Nano filming plugging agent for drilling fluid and preparation method and application of nano filming plugging agent

A technology of drilling fluid and plugging agent, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as easy cracking failure, easy instability of well wall, mechanical instability, etc., to reduce high temperature and high pressure filtration loss The effect of water flow and permeation loss, improvement of mud cake quality and plugging efficiency, high promotion and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A nano film-forming plugging agent for drilling fluids includes the following components: silicon oxide, polyurethane particles, dispersant and alcohols.

[0024] The mass ratio of silicon oxide to polyurethane particles is 1:1, the dispersant is a silicone solution, and the alcohol is a polymeric polyol.

[0025] Nano film-forming plugging agent for drilling fluid, particle size 50~400nm, density 1.05g / cm 3 .

Embodiment 2

[0027] A method for preparing the nano-film-forming plugging agent for drilling fluid according to embodiment 1, including the following steps:

[0028] (1) Weigh silicon oxide and polyurethane particles in mass proportions at room temperature, and then mix them evenly to obtain a mixture;

[0029] (2) Grind the uniform mixture in step (1) to a particle size of 50-400 nm to obtain a uniform fine material;

[0030] (3) The uniform fine material obtained in step (2) is uniformly mixed with the dispersant and the alcohol to obtain a nano film-forming plugging agent for drilling fluid.

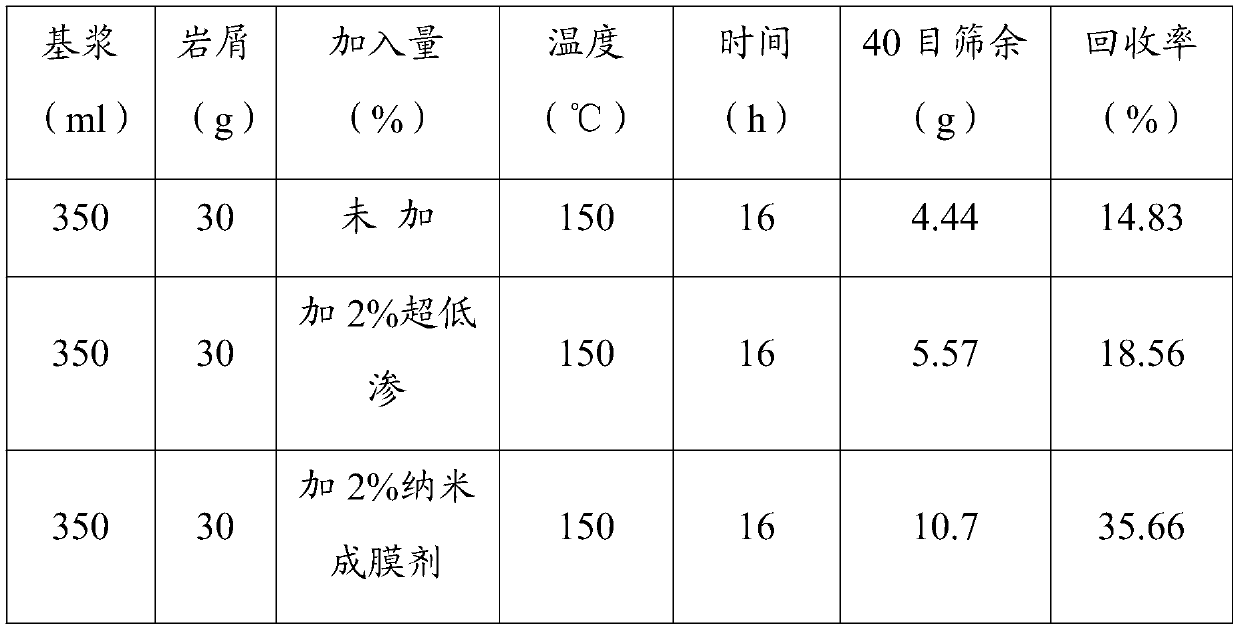

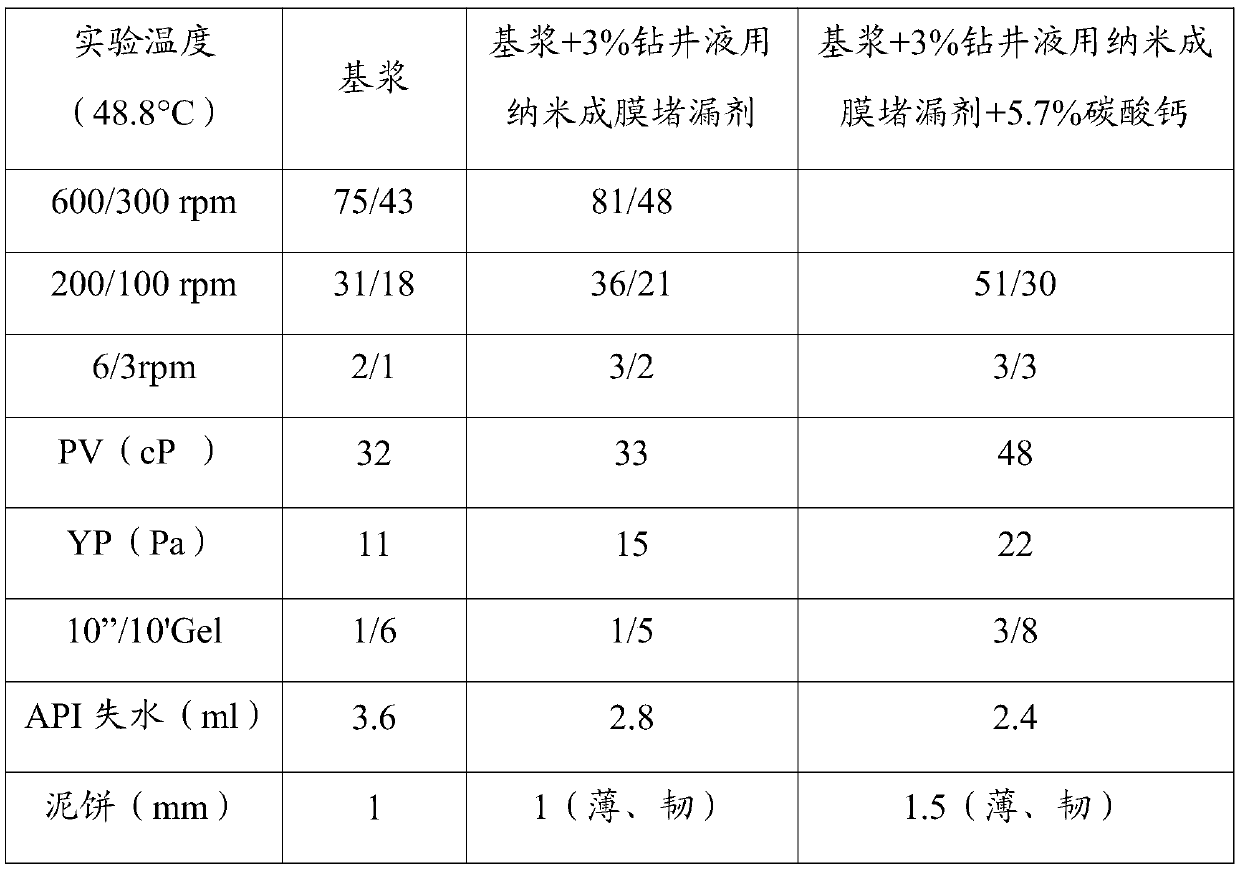

[0031] The technical solution of the present invention will be described below using specific implementation data.

Embodiment 3

[0033] Weigh 19kg of silicon oxide and 19kg of polyurethane particles, mix them evenly, and grind them to a particle size of 300nm. Mix the ground mixture with 90mL of dispersant and 90mL of alcohol to a density of 1.05g / cm 3 , That is, nano film-forming plugging agent for drilling fluid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com