A kind of heterogeneous Fenton catalyst of nano-rod-shaped bismuth-doped molybdenum sulfide sphere and its preparation method and application

A nanorod-like catalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of energy waste, waste of resources, low utilization rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

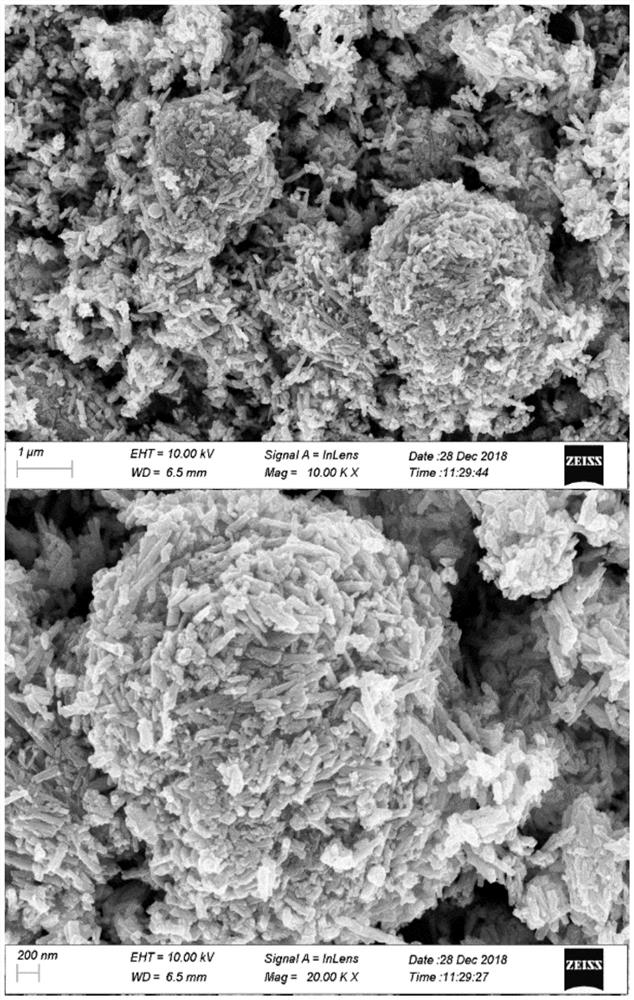

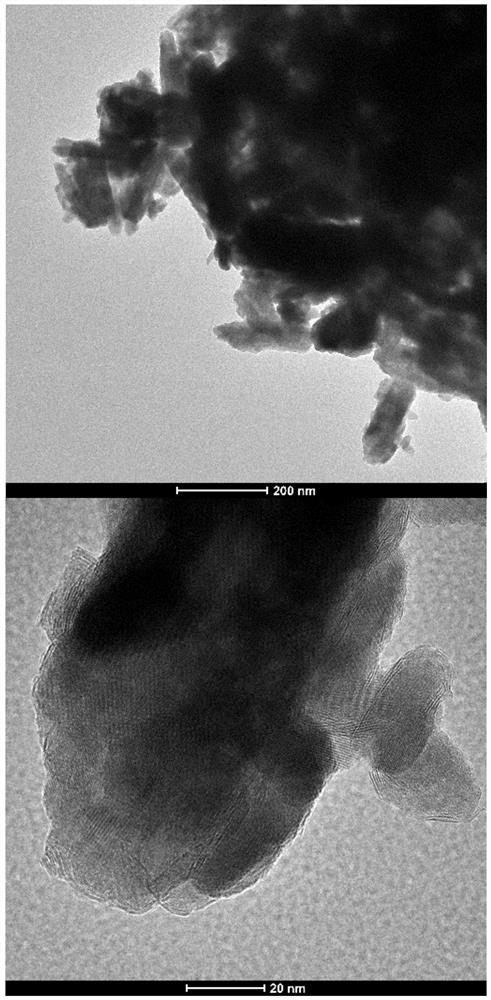

[0040] A nanorod-shaped bismuth-doped molybdenum sulfide sphere heterogeneous Fenton catalyst (CN-Bi-MoS 2 ) preparation method, said method comprising the following steps:

[0041] (1) 4.85g of Bi(NO 3 ) 3 ·5H 2 O, 1.77g of (NH 4 ) 6 Mo 7 o 24 4H 2 O and 3.78g CH 4 N 2 S was added to 180ml of deionized water, stirred at 45°C for 30 minutes and mixed to obtain mixed system A; then ultrasonically treated at 45°C for 30 minutes, and then stirred at 45°C for 30 minutes to obtain mixed system A;

[0042] (2) Transfer the mixed system A to an autoclave, and conduct a hydrothermal reaction at 200° C. for 24 hours to obtain the mixed system B;

[0043](3) Alternately washing the mixed system B with deionized water and absolute ethanol, drying at 60-100° C. for 4-20 h, and grinding to obtain the nanorod-shaped bismuth-doped molybdenum sulfide sphere heterogeneous Fenton catalyst.

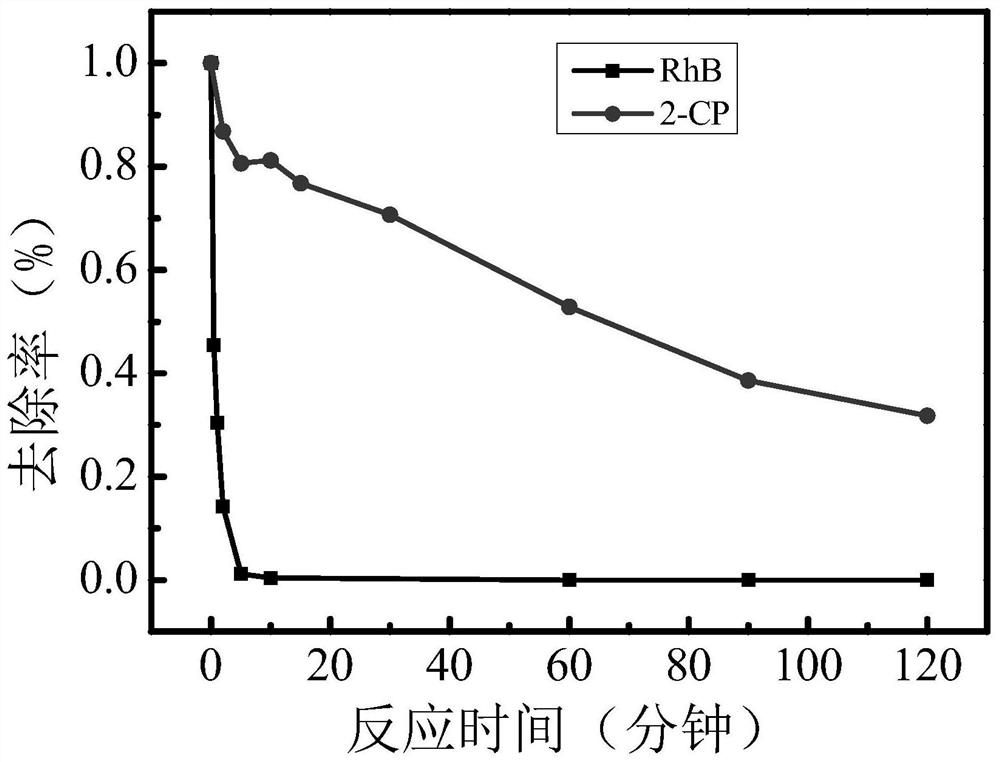

[0044] The nano-rod-shaped bismuth-doped molybdenum sulfide sphere heterogeneous Fenton catal...

Embodiment 2

[0047] As a preparation method of a nanorod-shaped bismuth-doped molybdenum sulfide sphere heterogeneous Fenton catalyst in Example 1 of the present invention, the only difference between this example and the example is: the temperature of the hydrothermal reaction in step (2) is 180°C .

Embodiment 3

[0049] As a method for preparing a nanorod-shaped bismuth-doped molybdenum sulfide sphere heterogeneous Fenton catalyst in Example 1 of the present invention, the only difference between this example and the example is: the temperature of the hydrothermal reaction in step (2) is 220°C .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com