Freeze-drying protecting agent for improving normal temperature preservation and anti-pressure ability of lactobacillus bulgaricus and application of freeze-drying protecting agent

A freeze-drying protective agent, a technology for preservation at room temperature, applied in the directions of bacteria, preservation of microorganisms, microorganism-based methods, etc., can solve problems such as poor tolerance of Lactobacillus bulgaricus, achieve freeze-drying process optimization, improve stress resistance, and reduce production. and cost of sales

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1. The preparation of lyoprotectant and lyophilized bacterial powder

[0017] The components of the freeze-drying protective agent are respectively by weight: 100 parts of pregelatinized starch, 50 parts of skimmed milk powder, 80 parts of maltodextrin, 20 parts of trehalose, and 750 parts of sterile distilled water.

[0018] The preparation process of freeze-dried bacterial powder comprises the following steps: after the Lactobacillus bulgaricus is activated, carry out step-by-step amplified fermentation culture according to the inoculum size of 5-10% (v / v), collect the thalline by centrifugation, and follow the bacteria slime: frozen The dry protectant is fully mixed at a weight ratio of 1:2 to make a freeze-dried upper machine solution. Pour the freeze-dried supernatant liquid into the freeze-drying tray, the thickness of the supernatant liquid is controlled at 1.5 cm, and put it into the freeze dryer at -40°C for 6 hours for pre-freezing. During the dryi...

Embodiment 2

[0019] Embodiment 2. The preparation of lyoprotectant and lyophilized bacterial powder

[0020] The components of the freeze-drying protective agent are respectively by weight: 120 parts of pregelatinized starch, 60 parts of skimmed milk powder, 80 parts of maltodextrin, 40 parts of trehalose, and 700 parts of sterile distilled water.

[0021] The preparation process of freeze-dried bacterial powder comprises the following steps: after the Lactobacillus bulgaricus is activated, carry out step-by-step amplified fermentation culture according to the inoculum size of 5-10% (v / v), collect the thalline by centrifugation, and follow the bacteria slime: frozen The dry protectant is fully mixed at a weight ratio of 1:3 to make a freeze-dried supernatant. Pour the freeze-dried supernatant liquid into the freeze-drying tray, the thickness of the supernatant liquid is controlled at 1.5cm, and pre-freeze in the freeze dryer at -40°C for 4-8h. During the drying process, the vacuum degree ...

Embodiment 3

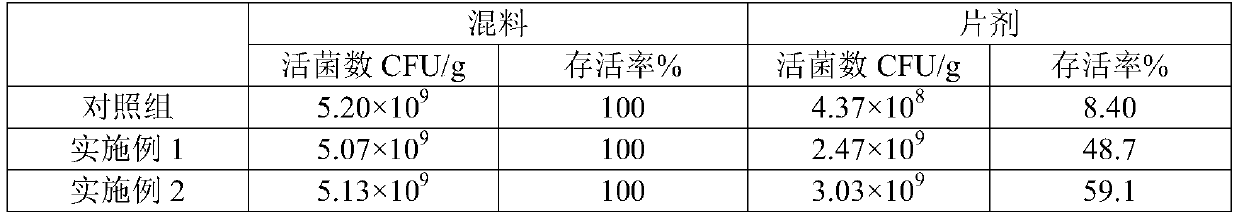

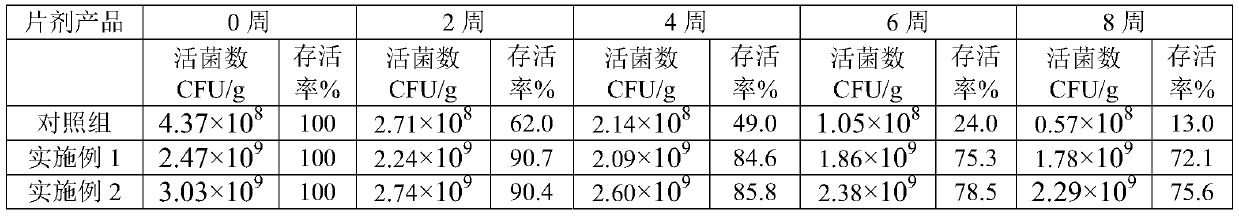

[0022] Embodiment 3. Lactobacillus bulgaricus bacteria powder room temperature storage stability test

[0023] Taking the Lactobacillus bulgaricus bacterial powder prepared by the existing bacterial powder production process as a contrast, its freeze-drying protective agent composition: 180 parts of skimmed milk powder, 60 parts of lactose, 60 parts of yeast powder, and 700 parts of sterile distilled water; freeze-drying process: drying The vacuum degree of the process is always controlled between 0.2mbar, the pre-freezing temperature is -60°C, the pre-freezing time is 10h, and the temperature is raised to 0°C at a rate of 4°C / h during the first drying process. During the analytical drying process, the temperature was raised from 0°C to 25°C at a rate of 2°C / h and maintained for 3h.

[0024] Investigate the stability of the bacteria powder prepared in Examples 1 and 2 stored at 25°C for 8 weeks. Its test result (table 1) shows, compares with control group, the normal temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com