Distilling flask heating device and method which are capable of avoiding dry burning

A heating device and distillation bottle technology, applied in the field of distillation, can solve the problem of inability to monitor the distillation temperature of strong corrosive substances, and achieve the effects of not easy short-circuit damage, strong and uniform support, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

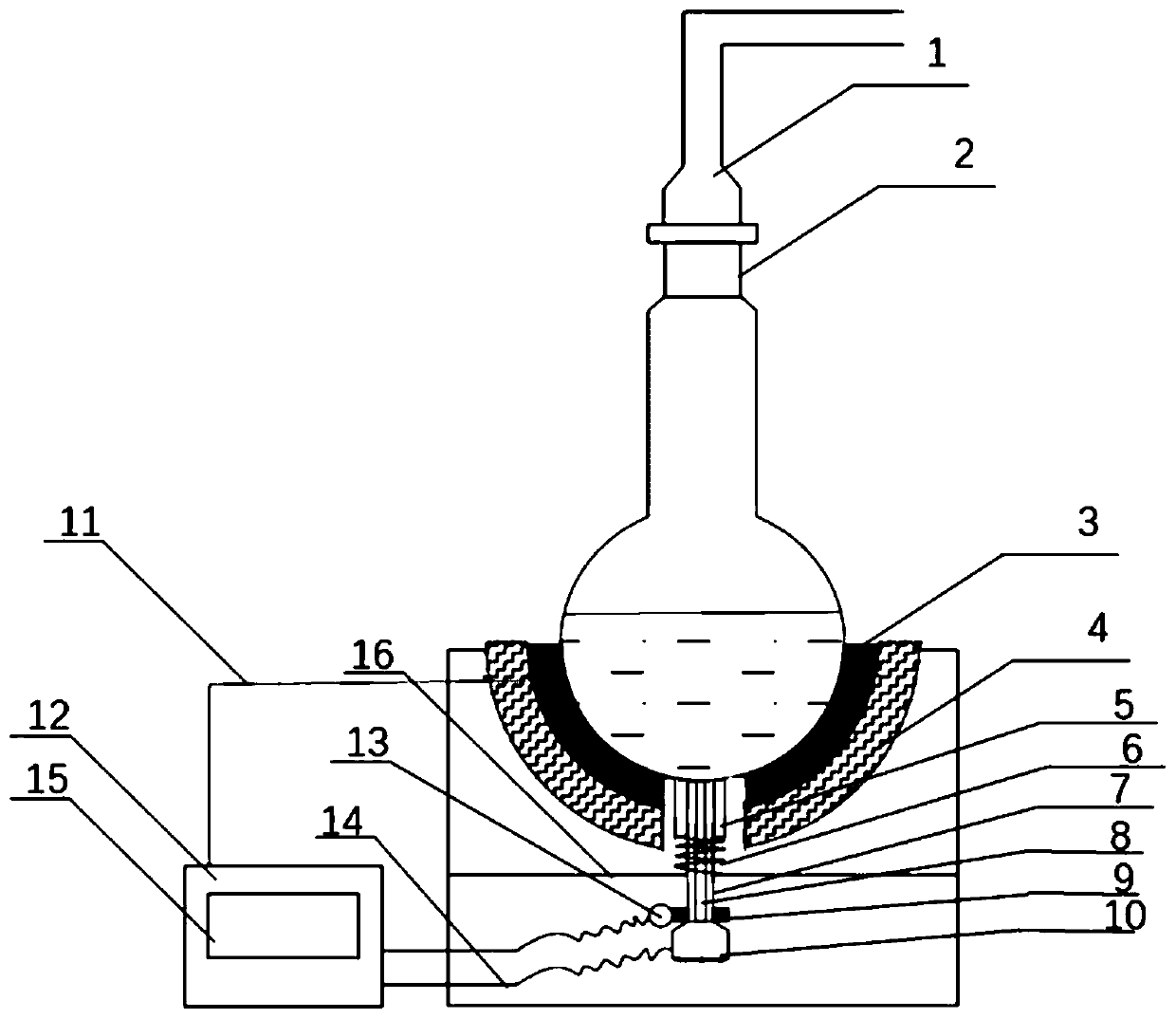

[0031] A heating device for anti-dry boiling retort, comprising a base and a heating jacket 3 arranged in the base, the heating jacket 3 forms a hemispherical cavity with an upward opening, the bottom of the heating jacket 3 is provided with a heating jacket through hole, and also includes infrared temperature measurement Unit and controller 12, the infrared temperature measurement unit is in contact with the bottom of the retort 2 through the through hole of the heating jacket, the controller 12 is electrically connected to the heating jacket 3 and the infrared temperature measurement unit respectively, and the infrared temperature measurement unit monitors the temperature of the retort 2 , and feed back to the controller 12, the controller 12 controls the heating process of the heating jacket 3.

[0032] The infrared temperature measurement unit includes a liner 7, an optical fiber 8 and an infrared temperature measurement probe 10. The optical fiber 8 is placed inside the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com