Silicon powder surface deoxidizing method

A silicon powder, anhydrous ethanol technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of hindering the removal of residual oxides, eroding and damaging the silicon substrate, and reducing the efficiency of oxygen removal, and achieving a rapid removal reaction. , lower contact angle, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

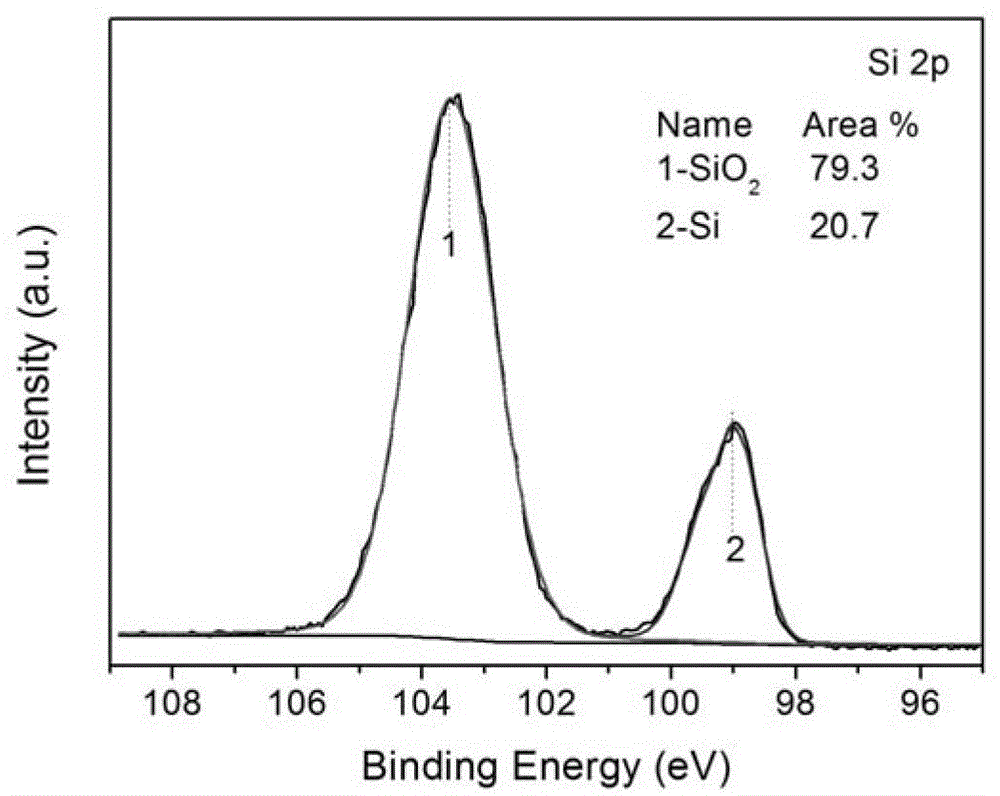

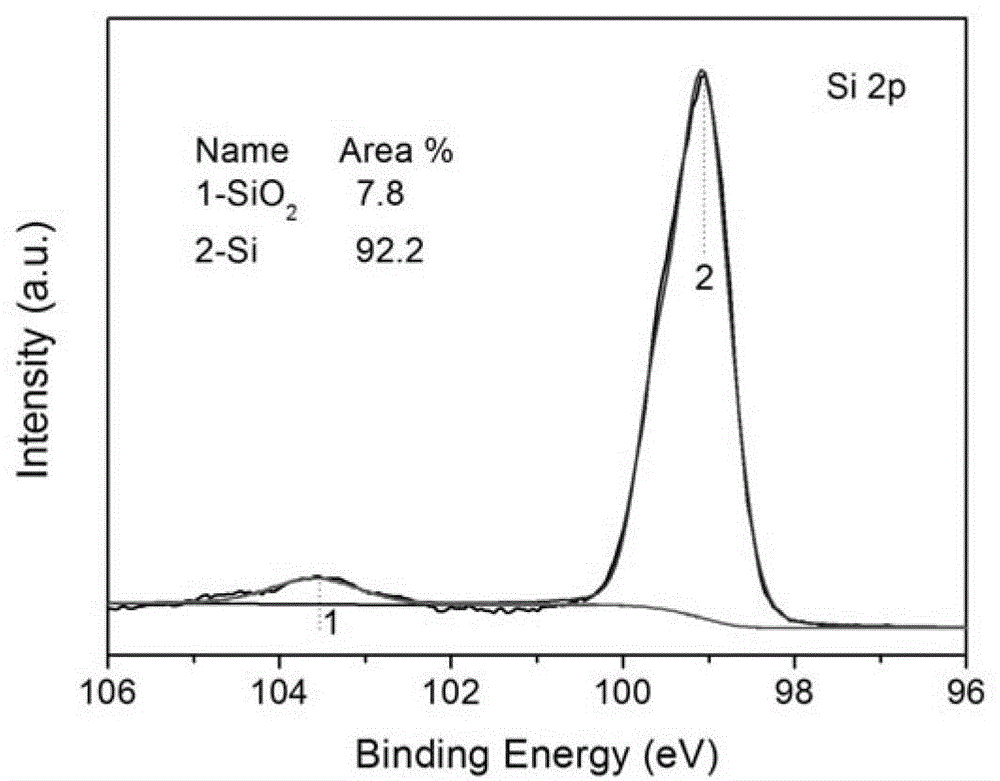

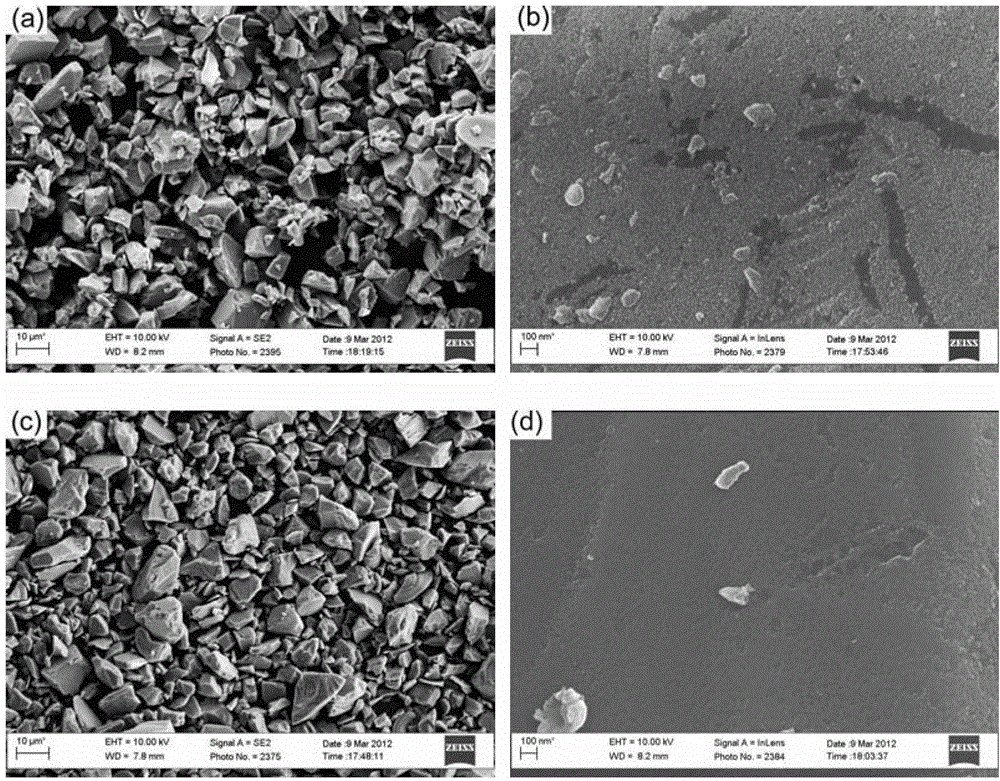

[0012] The commercial silica fume has a purity of 99.999 wt%, an average particle size of 6.23 μm, and an oxygen content of 2900 ppm. figure 1 is the XPS spectrum of original commercial silicon powder Si2p, SiO 2 The peak area ratio is 79.3%, it can be seen that the surface oxidation of silicon powder is serious. The nominal composition of deaeration liquid is by volume percentage, HF: 4%, C 2 h 5 OH: 2%, the rest is deionized water. Prepare the required oxygen removal solution in proportion and place it in a constant temperature water bath at 50°C, take out an appropriate amount of original commercial silicon powder to be treated and put it into the oxygen removal solution, stir continuously for 30 minutes, and then wash and filter with deionized water through a vacuum filter for 5 Once, vacuum-dried at 50°C, and then immediately vacuum-packed and stored. After testing, the oxygen content in the silicon powder dropped to (242±30) ppm after oxygen removal. figure 2 It is...

Embodiment approach 2

[0014] The commercial silica fume has a purity of 99.9 wt%, an average particle size of 26.67 μm, and an oxygen content of 3500 ppm. The nominal composition of deaeration liquid is by volume percentage, HF: 15%, C 2 h 5 OH: 3%, the rest is deionized water. Prepare the required oxygen removal solution in proportion and place it in a constant temperature water bath at 50°C, take out an appropriate amount of original commercial silicon powder to be treated and put it into the oxygen removal solution, stir continuously for 30 minutes, and then wash and filter with deionized water through a vacuum filter for 5 Once, vacuum-dried at 50°C, and then immediately vacuum-packed and stored. After testing, the oxygen content in the silicon powder dropped to (440±50) ppm after oxygen removal.

Embodiment approach 3

[0016] The commercial silica fume has a purity of 99.9 wt%, an average particle size of 26.67 μm, and an oxygen content of 3500 ppm. The nominal composition of deaeration liquid is by volume percentage, HF: 1%, C 2 h 5 OH: 0.5%, the rest is deionized water. Prepare the required oxygen removal solution in proportion and place it in a constant temperature water bath at 50°C, take out an appropriate amount of original commercial silicon powder to be treated and put it into the oxygen removal solution, stir continuously for 30 minutes, and then wash and filter with deionized water through a vacuum filter for 5 Once, vacuum-dried at 50°C, and then immediately vacuum-packed and stored. After testing, the oxygen content in the silicon powder dropped to (700±40) ppm after oxygen removal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com