Organosilicon pressure-sensitive adhesive and preparation method thereof

A technology of silicone pressure-sensitive adhesives and pressure-sensitive adhesives, which is applied in the direction of pressure-sensitive films/sheets, adhesives, and adhesive additives. Excellent boiling resistance, excellent cohesive strength, and low peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

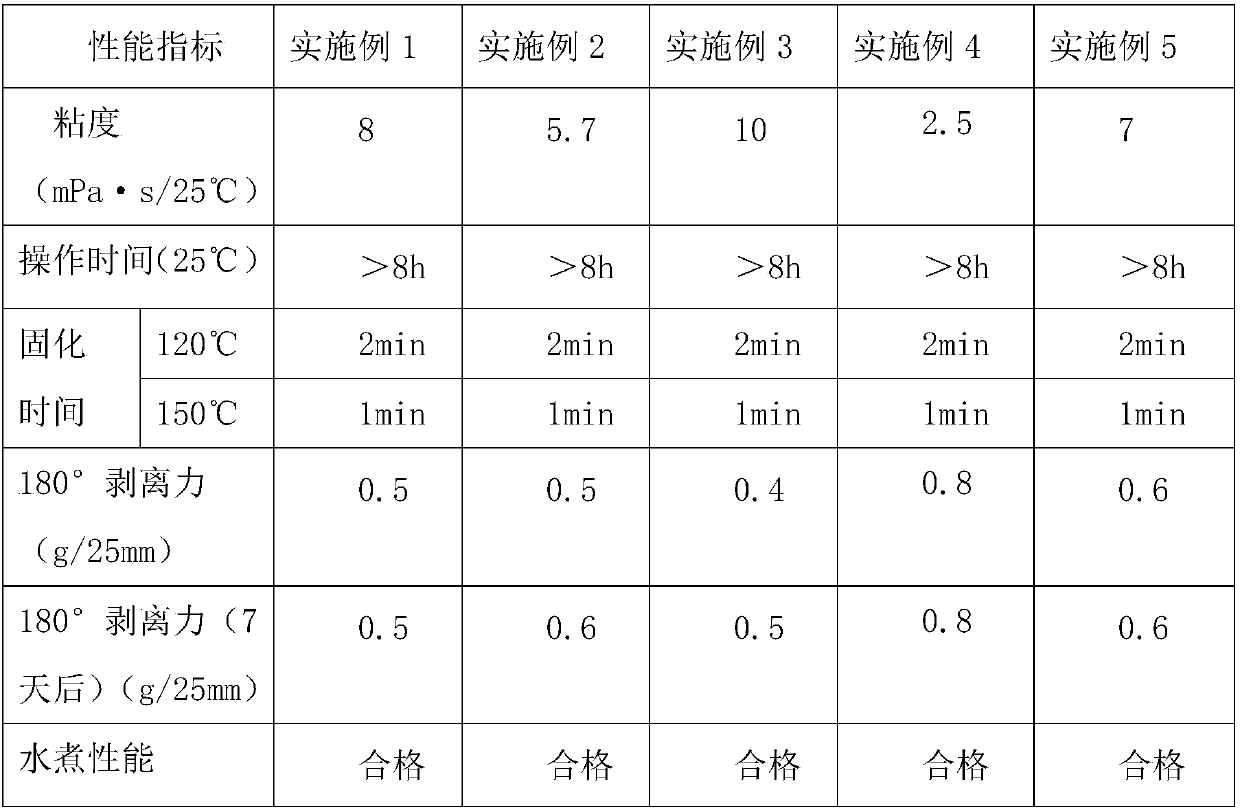

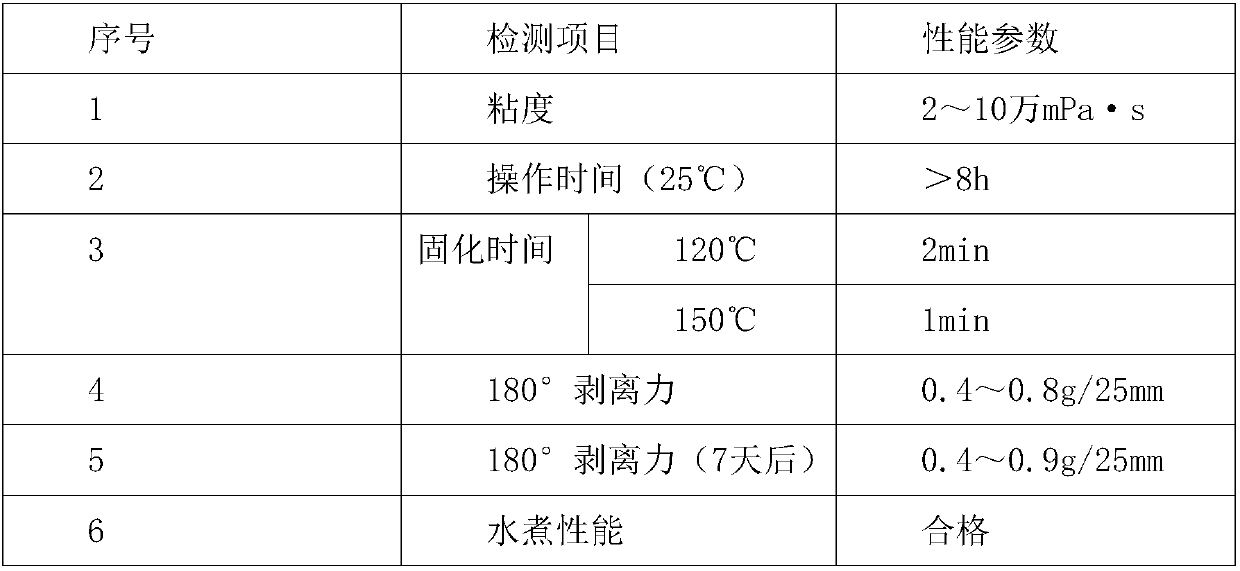

Examples

preparation example Construction

[0033] The preparation method of the gum base component comprises the following steps: adding vinyl polysiloxane with a molecular weight of 500,000 to 700,000 and vinyl polysiloxane with a molecular weight of 5,000 to 20,000 into a reaction kettle, and then adding The diluent is put into the reaction kettle and the vinyl polysiloxane is fully dissolved and dispersed, and then 0.1-2% of the total amount of vinyl polysiloxane is added to the reaction kettle. React in the reactor for 2 to 6 hours under the same conditions, and then distill to remove water, add 0.04 to 0.4 parts of inhibitor in the reactor, and stir evenly; it also includes independent components, and the independent components include base rubber in parts by weight The component is 100 parts, the catalyst component is 0.5-2 parts, the cross-linking agent component is 0.5-2 parts, and the adhesive component is 0.5-1.5 parts.

[0034] The catalyst component is a platinum metal catalyst with a platinum content of 20...

Embodiment 1

[0052] 1) Preparation of base rubber components:

[0053] Add 80 parts of Vinyl Dimethicone A with a vinyl content of 0.2% and 20 parts of Vinyl Dimethicone B with a vinyl content of 0.6% to the reactor, and then add 120 parts of Diluent, stirring, to fully dissolve and disperse vinyl polysiloxane, add 0.1% of the total amount of vinyl polysiloxane basic catalyst, react at 60-80°C for 6 hours under the condition of nitrogen protection, and then heat up When the solvent boils, distill out the reacted water, cool down, add 0.04 part of inhibitor, stir evenly, that is the base rubber component.

[0054] 2) Preparation of pressure sensitive adhesive:

[0055] Add 150 parts of diluent to 100 parts of base glue, and stir evenly; then slowly add 2 parts of crosslinking agent, 1.5 parts of anchoring agent and 2 parts of catalyst under the condition of stirring, and stir for 5-10 minutes after all the addition is complete. Glue preparation is complete.

[0056] 3) Curing of pressure...

Embodiment 2

[0060] 1) Preparation of base rubber components:

[0061] Add 60 parts of Vinyl Dimethicone A with a vinyl content of 0.6% and 20 parts of Vinyl Dimethicone B with a vinyl content of 2.0% to the reactor, and then add 60 parts of Diluent, stirring, to fully dissolve and disperse vinyl polysiloxane, then add 2% of the total amount of vinyl polysiloxane basic catalyst, react for 3 hours at 60-80°C under nitrogen protection, and then Raise the temperature until the solvent boils, distill out the reacted water, cool, add 0.4 part of inhibitor, stir evenly, that is the base rubber component.

[0062] 2) Preparation of pressure sensitive adhesive:

[0063] Add 50 to 150 parts of diluent to 100 parts of base glue, and stir evenly; then slowly add 0.5 parts of crosslinking agent, 1.5 parts of anchoring agent and 2 parts of catalyst under stirring conditions, and stir for 5 to 10 minutes after all additions are completed. The pressure sensitive adhesive is prepared.

[0064] 3) Curin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com