Control system and method of failure endpoint of high-speed polishing mixed bed

A high-speed mixed bed, end-point control technology, applied in water treatment parameter control, water/sewage treatment, chemical instruments and methods, etc., can solve the problem of increasing the operating pressure of the power plant polishing system, increasing the labor intensity of operators, and the corrosion and salt accumulation of steam turbines. and other problems, to achieve significant environmental protection benefits, energy saving and consumption reduction effects, avoid blind frequent regeneration, and delay performance degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in further detail below in conjunction with accompanying drawing:

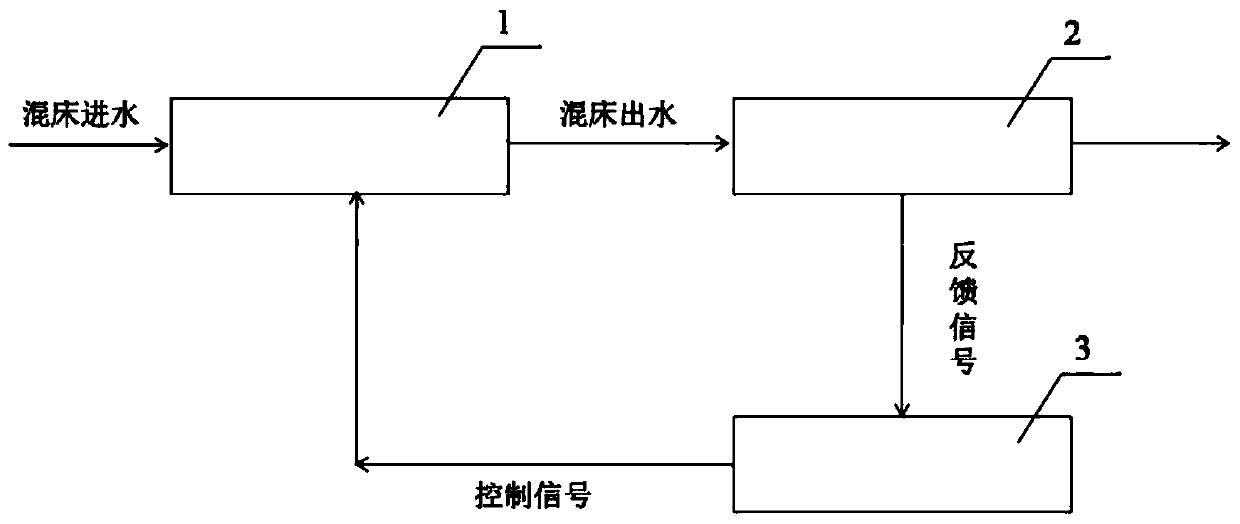

[0014] refer to figure 1 , the fine treatment high-speed mixed bed failure endpoint control system of the present invention includes the high-speed mixed bed 1 of the finishing system and the automatic control system 3 of the failure endpoint of the mixed bed, wherein the outlet pipe of the high-speed mixed bed 1 of the finishing system is provided with a mixed bed The effluent water quality monitoring instrument 2, the output end of the mixed bed effluent water quality monitoring instrument 2 is connected to the input end of the automatic control system 3 for the failure end point of the mixed bed, and the output end of the automatic control system 3 for the end point of the mixed bed is connected to the high-speed mixed bed 1 of the fine treatment system connected to the control terminal.

[0015] Specifically, the mixed bed effluent water quality monitoring instrum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com