Photovoltaic plate surface cleaning device

A surface cleaning device, photovoltaic panel technology, applied in photovoltaic power generation, photovoltaic modules, cleaning methods and appliances, etc., can solve the problems of uneven operation force, waste of space resources, and many equipment failure points, and achieve a small rising height, guaranteed The effect of cleaning and improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

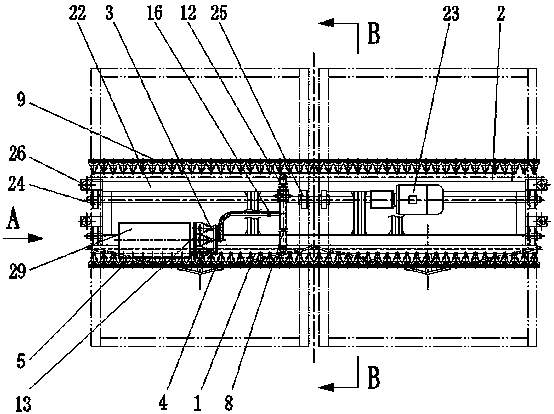

[0039] The cleaning device of the present invention can realize group-batch cleaning of user photovoltaic panels, and several photovoltaic panel monomers are arranged in a string (several single photovoltaic panels with a rectangular shape are arranged next to each other on a plane, arranged in a straight line In a group, called a string; often multiple strings of photovoltaic panels are arranged in one area) together, you can clean a single string together, or you can clean multiple strings together (attached figure 1 It is a schematic diagram of the layout of the two strings cleaning together); the cleaning device walks above the surface of the photovoltaic panel, and cleans the dust on the surface of the photovoltaic panel during the walking process.

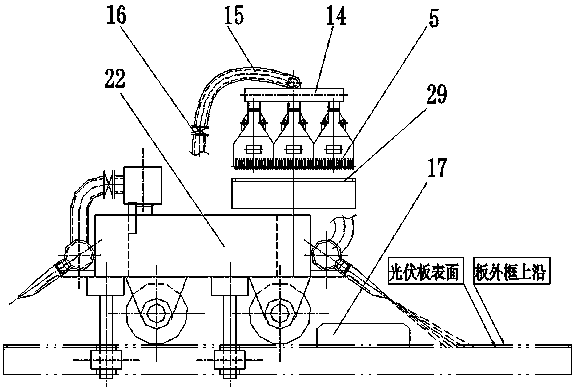

[0040] In the forward stage of the cleaning device, the front sweeping device 1 of the main blowing system is turned on, the blower starts to blow air, and it is sent to the front sweeping nozzle combination 5 of the front swe...

Embodiment 2

[0041] Embodiment 2: description of the equipment operation sequence of the cleaning device of the present invention

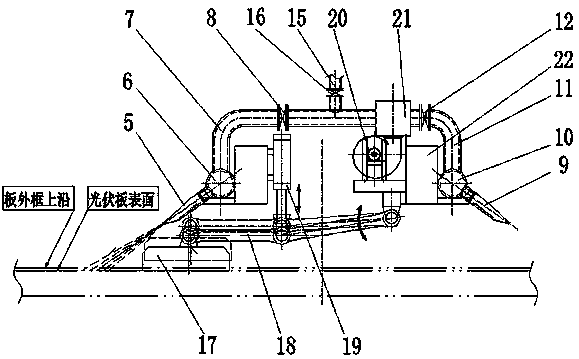

[0042] The working process of the cleaning device is as follows: before the cleaning work starts, the cleaning device is still at one end of the photovoltaic panel string arrangement area, that is, the starting position, waiting to receive the work start command. When the user's photovoltaic panel needs to be cleaned, the automatic control system sends a signal to the cleaning device, the auxiliary sweep control valve 16 on the auxiliary sweep air connection pipe 15 of the auxiliary blow system 3 is opened, and the two control valves of the air supply pipe of the main blow system (The front sweep control valve 8 and the back sweep control valve 12) are closed; the blast system is turned on, and the airflow generated is sent to the auxiliary purge system 3, and the airflow is blown by the auxiliary sweep nozzle combination 13 installed on the auxiliary purge sys...

Embodiment 3

[0047] Embodiment 3: detailed composition and working status description of the equipment of the present invention

[0048] (1) Main purge system

[0049] The main device used to clean the user's photovoltaic panel includes a set of front sweeping device 1 and a set of back sweeping device 2, which are installed on the front and rear of the trolley frame 22 respectively. The front sweeping device is used to purge the dust on the photovoltaic panel during the operation of the cleaning device from the initial position to the end position, and the back sweeping device is used to clean the photovoltaic panel during the operation of the cleaning device from the end position to the initial position. Clean the dust on it. The front sweeping device 1 is composed of the front sweep nozzle combination 5, the front sweep installation pipe 6, the front sweep air connection pipe 7, and the front sweep control valve 8; Between the installation pipes 6, a forward sweep control valve 8 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com