Magnetic evaluation method for irradiation accelerated stress corrosion cracking sensitivity of austenitic stainless steel

An austenitic stainless steel, corrosion cracking technology, applied in the direction of material magnetic variables, preparation of test samples, etc., can solve the problem of inability to obtain ion irradiation samples IASCC sensitivity, unfavorable test work development, tensile sample materials There are many other problems to achieve the effect of fast test speed, simple test and small human factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

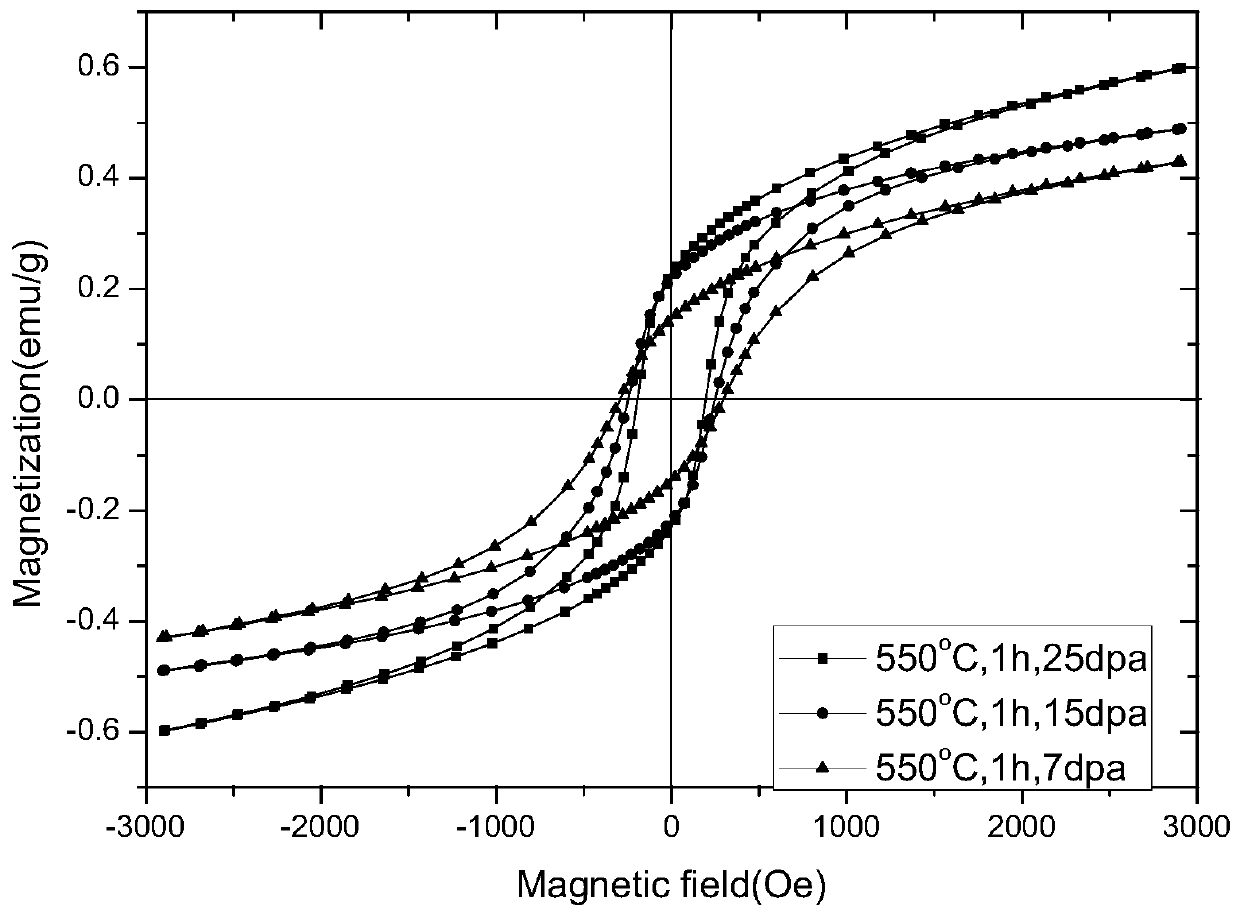

[0067] In order to evaluate the radiation-accelerated stress corrosion cracking susceptibility of an austenitic stainless steel at room temperature after irradiation to 7dpa, 15dpa and 25dpa, the following steps are used for evaluation:

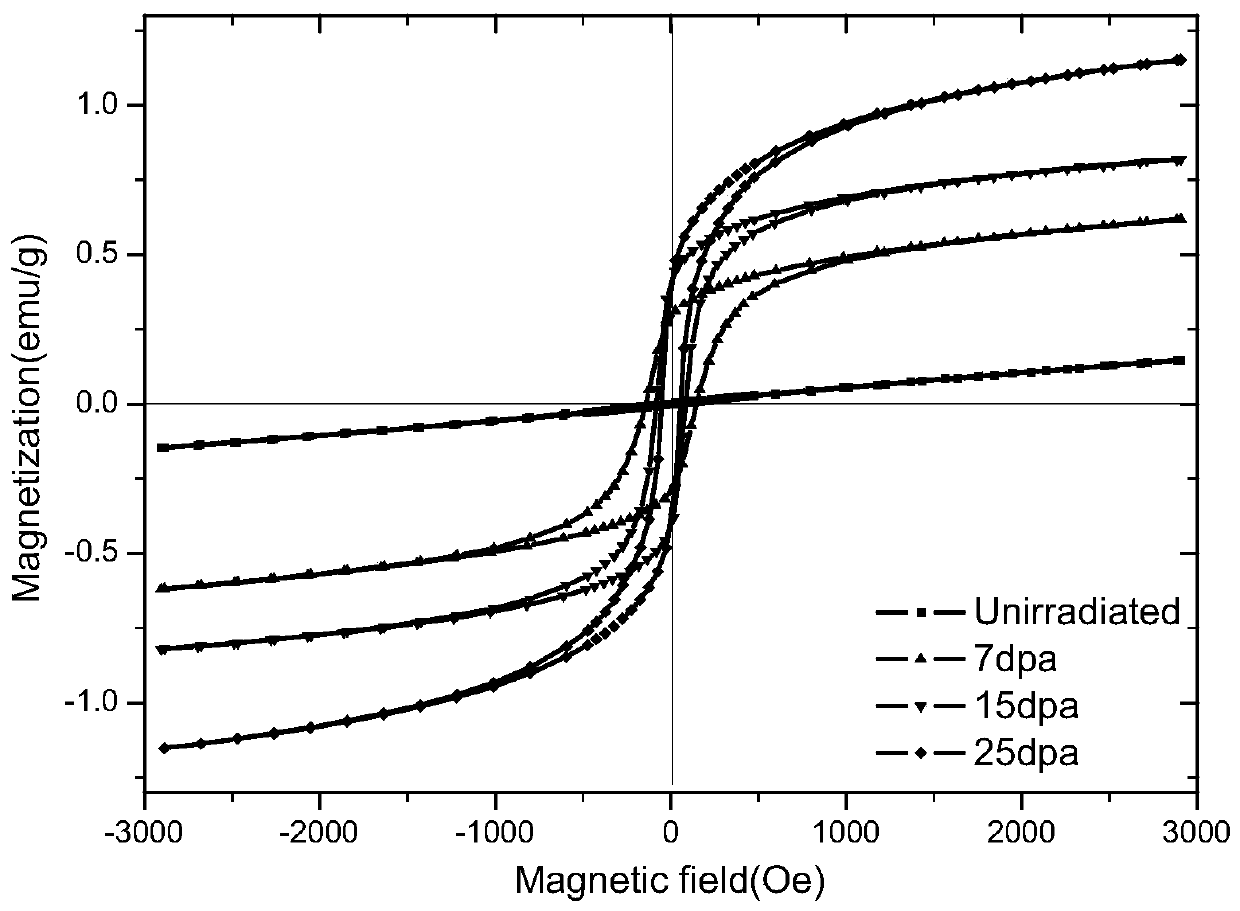

[0068] (1) Measure and record the M-H curve of the initial sample of austenitic stainless steel to be evaluated, the results are as follows figure 1 shown. Depend on figure 1 It can be seen that M and H of the initial sample of austenitic stainless steel have a linear relationship, which conforms to M(H)=χ p H relationship, and χ p =4.9×10 -3 , applicable to this IASCC sensitivity assessment method.

[0069] (2) Process the initial sample of austenitic stainless steel into a diameter of d=3mm and a thickness of L 0 = 25μm disc as the test sample; after the processing is completed, measure the M-H curve of the test sample again to obtain the processed χ p =4.9×10 -3 , indicating that the processing of the sample does not introduce addi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com