Underground diaphragm wall and construction method thereof

An underground continuous wall and connecting plate technology, applied in artificial islands, sheet pile walls, water conservancy projects, etc., can solve the problems of low anti-seepage performance, low structural strength and high engineering cost at joints, and ensure structural strength and anti-seepage. performance, improved strength and impermeability, the effect of high surface flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

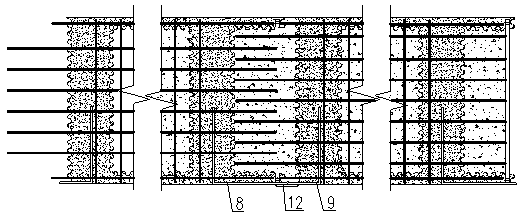

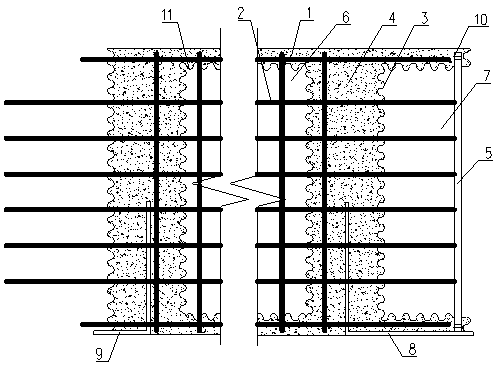

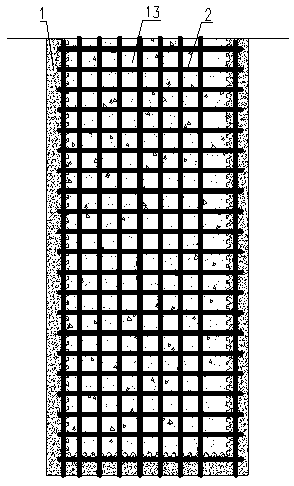

[0036] see Figure 1 to Figure 3 , the embodiment of the present invention provides an underground continuous wall, which includes several prefabricated wall units connected end to end in sequence, connecting plates 12 arranged between the outer sides of adjacent prefabricated wall units, and arranged on In-situ concrete 13 inside each prefabricated wall unit and between adjacent prefabricated wall units.

[0037] Further, the prefabricated wall unit includes a prefabricated concrete component 4, and a reinforcement cage 2 integrated with the prefabricated concrete component 4, which is fixedly connected with the reinforcement cage 2 respectively, is poured at both ends of the prefabricated concrete component 4 correspondingly, and is connected with the prefabricated concrete component 4 respectively. The first water-stop ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com