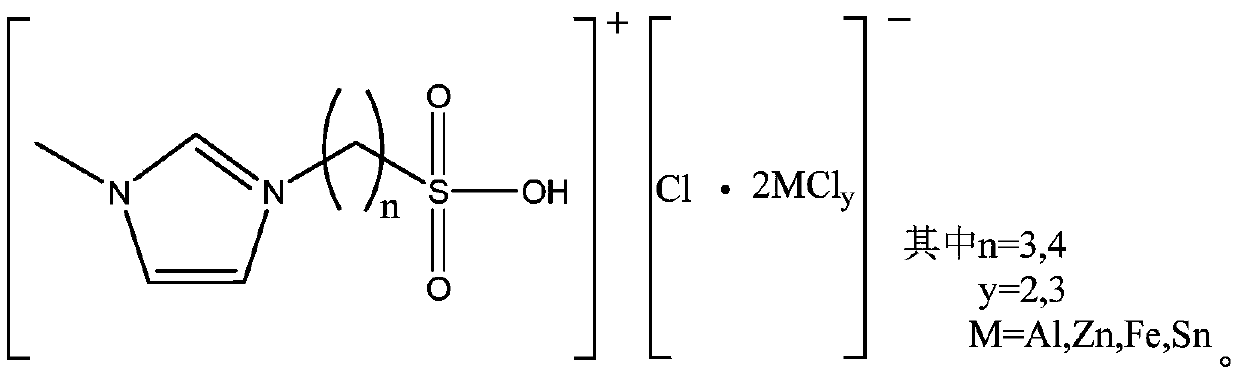

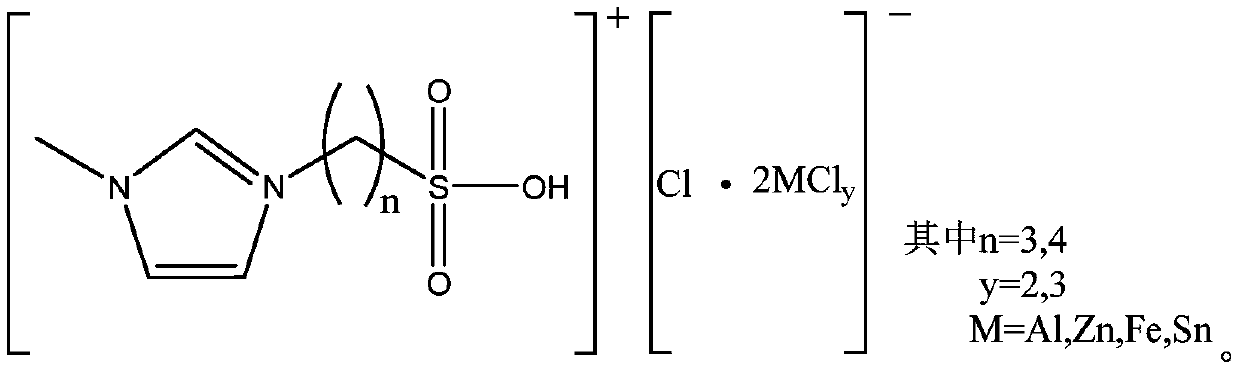

Method for synthesizing alkylated oil form isopentane-propylene under catalysis of dual acidic ionic liquid

A technology of ionic liquid and alkylated oil, which is applied in the field of catalysis, can solve the problems of small number of acid active sites, uneven distribution of acid strength, and increased process cost, so as to increase protonation capacity, reduce energy consumption, and save processing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 40g of isopentane and 6g of 1-sulfopropyl-3-methylimidazolium chloroaluminate bis-acidic ionic liquid catalyst in a 200ml autoclave coated with polytetrafluoroethylene lining, quickly tighten the lid of the kettle, and use N 2 Exhaust the air in the kettle, start the temperature control device, and when the temperature in the kettle is 5°C, use N 2 Punch into the kettle, turn on the stirring device, first stir for 30 minutes to fully mix the catalyst and isopentane, then inject 2g of propylene into the kettle with a micro metering pump, when the reaction pressure is 2MPa, the stirring speed is 1200rpm, and the reaction time is 20min , the mass yield of alkylate (liquid recovery of feed propylene) was 91.5%, and the selectivity of TMPs was 18.4%. After the catalyst was reused 4 times, the mass yield of alkylate was 90.4%, and the selectivity of TMPs was 17.7%.

Embodiment 2

[0023] Add 30g of isopentane and 10g of 1-sulfobutyl-3-methylimidazolium chloride zincate bis-acidic ionic liquid catalyst in a 200ml autoclave with polytetrafluoro-lined lining, quickly tighten the lid of the kettle, and use N 2 Exhaust the air in the kettle, start the temperature control device, and when the temperature in the kettle is 0°C, use N 2 Punch into the kettle, turn on the stirring device, first stir for 30 minutes to fully mix the catalyst and isopentane, then inject 2g of propylene into the kettle with a micro metering pump, when the reaction pressure is 3MPa, the stirring speed is 1000rpm, and the reaction time is 5min , the mass yield of alkylate (liquid recovery of feed propylene) was 86.3%, and the selectivity of TMPs was 18.0%. After the catalyst was reused 6 times, the mass yield of alkylate was 84.7%, and the selectivity of TMPs was 17.2%.

Embodiment 3

[0025] Add 20g isopentane and 4g 1-sulfopropyl group-3-methylimidazolium chlorstannate biacidic ionic liquid catalyst in the autoclave that 200ml is coated with polytetrafluoroethylene liner, tighten still lid rapidly, use N 2 Exhaust the air in the kettle, start the temperature control device, and when the temperature in the kettle is 15°C, use N 2 Punch into the kettle, turn on the stirring device, first stir for 30 minutes to fully mix the catalyst and isopentane, then inject 2g of propylene into the kettle with a micro metering pump, when the reaction pressure is 3MPa, the stirring speed is 600rpm, and the reaction time is 40min , the mass yield of alkylate (liquid recovery of feed propylene) was 80.1%, and the selectivity of TMPs was 15.8%. After the catalyst was reused 5 times, the mass yield of alkylate was 78.8%, and the selectivity of TMPs was 15.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com