A kind of rubber antioxidant and preparation method thereof

A technology of rubber anti-aging agent and amine anti-aging agent, which is applied in the field of rubber anti-aging agent, and can solve the problems affecting the mechanism of anti-aging agent, different molecular volumes, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

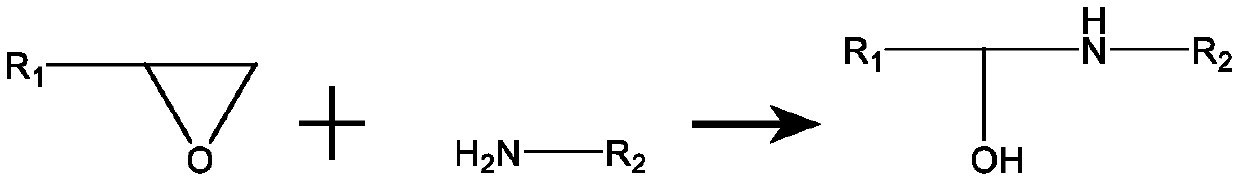

Method used

Image

Examples

Embodiment 1

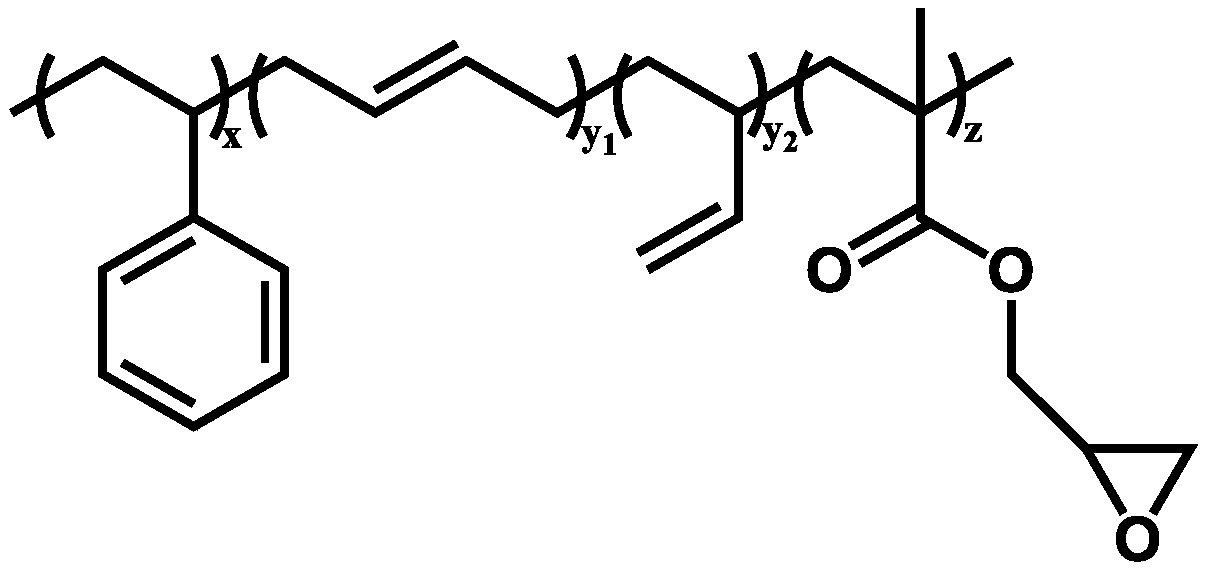

[0032] (1) Preparation of G-ESBR

[0033] G-ESBR was prepared by emulsion polymerization, and the polymerization temperature was 5°C. In the reaction kettle, put DW, DPR aqueous solution, electrolyte aqueous solution (KOH, H 3 PO4, EDTA and Tamol-N mixed aqueous solution), Fe-EDTA aqueous solution, SFS aqueous solution and the mixed solution of monomer ST and GMA, then the reaction kettle is sealed. Vacuumize and fill the sealed reactor with nitrogen for 3 rounds to replace the air atmosphere in the reactor with nitrogen atmosphere. Then inject BD into the kettle, and put the reaction kettle into the polymerization reaction water bath for stirring. After 2 hours, the reactor was taken out, the oxygen scavenger SHS and the initiator PMH were injected, and put back into the reaction water bath to start the polymerization reaction. During the polymerization process, samples were taken regularly, and the conversion rate of the polymerization reaction was calculated by measuring...

Embodiment 2

[0045] (1) Preparation of G-ESBR

[0046] G-ESBR was prepared according to the method described in Example 1.

[0047] (2) crude product purification

[0048] Dissolve G-ESBR in xylene at room temperature. After G-ESBR is completely dissolved, transfer the entire solution to the reactor. At the same time, add anti-aging agent p-aminodiphenylamine PPDA and catalyst triethylenediamine to control G-ESBR The concentration of the anti-aging agent PPDA is 2% of the total, the concentration of the corresponding anti-aging agent PPDA is 0.67% of the total, and the concentration of triethylenediamine is 0.2% of the total. The stirring speed in the vessel was 200 rpm, the reaction was continued for 48 hours, and the heating was stopped to obtain a crude product.

[0049] (3) Separation and purification of reaction products

[0050] Prepare a flocculation detergent methanol six times the volume of the reaction solution, pour the reaction solution into the flocculation detergent for fl...

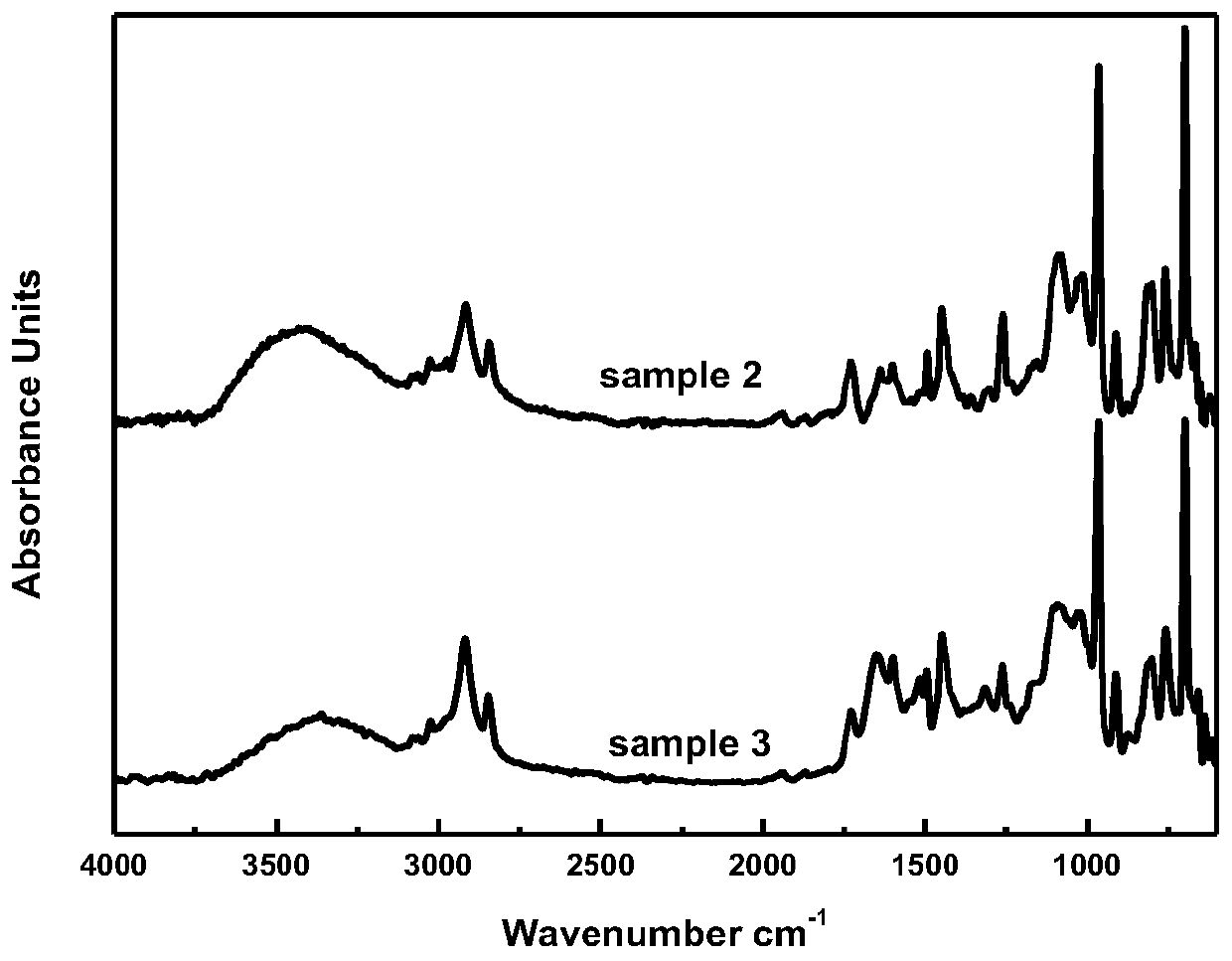

Embodiment 3

[0054] (1) Preparation of G-ESBR

[0055] G-ESBR was prepared according to the method described in Example 1.

[0056] (2) crude product purification

[0057] Dissolve G-ESBR in xylene at room temperature. After G-ESBR is completely dissolved, transfer the entire solution to the reactor. At the same time, add anti-aging agent p-aminodiphenylamine PPDA and catalyst triethylenediamine to control G-ESBR The concentration of the anti-aging agent PPDA is 3% of the whole, the concentration of the corresponding anti-aging agent PPDA is 1% of the whole, and the concentration of triethylenediamine is 0.2% of the whole. The internal stirring speed was 200 rpm, the reaction was continued for 48 hours, and the heating was stopped to obtain a crude product.

[0058] (3) Separation and purification of reaction products

[0059] Prepare a flocculation detergent methanol six times the volume of the reaction solution, pour the reaction solution into the flocculation detergent for flocculati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com