A two-component water blocking reinforcement grouting material and its preparation method

A grouting material and two-component technology are applied in the field of two-component water blocking reinforcement grouting materials and their preparation, which can solve the problems of poor adhesion of polyurethane grouting materials on wet foundations, the reaction speed is greatly affected by temperature, and the performance cannot be taken into account. , to improve the effect of plugging and reinforcement, good toughness and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

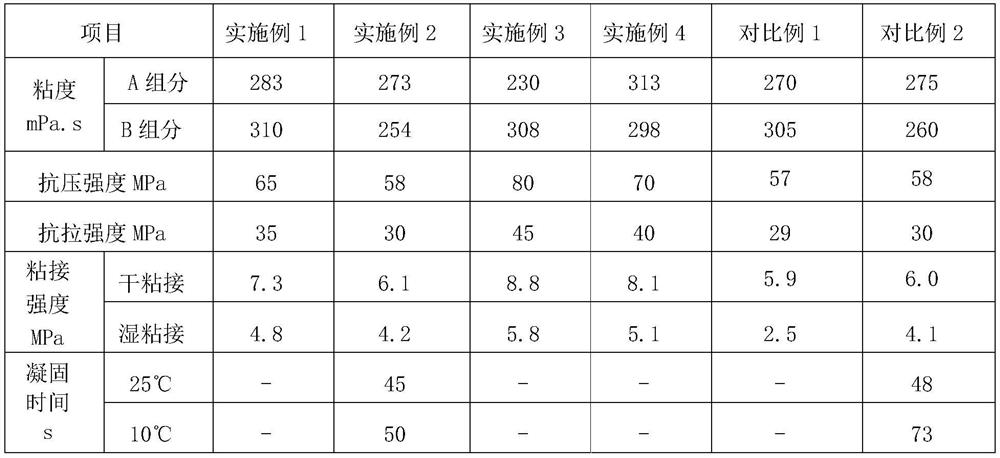

Examples

preparation example Construction

[0033] Another aspect of the present invention provides the preparation method of the above-mentioned two-component water blocking reinforcement grouting material, the preparation method comprising:

[0034] Preparation of component A: dehydrate polyether polyol, polyester polyol and optional plasticizer, cool down, and then mix with latent curing agent, foam stabilizer and catalyst;

[0035] Preparation of component B: prepare measured polyisocyanate.

[0036] According to the present invention, preferably, the dehydration is: dehydration at a temperature of 110-120°C and a vacuum of -0.09 to -0.1MPa for 2-3 hours until the moisture content is less than 0.05wt%; Below 40°C.

Embodiment 1

[0044] This embodiment provides a two-component water blocking reinforcement grouting material, including: A component and B component,

[0045] The A component includes: 45 parts by weight of polyether polyol MN-500 (hydroxyl value: 340; polyether trihydric alcohol), 35 parts by weight of polyester polyol HF-8725 (hydroxyl value: 240), 1.5 parts by weight Parts of amine catalyst DMDEE (dimorpholino diethyl ether), 0.8 parts by weight of metal catalyst T12, 2 parts by weight of latent curing agent ALT-101 (oxazolidine latent curing agent), 1.5 parts by weight of foam stabilizer AK- 8803, 14.2 parts by weight of plasticizer diisononyl phthalate;

[0046] The B component includes: 65 parts by weight of polyphenyl polymethylene polyisocyanate.

[0047] The present embodiment also provides the preparation method of above-mentioned grouting material, comprises the following steps:

[0048] Preparation of component A: Dehydrate polyether polyol, polyester polyol and plasticizer at a...

Embodiment 2

[0052] This embodiment provides a two-component water blocking reinforcement grouting material, including: A component and B component,

[0053] The A component includes: 40 parts by weight of polyether polyol DL-1000 (hydroxyl value: 56; polyether diol), 40 parts by weight of polyester polyol FH-8040 (hydroxyl value: 400), 1 part by weight Amine catalyst 12-DMA (dodecyl dimethyl tertiary amine), 1 weight part metal catalyst bismuth isooctanoate, 2 weight parts foam stabilizer AK-8876, 3 weight parts latent curing agent ALT-401 (oxazolidine class latent curing agent) and the plasticizer phenyl sulfonate of 13 parts by weight;

[0054] The B component includes: 30 parts by weight of polyphenyl polymethylene polyisocyanate and 20 parts by weight of MDI-50.

[0055] The present embodiment also provides the preparation method of above-mentioned grouting material, comprises the following steps:

[0056] Preparation of component A: dehydrate polyether polyol, polyester polyol and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com