Carbon steel plate for seal head of middle and low temperature pressure vessel and manufacture method thereof

A technology for pressure vessels and manufacturing methods, which is applied in the field of steel plate manufacturing, can solve problems such as performance deterioration and coarse grains, and achieve the effects of good mechanical properties, low surface Brinell hardness, and low carbon equivalent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

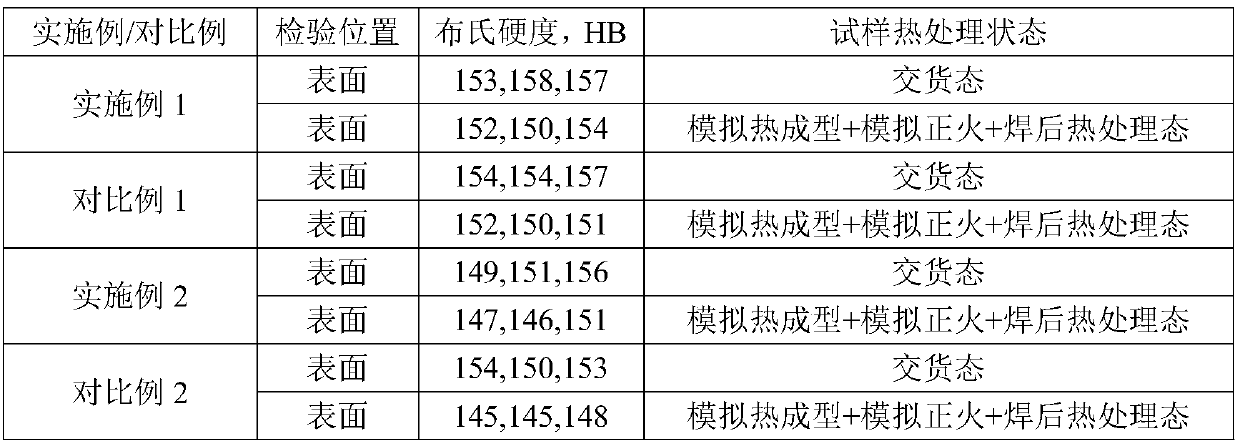

Examples

Embodiment 1

[0030] The thickness of the steel plate in this embodiment is 10mm, and its chemical composition is calculated by weight percentage: its chemical composition is calculated by weight percentage: C: 0.17%, Si: 0.36%, Mn: 1.25%, P: 0.006%, S: 0.001 %, Al: 0.035%, Nb: 0.018%, Ti: 0.012%, Ni: 0.22%, Cu: 0.20%, Ni / Cu; 1.1, the balance is Fe and unavoidable impurity elements, carbon equivalent Ceq: 0.424% , the manufacturing process of the steel plate is as follows:

[0031] The continuous casting slab with a section of 150mm is used as the billet. The main production process includes smelting process, heating process and rolling process. The rolling process adopts the normalizing rolling process. The specific operation of the main process is as follows:

[0032] 1) Smelting process

[0033] Smelting raw materials are sequentially subjected to KR molten iron pretreatment, converter smelting, LF refining, RH vacuum degassing treatment and slab continuous casting process. Slagging tr...

Embodiment 2

[0040] The thickness of the steel plate in this embodiment is 25mm, and its chemical composition is calculated by weight percentage: its chemical composition is calculated by weight percentage: C: 0.16%, Si: 0.36%, Mn: 1.28%, P: 0.007%, S: 0.001 %, Al: 0.030%, Nb: 0.016%, Ti: 0.015%, Ni: 0.26%, Cu: 0.22%, Ni / Cu; 1.18, the balance is Fe and unavoidable impurity elements, carbon equivalent Ceq: 0.425% , the manufacturing process of the steel plate is as follows:

[0041] The continuous casting slab with a section of 150mm is used as the billet. The main production process includes smelting process, heating process and rolling process. The rolling process adopts the normalizing rolling process. The specific operation of the main process is as follows:

[0042] 3) Smelting process

[0043] Smelting raw materials are sequentially subjected to KR molten iron pretreatment, converter smelting, LF refining, RH vacuum degassing treatment and slab continuous casting process. Slagging t...

Embodiment 3

[0050] The thickness of the steel plate in this embodiment is 40mm, and its chemical composition is calculated by weight percentage: its chemical composition is calculated by weight percentage: C: 0.17%, Si: 0.36%, Mn: 1.24%, P: 0.007%, S: 0.001 %, Al: 0.036%, Nb: 0.016%, Ti: 0.015%, Ni: 0.25%, Cu: 0.20%, Ni / Cu; 1.25, the balance is Fe and unavoidable impurity elements, carbon equivalent Ceq: 0.427% , the manufacturing process of the steel plate is as follows:

[0051] The continuous casting slab with a section of 150mm is used as the billet. The main production process includes smelting process, heating process and rolling process. The rolling process adopts the normalizing rolling process. The specific operation of the main process is as follows:

[0052] 5) Smelting process

[0053] Smelting raw materials are sequentially subjected to KR molten iron pretreatment, converter smelting, LF refining, RH vacuum degassing treatment and slab continuous casting process. Slagging t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com