Self-contained water-mixing coupling pressure-bearing efficient energy-saving furnace body

A high-efficiency, energy-saving, water-mixing technology, applied in water heaters, fluid heaters, household heating, etc., can solve problems such as poor circulation of the loop, failure to achieve the expected effect, damage to the boiler circulation pump, etc., to avoid heating Inertial temperature rise, quantity expansion, and the effect of improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

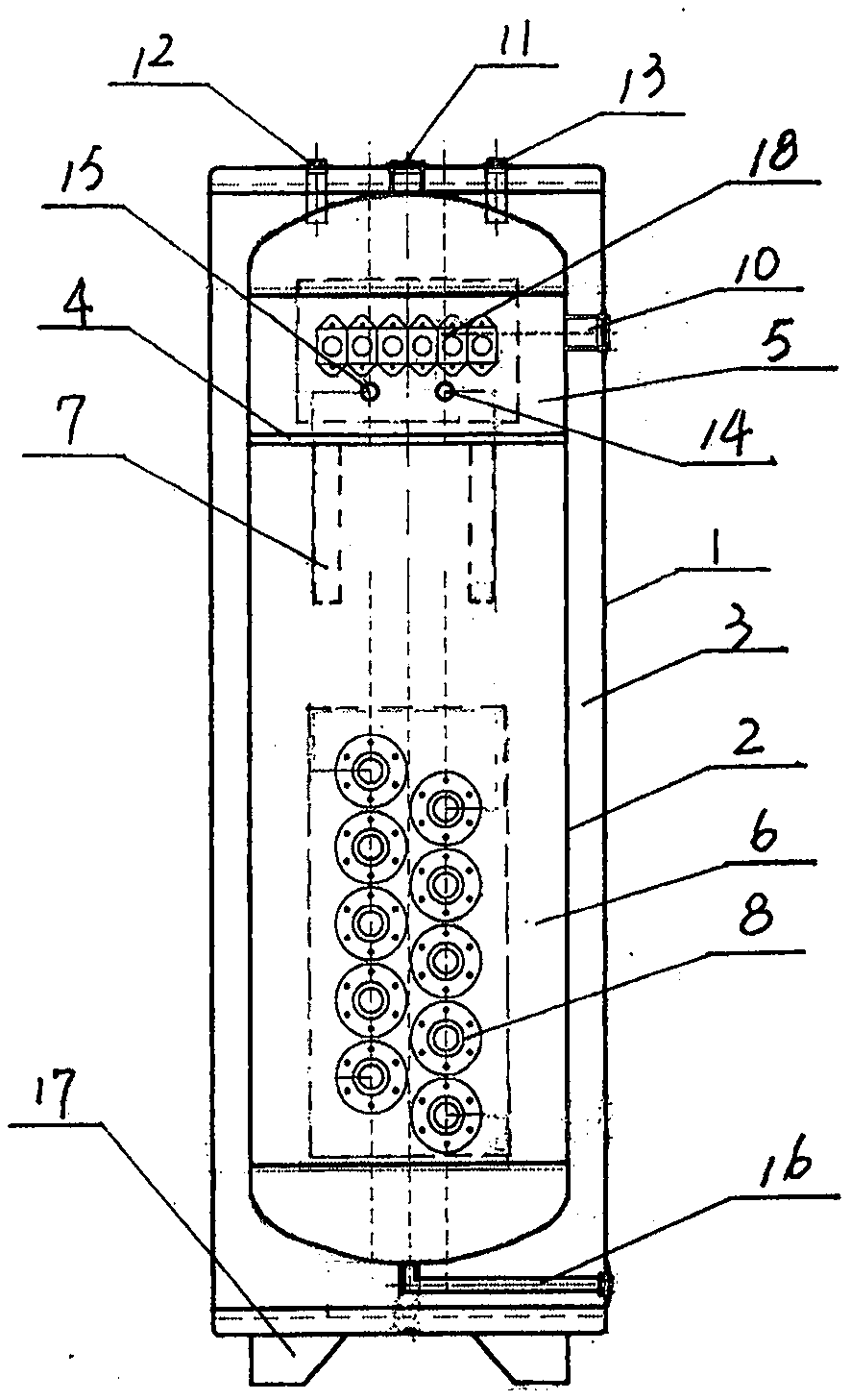

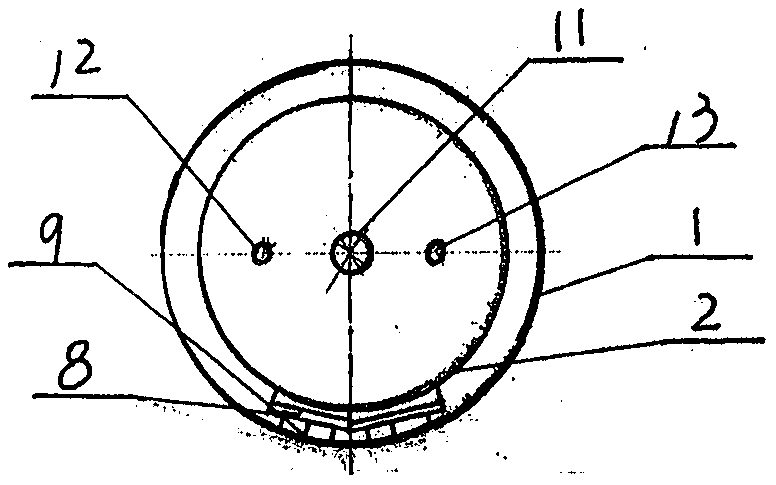

[0013] Such as figure 1 , figure 2 As shown, a stainless steel liner 2 with its own mixed-water coupling, pressure-bearing, high-efficiency and energy-saving furnace body is set in the shell 1, the insulation layer 3 is set in the middle of the shell 1 and the stainless steel liner 2, and the heating body 8 is fixedly arranged in the stainless steel liner 2. The front lower end of the heating chamber 6 in the lower part extends into the heating chamber 6 in parallel. The isolation plate 4 is arranged on the upper middle part of the stainless steel liner 2. The upper part of the isolation plate 4 is the mixing water coupling chamber 5, and the lower part is the heating chamber 6. Two The water-mixing coupling pipe 7 is equidistantly arranged at the lower end of the isolation plate 4 and connects the water-mixing coupling chamber 5 and the heating chamber 6. The return pipe 10 is arranged in the right middle part of the water-mixing coupling chamber 5, and the outlet pipe 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com