Taxol freeze-dried powder preparation process and product

A preparation process and technology for paclitaxel, applied in freeze-drying delivery, powder delivery, drug combination and other directions, can solve the problems of large particle size and complex process of paclitaxel freeze-dried powder, avoid adverse reactions, simplify the preparation process, and achieve blood stability. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment (1-7

[0038] The preparation method of composition among the present invention comprises the following steps:

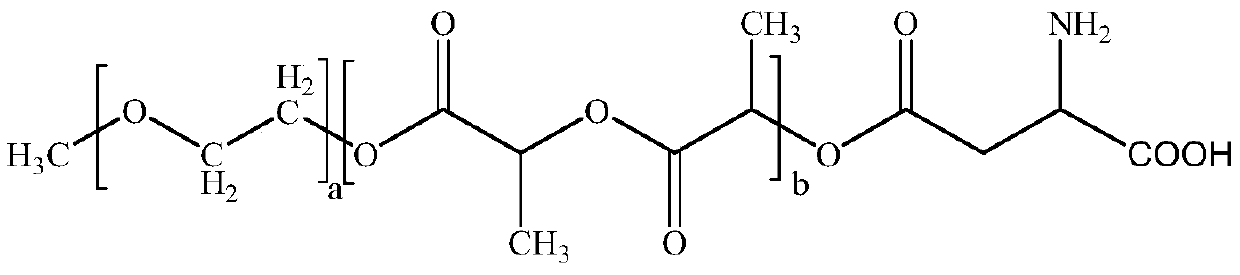

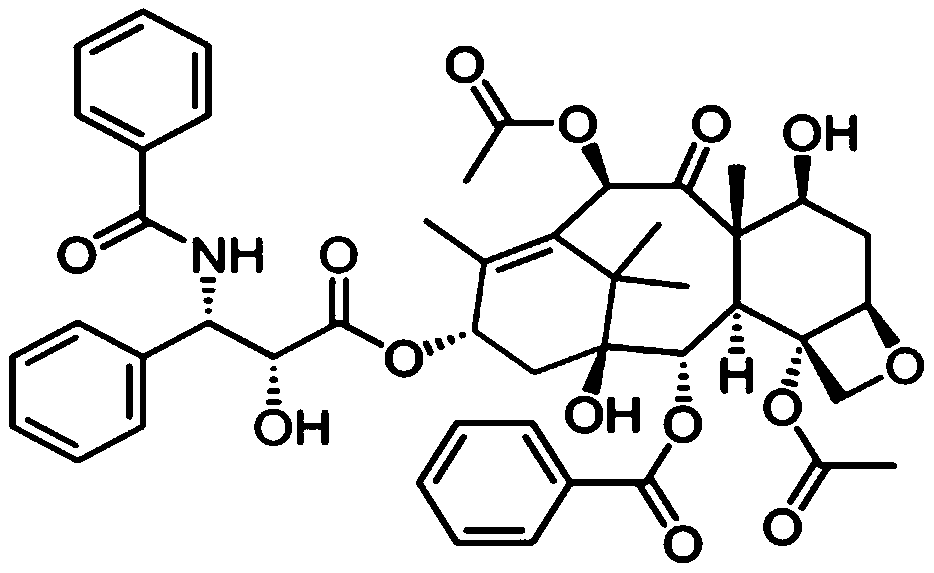

[0039] ①Weigh the raw materials (paclitaxel, mPEG-PLA-aspartic acid) according to different feeding ratios. Among them, paclitaxel (CAS33069-62-4) is produced by Xi'an Ruilin Biotechnology Co., Ltd., with a purity greater than 95%. preparation;

[0040] ②Put the above-mentioned raw materials into a container, and add organic solvents such as ethanol or acetonitrile at a temperature of 15-45°C until they are completely dissolved. The dissolving process can adopt means such as stirring or shaking.

[0041] ③ Rotate the above solution at 30-50°C for 2 hours until the organic solvent evaporates to dryness. Then vacuum drying at 10-40° C. for > 12 hours to remove residual organic solvents to obtain a paclitaxel-containing polymer mixed film.

[0042] ④ Place the above mixed membrane in a water bath at 40-60°C until it becomes transparent, add ultrapure water preheated at th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com