A low-pressure dimethyldichlorosilane hydrolysis system and process

A dimethyldichlorosilane and process technology, which is applied in the field of low-pressure dimethyldichlorosilane hydrolysis system, can solve the problem of incomplete reaction of dimethyldichlorosilane, complicated setting of purification and washing system, increased investment and operating costs and other problems, to achieve the effect of less impurities, uniform chain length and lower acidity value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

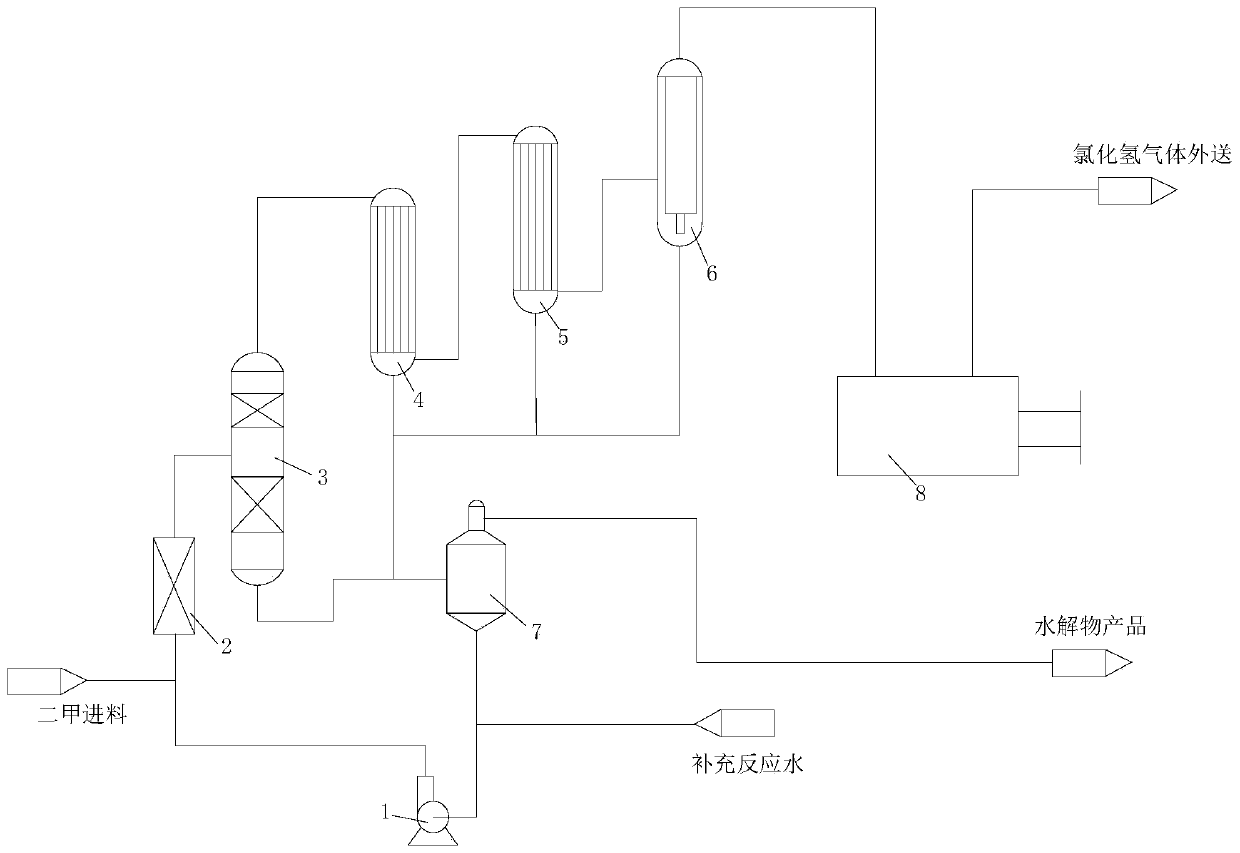

[0049] A low-pressure system for the hydrolysis of dimethyldichlorosilane, such as figure 1 As shown, a circulation pump 1, a hydrolysis reactor 2, a desorption tower 3, a condenser 4, a dryer 5, a mist eliminator 6, a separator 7 and a compressor pump 8 are included.

[0050] The hydrolysis reactor 2, the hydrolysis reactor is a tubular structure, a number of mixing blades are installed in the tubular structure, and the tubular structure is filled with fillers. Flower plates are arranged at both ends of the tubular structure, the flower plates are perpendicular to the axis of the tubular structure, and the flower plates are plate-shaped structures with several through holes.

[0051] The hydrochloric acid solution is used as the carrier of the reaction, which is pressurized by the circulation pump 1 and mixed with dimethyldichlorosilane in the pipeline, then enters the hydrolysis reactor 2, and quickly mixes in the hydrolysis reactor 2, and after the hydrolysis reactor 2 ente...

Embodiment 2

[0055] The system of this embodiment is the same as that of Embodiment 1.

[0056] The specific process parameters are:

[0057] The feed rate of dimethylformamide is 1 liter / hour, the circulation rate of hydrochloric acid is 3 liters / hour, and the concentration of hydrochloric acid is 35%. During the test reaction process, the pressure was controlled at about 50KPa, the reaction temperature was controlled at about 45°C, the oil phase of the reaction product stayed in the separator for about 3 minutes, and stood still for 5 minutes after separation. At this time, the loop ratio of the hydrolyzate was measured by laboratory analysis. : 49, the acidity content in the hydrolyzate is 0.5% (saturated acid hydrolysis is generally more than 3%).

Embodiment 3

[0059] The system of this embodiment is the same as that of Embodiment 1.

[0060] The specific process parameters are:

[0061] The feed rate of dimethylformamide is 1 liter / hour, the circulation rate of hydrochloric acid is 5 liters / hour, and the concentration of hydrochloric acid is 33%. During the test reaction, the pressure was controlled at about 30KPa, the reaction temperature was controlled at about 45°C, the oil phase of the reaction product stayed in the separator for about 3 minutes, and stood still for 5 minutes after separation. At this time, the loop ratio of the hydrolyzate was measured by laboratory analysis. : 42, the acidity content in the hydrolyzate is 0.65% (saturated acid hydrolysis is generally more than 3%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com