A method for extracting high-purity metallothionein from mantis shrimp

A technology for metallothionein and mantis shrimp, which is applied in the field of extracting high-purity metallothionein from mantis shrimp, can solve the problems of harsh extraction objects, long extraction period, short extraction period and the like, and achieves low cost and extraction period. Short, low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Shrimp shells are removed, the edible part is taken, and Tris-HCl buffer solution with a pH of 7.8 and a concentration of 0.02mol / L is added at a liquid-to-material ratio of 4:1, stirred and extracted in a water bath at 51°C for 1 hour, and the extract Refrigerate and centrifuge at 4°C and 13000r / min for 25min at high speed, discard the precipitate; collect the supernatant a and heat it in a water bath at 80°C for 5min to remove thermally unstable macromolecular proteins. Centrifuge at 1 / min for 25 min; after collecting the supernatant b, add 3 times the volume of pre-cooled (temperature 4°C) absolute ethanol, and precipitate overnight at -20°C. After centrifugation at 4°C and 13000r / min for 25min, take the precipitate and add 2-3mL ultrapure water to fully dissolve it, then centrifuge at 4°C, collect the supernatant c and store it at -18°C to obtain Mantis shrimp metallothionein crude extract, referred to as crude extract MT freeze-dried powder;

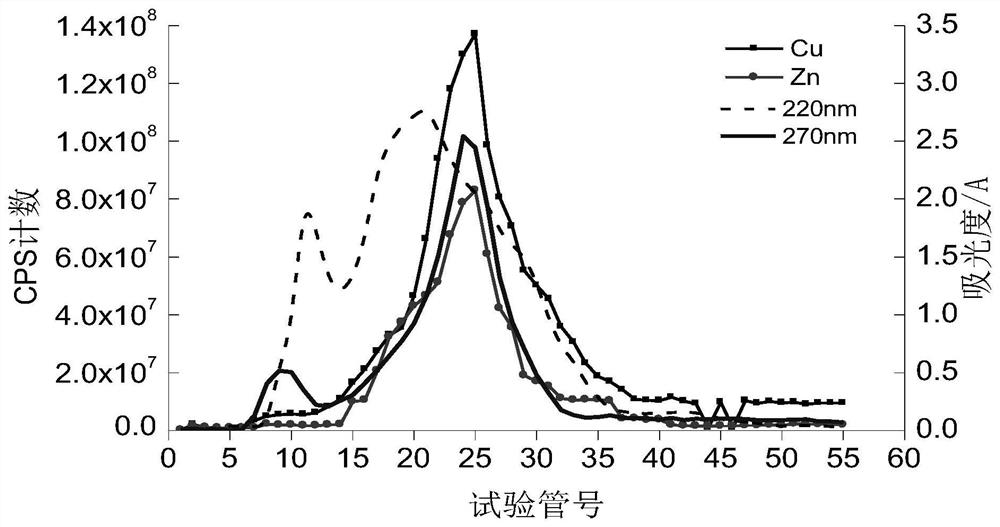

[0042] (2) Sepha...

Embodiment 2

[0053](1) Shrimp shells are removed, the edible part is taken, and Tris-HCl buffer solution with a pH of 7.5 and a concentration of 0.05mol / L is added according to the liquid-to-material ratio of 3:1, stirred and extracted in a water bath at 45°C for 2 hours, and the extract Refrigerate and centrifuge at 10°C and 10000r / min for 20min at high speed, discard the precipitate; collect the supernatant a and heat it in a water bath at 70°C for 7min to remove thermally unstable macromolecular proteins. Centrifuge at 20 min / min for 20 min; after collecting the supernatant b, add 3 times the volume of pre-cooled (temperature 4°C) absolute ethanol, and precipitate overnight at -20°C. After centrifugation at 10°C and 10000r / min for 20min, take the precipitate and add 2-3mL ultrapure water to fully dissolve it, then centrifuge at 4°C, collect the supernatant c and store it at -18°C to obtain Mantis shrimp metallothionein crude extract, referred to as crude extract MT freeze-dried powder; ...

Embodiment 3

[0056] (1) Remove the shells of the shrimps, take the edible part, add the Tris-HCl buffer solution with a pH of 8.0 and a concentration of 0.04mol / L according to the ratio of liquid to material 6:1, stir and extract in a water bath at 55°C for 1.5h, and extract The solution was refrigerated and centrifuged at 6°C and 12000r / min for 30 minutes at high speed, and the precipitate was discarded; the collected supernatant a was heated to 75°C in a water bath for 3 minutes to remove thermally unstable macromolecular proteins, and then rapidly cooled to room temperature and then placed at 6°C, Centrifuge at 12000r / min for 25min; after collecting the supernatant b, add 3 times the volume of pre-cooled (temperature 4°C) absolute ethanol, and precipitate overnight at -20°C. After centrifugation at 6°C and 12000r / min for 25min, take the precipitate and add 2-3mL ultrapure water to fully dissolve it, then centrifuge at 4°C, collect the supernatant c and store it at -18°C to obtain Mantis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com