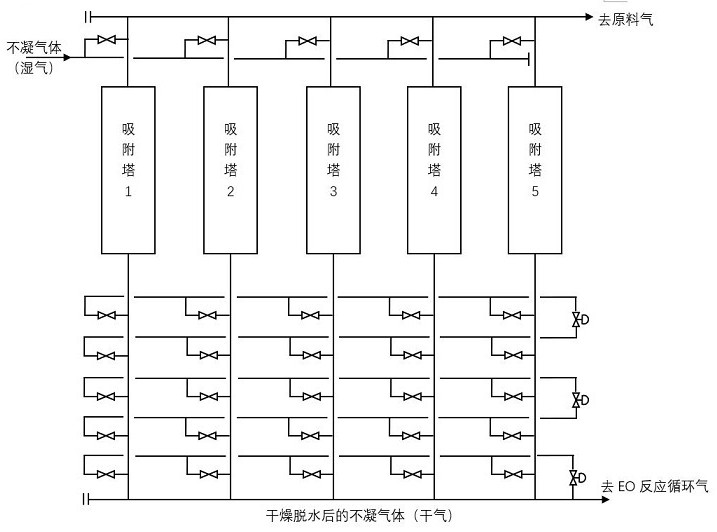

[0037] (1) Using commercial natural gas as raw material, its components are: methane (CH4) 94.18% (volume ratio, the same below), ethane (C2H6) 3.50%, propane (C3H8) 0.10%, butane (including isobutane Alkanes) 0.21%, carbon five carbon six alkanes (C5+) 0.14%, nitrogen (N2) 1.20%, carbon dioxide (CO2) 0.67%, water dew point -17.8 ℃, hydrogen sulfide 0.76mg / m3, oxygen (O2) 0.1%, The raw gas pressure is 50KPa, the temperature is normal temperature, and the flow rate is 2,500Nm3 / h. After being compressed by the compressor to 2.3MPa, it directly enters the PSA system with an operating temperature of 30°C and an operating pressure of 2.3MPa for decarburization and dehydration. The system consists of It is composed of 5 adsorption towers and corresponding pipelines, regulating valves and control va...

Embodiment 2

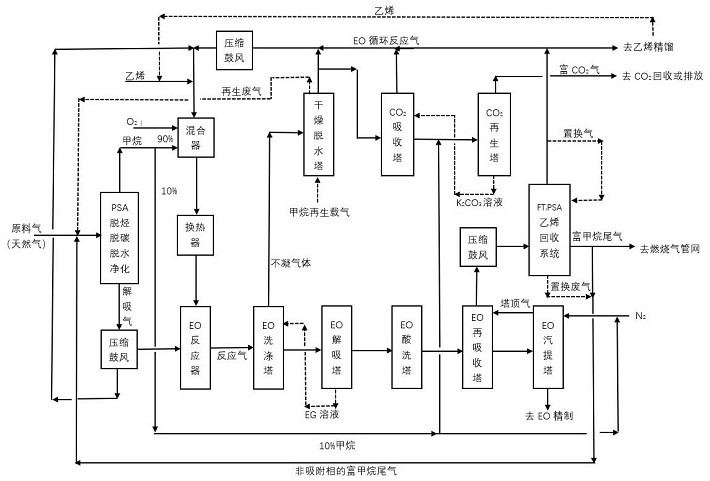

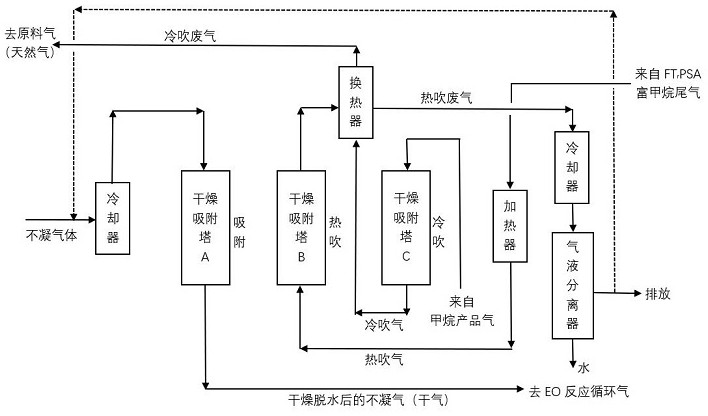

[0042] Based on Example 1, such as figure 1 As shown, industrial natural gas is used as the stabilizing gas in the process of preparing ethylene oxide by the ethylene method. Its main components are methane (CH4) 97.15% (volume ratio, the same below), ethane (C2H6) 0.50%, Propane (C3H8) 0.01%, butane (including isobutane) 0.02%, carbon five carbon six alkanes (C5+) 0.014%, nitrogen (N2) 0.76%, carbon dioxide (CO2) 1.4%, water dew point - 17.8°C, hydrogen sulfide 0.26mg / m3, oxygen + argon (O2+Ar) 0.006%, helium (He) 0.02%, raw material gas pressure 3.0MPa, temperature is normal temperature, the pressure required for EO reaction is the same as the example 1. The natural gas raw material is reduced to 2.3MPa after being regulated by a pressure regulating valve, and then enters the PSA system for decarburization, decarburization and dehydration, and the subsequent steps are the same as in Example 1.

Embodiment 3

[0044] Based on Examples 1 and 2, such as figure 1 As shown, the desorbed gas obtained from the PSA system in step (2) is blown and pressurized, and 40~50% of it enters the EO reaction cycle gas compressor for pressurization to the pressure required for the EO reaction of 2.2MPa and then returns directly To the ethylene oxide reaction cycle gas for reaction, most of the rest enters the regeneration tower for carbon dioxide absorption, and a small amount is directly sent to the fuel gas pipeline network, which will increase the load of the CO2 absorption system and increase the circulation of the thermal alkali absorbent. And the replacement gas volume of the FTrPSA system, the replacement gas is ethylene concentrated gas, and the concentration of ethylene is 85-90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com