Device dedicated to soy sauce stirring

A soy sauce and mixing chamber technology, applied in biochemical cleaning devices, enzymology/microbiology devices, bioreactors/fermentation tanks for specific purposes, etc., can solve the problem of soy sauce raw materials entering the shell through the feed pipe when the device is working After the mixing chamber, the motor works, the driving worm drives the turbine to rotate, and then drives the connecting shaft to rotate, so that the stirring device starts to work, and the soy sauce raw materials are stirred, and the soy sauce stirred by the stirring device enters the coil a in the sterilization chamber , prolong the storage time of soy sauce, and the large dispersion range of soy sauce, so as to improve the flavor of soy sauce, improve the purity of soy sauce, and avoid the dispersion of soy sauce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

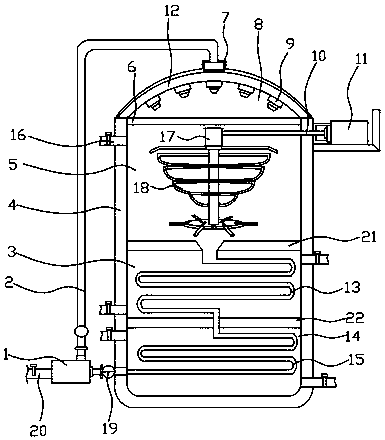

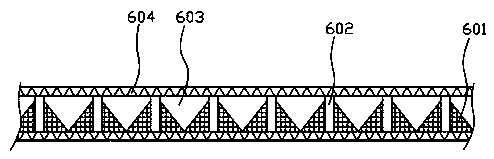

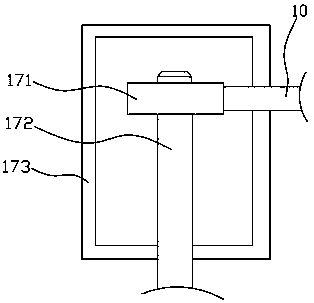

[0026] like Figure 1-6As shown, the device dedicated to soy sauce stirring includes a housing 4, and the inside of the housing 4 is sequentially provided with a spray chamber 8, a stirring chamber 5, a sterilization chamber 3, a cooling chamber 14, a spray chamber 8, a stirring chamber The chamber 5, the sterilization chamber 3, and the cooling chamber 14 are separated from each other by the filter screen 6, the partition a21, and the partition b22 respectively; Bars 604, gear rods 602 are arranged at equal intervals in the filter cavity 603, and right-angled filter screens 601 are arranged on the left and right sides of the gear rod 602. When the device works, after the soy sauce raw material enters the mixing chamber 5 in the housing 4 through the feed pipe 16, the motor 11 works, the driving worm 10 drives the turbine 171 to rotate, and then drives the connecting shaft 172 to rotate, so that the stirring device 18 starts to work, and the soy sauce The raw materials are st...

Embodiment 2

[0037] When the device of the present invention is specially used for stirring soy sauce in actual use: when the device is working, after the soy sauce enters the mixing chamber 5 in the housing 4 through the feed pipe 16, the motor 11 works, and the driving worm 10 drives the turbine 171 to rotate, and then drives the connection The shaft 172 rotates to make the stirring device 18 start to work, and stirs the soy sauce raw materials. The soy sauce stirred by the stirring device 18 enters the coil a13 in the sterilization chamber 3, and after the heating treatment, the materials are mixed more evenly Sterilizing the soy sauce is beneficial to prolong the storage time of the soy sauce, make the soy sauce ferment thoroughly, and improve the flavor of the soy sauce. The sterilized soy sauce then enters the coil b15 in the cooling chamber 14 for cooling treatment. After the cooling treatment, it is beneficial to the soy sauce While the next production link is running smoothly, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com