Environmental-friendly boiler deoxidizer

An oxygen scavenger, an environment-friendly technology, applied in the field of environment-friendly boiler oxygen scavenger, can solve problems such as temperature, pH and excess, flammable and explosive, copper ammonia corrosion, etc., and achieve low environmental requirements, Anti-corrosion damage, the effect of environmental protection and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

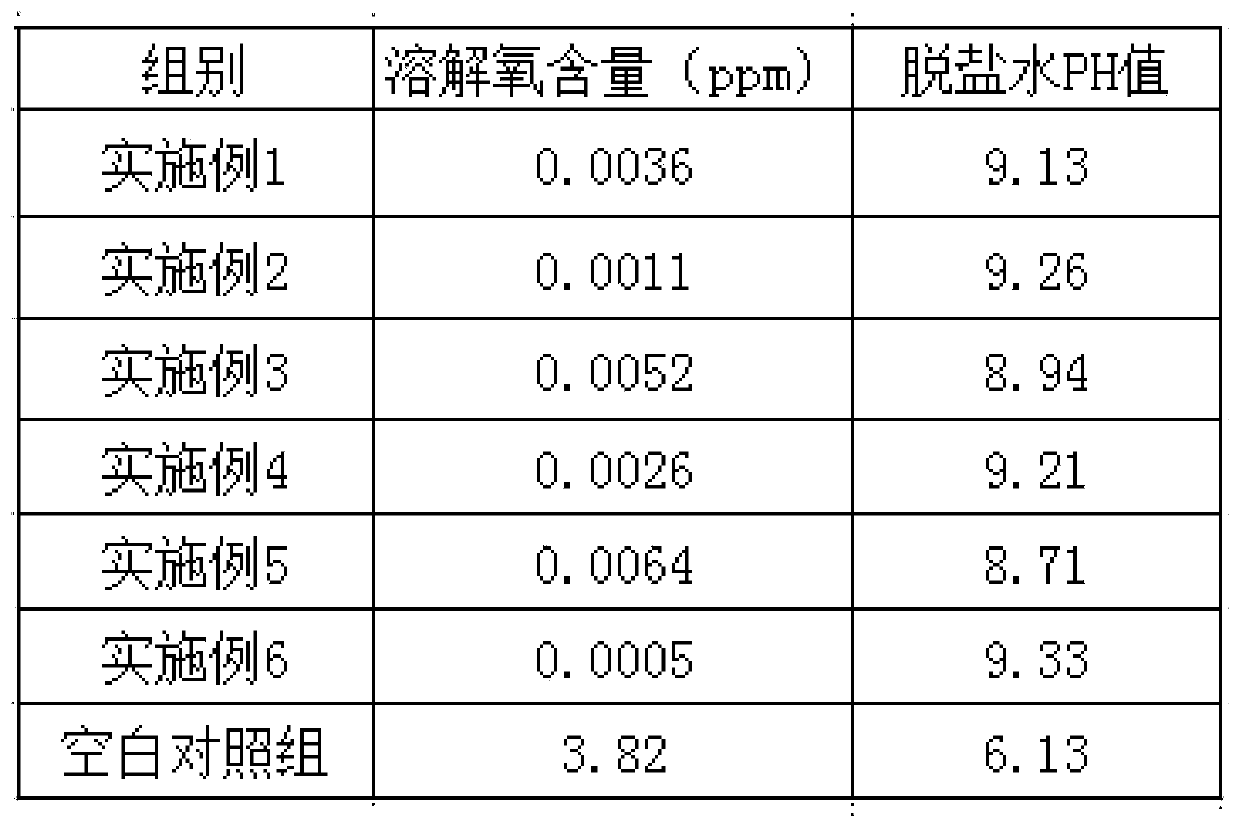

Examples

Embodiment 1

[0019] An environment-friendly boiler oxygen scavenger described in the present invention is made of the following raw materials in parts by weight: 20 parts of acetaldoxime, 9 parts of 1-aminopyrrolidine, 10.5 parts of carbohydrazide, 5 parts of diethylhydroxylamine, 16 parts of neutralizing amine, 1.6 parts of hydroquinone and 37.9 parts of desalinated water.

[0020] The preparation method of the above-mentioned environment-friendly boiler oxygen scavenger: add 37.9 parts of desalted water to the reactor, then add 20 parts of acetaldehyde oxime and 9 parts of 1-aminopyrrolidine to the reactor, stir for 25 minutes; Add 5 parts of diethylhydroxylamine and 16 parts of neutralizing amine in the reaction kettle, stir for 37 minutes; finally add 10.5 parts of carbohydrazide and 1.6 parts of hydroquinone to the reaction kettle, stir for 12 minutes, and let it stand for 10 minutes to obtain The environment-friendly boiler oxygen scavenger.

Embodiment 2

[0022] An environment-friendly boiler oxygen scavenger described in the present invention is made of the following raw materials in parts by weight: 20 parts of propionaldehyde oxime, 9 parts of 1-aminopyrrolidine, 10.5 parts of carbohydrazide, 5 parts of diethylhydroxylamine, 16 parts of neutralizing amine, 1.6 parts of hydroquinone and 37.9 parts of desalinated water.

[0023] The preparation method of the above-mentioned environment-friendly boiler oxygen scavenger: add 37.9 parts of desalted water to the reactor, then add 20 parts of propionaldehyde oxime and 9 parts of 1-aminopyrrolidine to the reactor, stir for 25 minutes; Add 5 parts of diethylhydroxylamine and 16 parts of neutralizing amine in the reaction kettle, stir for 37 minutes; finally add 10.5 parts of carbohydrazide and 1.6 parts of hydroquinone to the reaction kettle, stir for 12 minutes, and let it stand for 10 minutes to obtain The environment-friendly boiler oxygen scavenger.

Embodiment 3

[0025] A kind of environment-friendly boiler oxygen scavenger described in the present invention is made of the raw materials of following weight parts: 20 parts of propionaldehyde oxime, 9 parts of 1-aminopyrrolidine, 10.5 parts of glyoxalhydrazine, 5 parts of diethylhydroxylamine, 16 parts of neutralizing amine, 1.6 parts of hydroquinone and 37.9 parts of desalinated water.

[0026] The preparation method of the above-mentioned environment-friendly boiler oxygen scavenger: add 37.9 parts of desalted water to the reactor, then add 20 parts of propionaldehyde oxime and 9 parts of 1-aminopyrrolidine to the reactor, stir for 25 minutes; Add 5 parts of diethylhydroxylamine and 16 parts of neutralizing amine in the reaction kettle, stir for 37 minutes; finally add 10.5 parts of glyhydrazine and 1.6 parts of hydroquinone to the reaction kettle, stir for 12 minutes, and let it stand for 10 minutes to obtain The environment-friendly boiler oxygen scavenger.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com