Schiff base polymer/carbon nanotube composite electrode material with shish-kebab structure and preparation method of Schiff base polymer/carbon nanotube composite electrode material

A carbon nanotube composite and electrode material technology, which is applied in the direction of carbon nanotubes, nanocarbons, battery electrodes, etc., can solve the problems of small specific surface area of polymers, low utilization rate of functional groups, poor conductivity, etc., and achieve good structural stability. High yield and the effect of increasing electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation:

[0028] 1) Weigh 0.0608 acidified carbon nanotubes into a 250mL round bottom flask, add 80mL of toluene, and sonicate for 30min to fully disperse the carbon nanotubes.

[0029] 2) Add 0.3357g terephthalaldehyde into the round bottom flask, start stirring to completely dissolve the terephthalaldehyde.

[0030] 3) Add 0.2708g of p-phenylenediamine, turn on the protection of argon under stirring, and heat to 150° C. for reflux for 6 hours.

[0031] 4) After the reaction, turn off the heating, stop the stirring after the solution is cooled to room temperature, filter under reduced pressure and wash the product fully with ethanol; dry the product at 80°C for 12 hours, collect the product as a black solid powder, which is a skewered crystal structure mat Phosphate base polymer / carbon nanotube composite electrode material.

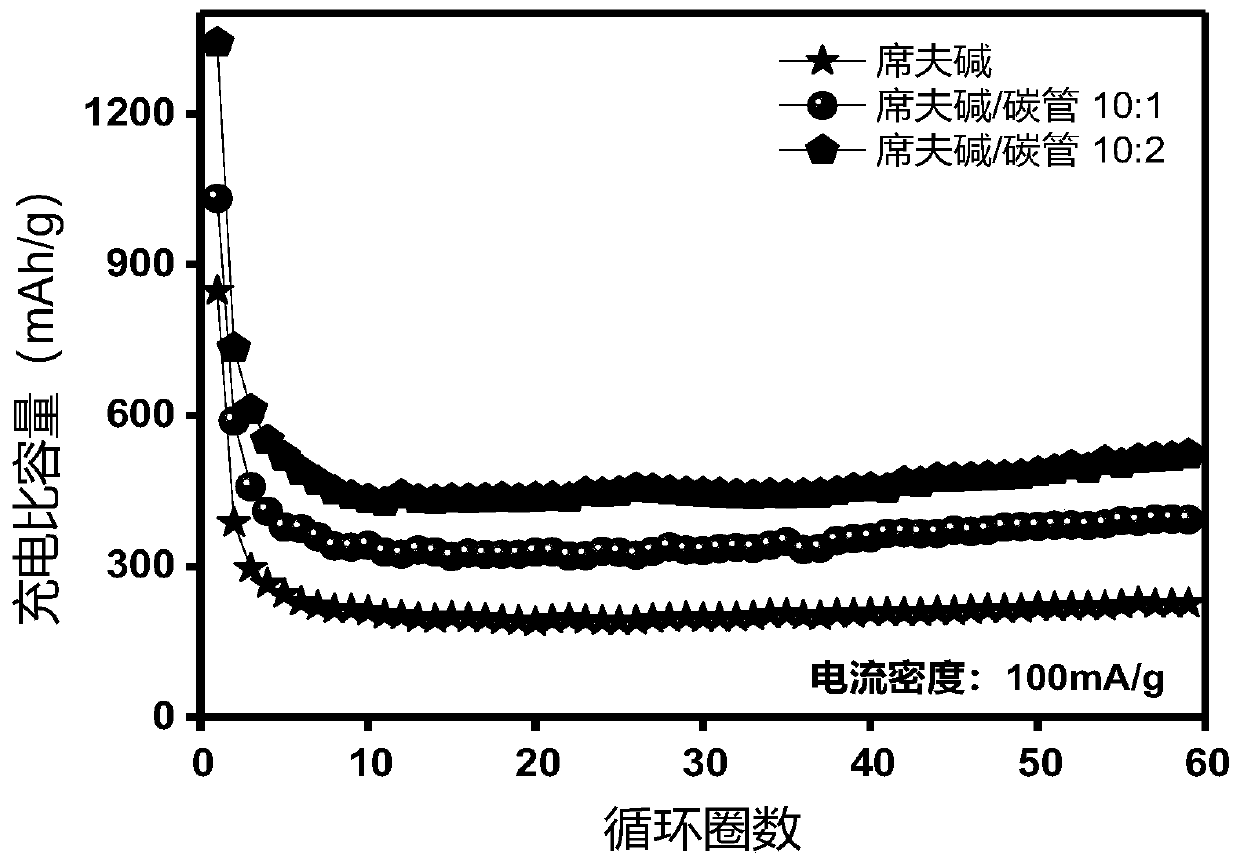

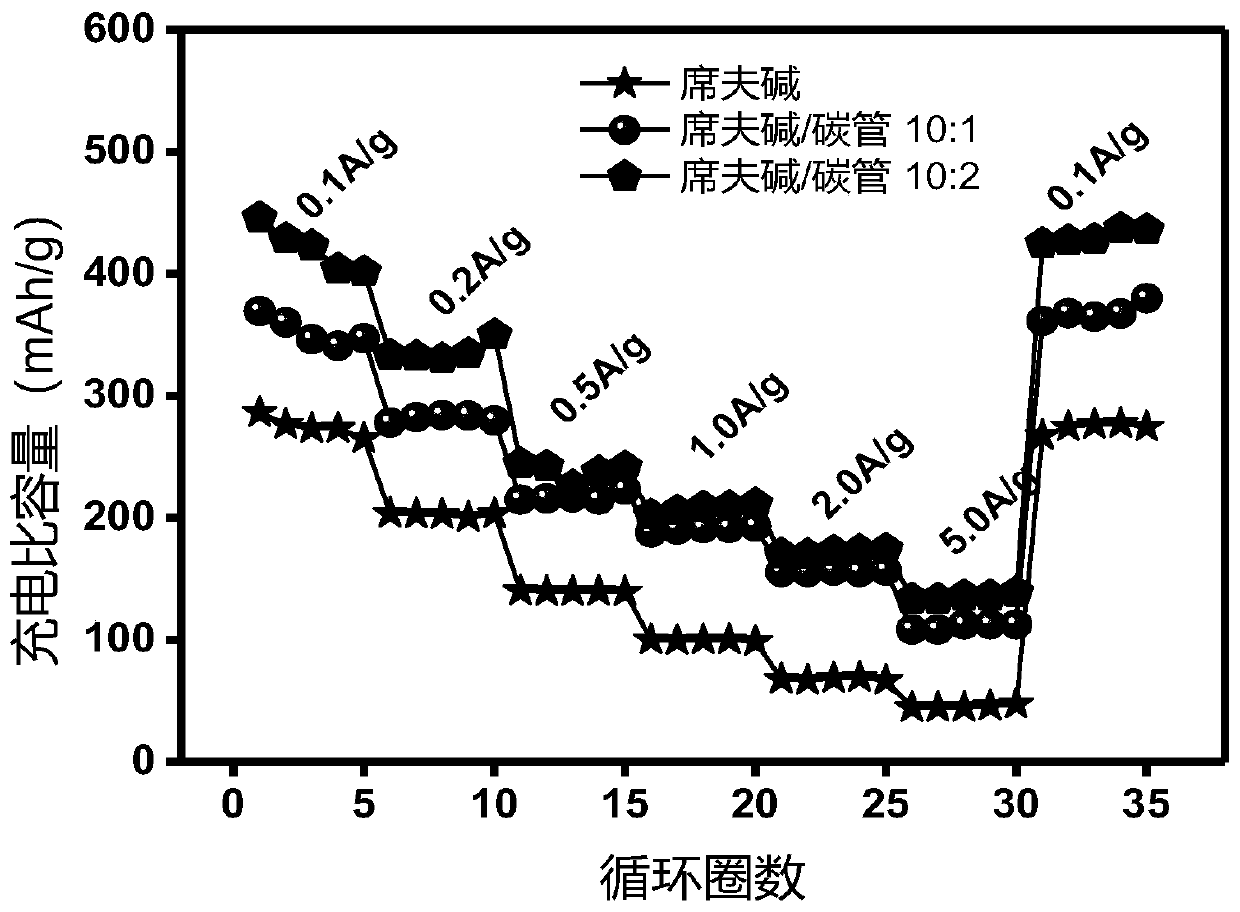

[0032] In the composite electrode material prepared in Example 1, the mass ratio of the Schiff base polymer to the carbon nanotube is abou...

Embodiment 2

[0038] Preparation:

[0039] 1) Weigh 0.1212 acidified carbon nanotubes into a 250mL round bottom flask, add 80mL of toluene, and sonicate for 30min to fully disperse the carbon nanotubes.

[0040] 2) Add 0.3357g terephthalaldehyde into the round bottom flask, start stirring to completely dissolve the terephthalaldehyde.

[0041] 3) Add 0.2708g of p-phenylenediamine, turn on the protection of argon under stirring, and heat to 150° C. for reflux for 6 hours.

[0042] 4) After the reaction, turn off the heating, stop the stirring after the solution is cooled to room temperature, filter under reduced pressure and wash the product fully with ethanol; dry the product at 80°C for 12 hours, collect the product as a black solid powder, which is a skewered crystal structure mat Phosphate base polymer / carbon nanotube composite electrode material.

[0043]In the composite electrode material prepared in Example 2, the mass ratio of the Schiff base polymer to the carbon nanotube is about...

Embodiment 3

[0050] Preparation:

[0051] 1) Weigh 0.0971g of acidified carbon nanotubes into a 250mL round bottom flask, add 80mL of ethanol, and sonicate for 30min to fully disperse the carbon nanotubes.

[0052] 2) Add 0.3357g terephthalaldehyde into the round bottom flask, start stirring to completely dissolve the terephthalaldehyde.

[0053] 3) Add 170 μL of ethylenediamine, turn on argon protection under stirring, and heat to 80° C. for 6 hours under reflux.

[0054] 4) After the reaction, turn off the heating, stop the stirring after the solution is cooled to room temperature, filter under reduced pressure and wash the product fully with ethanol; dry the product at 80°C for 12 hours, collect the product as a black solid powder, which is a skewered crystal structure mat Phosphate base polymer / carbon nanotube composite electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com