Fast and reliable combustion-supporting circuit of direct current magnetron sputtering coating power supply

A DC magnetron sputtering and control circuit technology, which is applied in the direction of converting AC power input to DC power output, electrical components, output power conversion devices, etc. High output voltage and other problems, to achieve the effect of reducing the output high-frequency rectification filter inductance and capacitance, filter inductance and filter capacitance reduction, inductance and capacitor energy storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

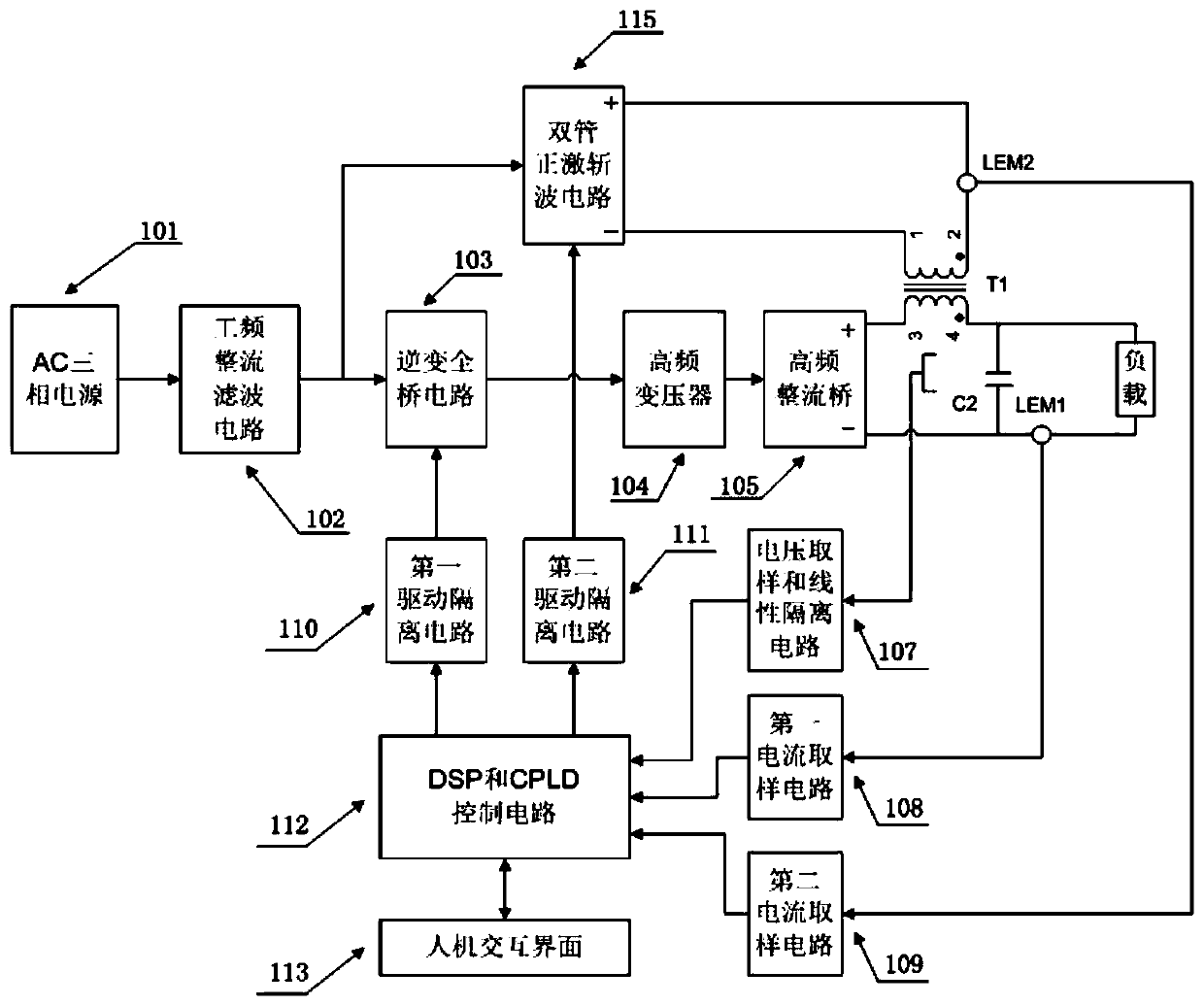

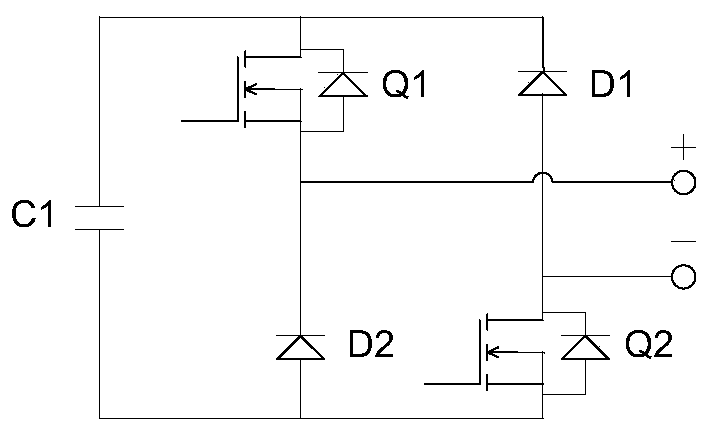

[0041] See figure 1 with figure 2 , The embodiment of the present invention provides a fast and reliable combustion-supporting circuit of a DC magnetron sputtering coating power supply, including: AC three-phase power supply 101, power frequency rectifier filter circuit 102, inverter full bridge circuit 103, high frequency transformer 104, double tube positive Exciting chopper circuit 115, high-frequency rectifier bridge 105, filter inductor T1 with two isolated windings, filter capacitor C2, DSP and CPLD control circuit 112, human-machine interface 113, Hall current sensor LEM1, Hall current sensor LEM2 , Voltage sampling and linear isolation circuit 107, first current sampling circuit 108, second current sampling circuit 109, first drive isolation circuit 110, second drive isolation circuit 111.

[0042] The output terminal of the AC three-phase po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com