Emulsion for fast-drying, high-gloss, high-weather resistance water-based alkyd paint and preparation method thereof

A water-based alkyd and weather-resistant technology, applied in the direction of coating, etc., can solve the problems that affect the use and promotion of water-based alkyd coatings, the gloss of difficult-to-color paint films, complex processes, etc., and achieve the best weather resistance and chemical resistance. The effect of reducing hydrolysis and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

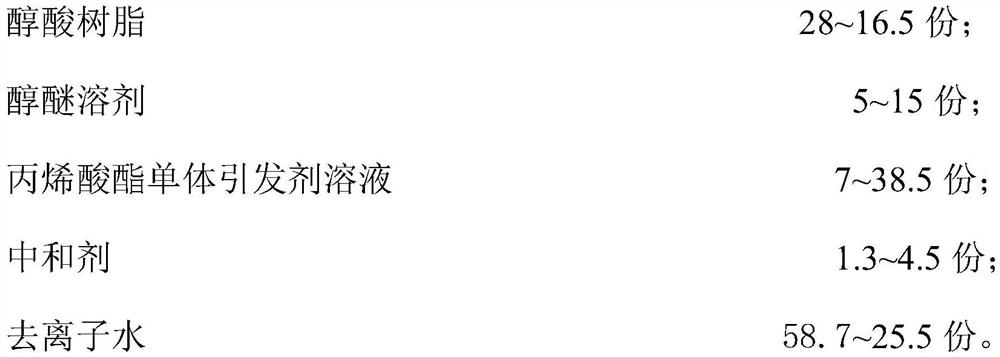

Method used

Image

Examples

preparation example Construction

[0045] The preparation method of emulsion of the present invention, including the following steps:

[0046] Step 1, the preparation of alkyd resins:

[0047]1) Extract high temperature alcohol solution, cooling, cooling, cane, 0.02 parts of glycerol, 0 ~ 3 scrottess, 0.02 parts glycerol, 0 ~ 3 sucrose and 0.02 parts of alcohol solution (calcium oxide or lithium hydroxide) Add 31.48 ~ 28.48 parts of the anhydride, under nitrogen protection, refluxed by refluxed solvent xylene reflux, the temperature rises to 180 ° C, reaction for 1 h, temperature rise to 190 ° C, temperature rise to 220 ° C, esterification reaction;

[0048] Or a mass fraction is 59.5 to 51 parts of dry oleic acid (linoleic acid or dehydrated castor oil) or semi-dried oleic acid (soybean acid) and 20 to 25 parts of benzepine, 20.5 to 24 parts of polyol (glycerol) , Mixture of trimethylolpropane, pentaerythritol or sucrose) is added to the container, under nitrogen protection, refluxed with chlorobenzene in a reflux...

Embodiment 1

[0058] Example 1: (Part 1 synthesis method of alkyd resin in step 1)

[0059] Emulsion synthesis process for quick-dry high-quality high-weathering aqueous alkyd coating:

[0060] The first step, the preparation of alkyd resin: The mass fraction is 53 servoral oil, 15.5 parts of glycerin, 3 parts of sucrose, 0.02 parts of lithium hydroxide, and the four flasks of the condenser, a divider, and the thermometer, Tong nitrogen gas, under nitrogen protection, alcoholysis, dissolve the alcoholic product with ethanol by mass ratio 1: 5, if the ethanol solution of the alcoholic product is clear and transparent, alcoholytic completion, cooling to 180 ° C, add 28.48 parts of beanic anhydride And refluxed xylene, reaction 1 h, temperature rose to 190 ° C for 1 h, warmed to 220 ° C, reaction to an acid value of 16 ± 3 mgKOH / g, resulting a linolel acid resin;

[0061] In the second step, the preparation of acrylic modified alkyd resin: 24.1 parts of a linolenoleic acid resin, 6.9 parts of pr...

Embodiment 2

[0063] Example 2: (Corresponding to the first synthesis method of the alkyd resin in step 1)

[0064] Emulsion synthesis process for quick-dry high-quality high-weathering aqueous alkyd coating:

[0065] The first step, the preparation of alkyd resin: 1 of the mass fraction of 47.5 server, 21 parts of glycerol, 0.02 parts of lithium hydroxide, and the four flasks of the condenser, a divider, and the thermometer, nitrogen gas, Under nitrogen protection, alcoholysis is peroxide, and the alcoholic product is dissolved from 1: 5, and if the ethanol solution of the alcohol product is clear and transparent, the alcohol is completed, cooling to 180 ° C, add 31.48 parts of benzephen and reflow xylene The reaction was 1 h, warmed to 190 ° C for 1 h, warmed to 220 ° C, and the acid value was 10 ± 3 mgKOH / g, resulting in a linolenoleic acid resin;

[0066] In the second step, the preparation of acrylic modified alkyd resin: 21.3 parts of a linenerolate acid resin, 3.0 parts of propylene gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com